Buyer Guide

3015 Pipe and Sheet Laser Cutting Machine 2000w 3000w 4000w

Pipe and Sheet Laser Cutting Machine

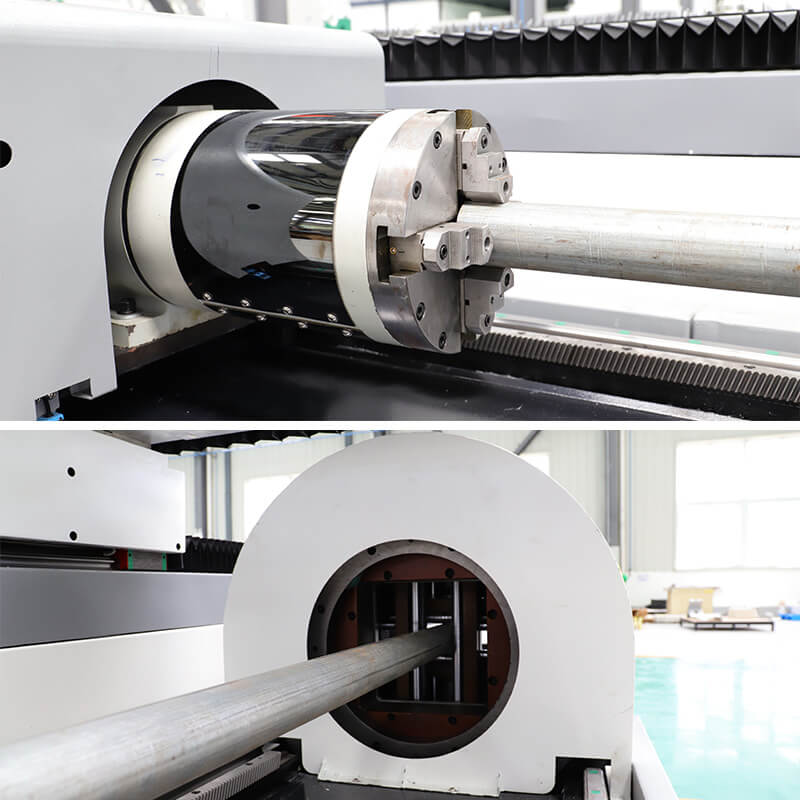

A 3015 Pipe and Sheet Laser Cutting Machine is a type of laser cutter designed to cut both flat sheets and pipes or tubes. the size of the working area, with 3000mm x 1500mm being a common size for the cutting bed.The 3015 pipe and sheet laser cutting machine is equipped with a specialized rotary device that allows for the cutting of both flat sheets and cylindrical pipes or tubes. This versatility makes it suitable for a wide range of applications in industries such as metal fabrication, automotive, aerospace, and more.

The machine can efficiently cut flat sheets of various materials, including metals like steel, stainless steel, aluminum, and non-metals like acrylic, wood, and plastics. It provides precise and clean cuts, allowing for complex shapes and intricate designs to be achieved.

These machines often come with advanced software programs that allow for easy importation and manipulation of design files. The software can optimize cutting paths, reduce material waste, and increase efficiency. Additionally, some machines can be integrated into automated production lines for enhanced productivity.Laser cutting machines offer exceptional precision and accuracy, resulting in clean and smooth cuts without the need for additional finishing processes. This level of precision ensures tight tolerances and enables the production of high-quality parts and components.

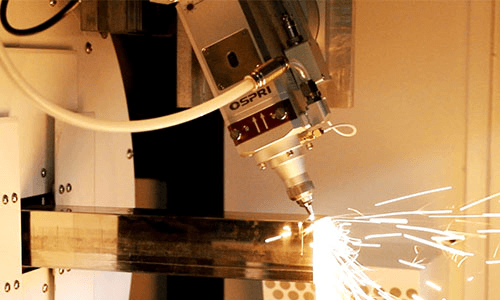

Laser cutting machines can perform both cutting and engraving operations. Cutting involves the laser beam melting, burning, or vaporizing the material along a predefined path to create a clean, precise cut. Engraving, on the other hand, involves etching or marking the material’s surface with the laser beam to create text, logos, or intricate designs.Laser cutting is a non-contact process, which minimizes material waste compared to traditional cutting methods. The precision of laser cutting allows for tight nesting of parts, maximizing material usage and reducing costs.

