Buyer Guide

1000w Hand-Held Laser Cleaning Machine for Rust Removal

Hand-held laser cleaning machines with 1000w laser souce are innovative tools designed for rust removal and surface cleaning applications. These devices utilize laser technology to effectively remove rust, oxides, and contaminants from various materials without the need for chemical solvents or abrasive techniques. Laser cleaning machines offer several advantages over traditional methods, such as reduced labor, increased precision, and environmental friendliness.

Hand-held laser cleaning machines offer several benefits, including

Non-contact Cleaning: Laser cleaning is a non-abrasive and non-contact process, which means there is minimal risk of damaging the material being treated. It is particularly useful for cleaning delicate or complex surfaces.

Precision and Selectivity: Laser cleaning allows precise control over the cleaning parameters, making it possible to selectively remove rust and contaminants without affecting the underlying material.

Eco-Friendly: Unlike traditional cleaning methods that often involve chemicals or generate hazardous waste, laser cleaning is environmentally friendly. It eliminates the need for chemical solvents and minimizes waste generation.

Time and Cost Savings: Laser cleaning machines can remove rust and contaminants quickly and efficiently, reducing labor costs and downtime associated with manual cleaning methods.

Adjustable Parameters:

Look for machines with adjustable parameters such as power, pulse duration, and frequency. Adjustable settings allow for customization based on the specific material and the level of contamination.

A 1000W laser implies a high-power device suitable for more demanding applications. Higher wattage can mean faster and more effective cleaning, but it also requires careful use to avoid damaging the substrate.Hand-held laser cleaning machines are commonly used in various industries, including automotive, aerospace, maritime, manufacturing, and restoration.

Here’s how a hand-held laser cleaning machine for rust removal typically works

- Laser Generation: The machine incorporates a laser source, commonly a fiber laser, which emits a high-intensity laser beam of a specific wavelength. The wavelength is selected based on the material being treated and the type of contaminants to be removed.

- Laser Delivery: The laser beam is transmitted through an optical fiber or a series of mirrors to a hand-held cleaning head. The cleaning head usually consists of a focusing lens that concentrates the laser energy into a small spot size.

- Cleaning Process: When the focused laser beam impacts the surface of the material, it interacts with the rust or contaminants. The high energy of the laser beam causes rapid heating and vaporization of the rust or contaminants, resulting in their removal from the surface.

- Surface Protection: To prevent damage to the underlying material, the laser cleaning machine is equipped with a control system that monitors parameters such as power, pulse duration, and scanning speed. This ensures that only the rust or contaminants are removed while preserving the integrity of the surface.

- Waste Collection: The removed rust or contaminants are typically converted into vapor or particulate matter. Some laser cleaning machines incorporate a vacuum system to collect and filter the waste for safe disposal.

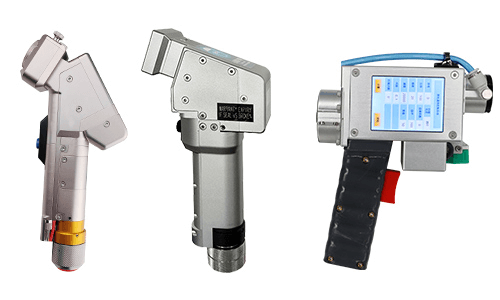

Cleaning Head:

The cleaning head is the part of the device that contains the laser beam delivery system. It typically consists of focusing optics, such as lenses or mirrors, that shape and focus the laser beam to a desired spot size on the surface being cleaned. The cleaning head is designed to be handheld and maneuverable, allowing operators to target specific areas for rust removal.

Portable Design:

Handheld laser cleaning machines are designed to be portable and lightweight, allowing operators to easily move and manipulate the device during rust removal operations. This flexibility enables the cleaning of various surfaces, including large and complex structures.

Cooling System:

Laser cleaning generates heat, and a cooling system is integrated into the handheld device to dissipate excess heat and maintain optimal operating temperatures. This helps to ensure the longevity and performance of the laser source and other components.

It’s important to note that the specific features, capabilities, and configurations of handheld laser cleaning machines can vary depending on the manufacturer and model.recommended to consult with us to determine the most suitable handheld laser cleaning machine for your specific rust removal needs.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.