The 3015 pipe and sheet laser cutting machine operates at high speeds, allowing for efficient production and quick turnaround times. It can handle complex cutting patterns and contours, optimizing productivity for both sheet and pipe cutting operations.

What Is a Laser Cutting Machine ?

The fiber laser cutting machine for sale, also known as the metal laser cutting machine or metal laser cutter, is the laser machine adopting fiber laser source to cut steel, carbon steel, stainless steel, copper, brass, aluminum, iron, galvanized steel, titanium and various alloys. It has wide applications in metal part, equipment, ship, and automotive manufacturing, advertising signs, sheet metal structure, kitchenware, metal furniture, custom metal fabrication, and other fields.

The fiber laser cutter, based on functions, falls into the laser cutting machine for metal sheet, fiber laser tube cutting machine, and sheet and tube laser cutting machine. Each model of the fiber laser machine has multiple specifications and configurations.

Based on the fiber laser power, we provide 1000W / 1500W / 2000W / 3000W / 4000W / 6000W / 8000W fiber laser cutting machine and other high power laser cutting machines to realize your metal cutting designs, ideas, and plans.

In addition, there are multiple worktable sizes available for the laser sheet cutting machine. For example, 1530 fiber laser cutting machine, 1540 laser sheet cutting machine, 2040 CNC fiber laser cutter, 1560 sheet metal laser cutter, 2040 fiber laser cutting machine , 2060 fiber laser cutter, etc. Feel free to contact us if you want to know more about the fiber laser cutting system or the laser cutting service.

Advantages of CNC fiber laser cutter?

1. Good beam quality. The waveguide structure of the fiber laser determines that it is easy to obtain a single transverse mode output. Besides, it is unlikely to be affected by external factors, which can achieve high brightness laser output.

2. High efficiency. The overall electro-optical efficiency of commercial fiber lasers is as high as 25%, which is conducive to cost reduction, energy-saving, and environmental protection.

3. Good heat dissipation. The CNC fiber laser uses thin rare earth element doped fibers as the gain medium, which has a very large surface area to volume ratio. This is conducive to heat dissipation. The water-cooling method for high-power fiber laser can avoid the loss of quality and efficiency caused by the heat effect.

4. Compact structure and high reliability. Since the fiber laser uses fine and flexible fiber as the gain medium, it helps to compress the size and save cost.

5. Maintenance free. There is no optical lens in the resonant cavity of the CNC fiber laser. So it has the advantages of adjustment-free, maintenance-free, and high stability, which is incomparable to traditional lasers.

Application of the fiber laser cutting machine

Fiber laser cutting machines can cut many kinds of metal plates and tubes. It is mainly suitable for cutting stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized plate, aluminized zinc plate, pickled plate, copper, silver, gold, and other metal plates and tubes.

The fiber laser cutting machine has wide application fields. For example, thin metal sheet processing, advertising signs, electric cabinets, mechanical parts, kitchenware, automobile, equipment, crafts, arts, electronic boards, medical equipment, instruments, tools, etc.

Why choose the fiber laser cutting machine?

- High cutting accuracy.The positioning accuracy of the metal laser cutter reaches 0.03 mm, and the repeated positioning accuracy reaches 0.02 mm.

- Narrow slit. The width of the slit is generally 0.10-0.20 mm.

- Smooth cutting surface. There is no burr on the cutting surface, and the roughness of the cut surface is generally controlled within Ra6.5.

- Fast cutting speed. The cutting speed of a fiber laser cutter can reach 60m/min. And the maximum running speed of a fiber laser metal sheet cutting machine can reach 140m/min.

- Good cutting quality: Adopting non-contact cutting, there is basically no thermal deformation and damage of the workpiece. Besides, the cutting surface generally requires no further processing.

- Flexible operation. The fiber laser cutting machine has good flexibility to cut any patterns. It can also cut various regular and irregular-shaped tubes and steel bars.

- Long service life. A top-rated fiber laser has high photoelectric conversion rate and stable performance. The service life of the major parts of a fiber laser cutting machine could reach 100,000 hours.

- Less maintenance. The laser of laser metal cutters for sale is transmitted by optical fibers instead of optical lenses. So there is no need to adjust the optical path and replace lenses frequently, which reduces many maintenance costs.

- Strong adaptability. The laser cutting machine for metal sheet is capable of handling any harsh working environment. It also has strong adaptability to dust, vibration, impact, humidity, and temperature.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.