Buyer Guide

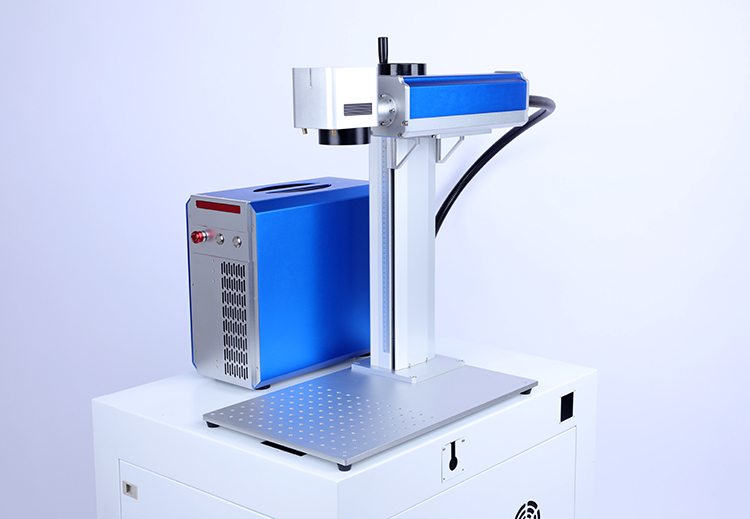

5w UV Laser Marking Machine

Introduction of UV laser marking machine

The 5W ultraviolet laser marking machine belongs to the series of laser marking machines. It incorporates international advanced technology. High-energy ultraviolet photons directly destroy the molecular bonds on the surface of many non-metallic materials and make the molecules separate from the object. This method will not produce high The heat, the UV laser spotlight is very small, and the processing has almost no thermal damage, so it is called cold processing. The UV laser marking machine is developed by using a 355nm UV laser. The machine uses a third-order intracavity frequency doubling technology. Compared with infrared lasers, the 355 ultraviolet light has a very small focus spot, which can greatly reduce the mechanical deformation of the material and has little processing heat impact, because it is mainly used for ultra-fine marking and engraving, and is especially suitable for food and medical packaging materials. Marking, micro-hole drilling, high-speed division of glass materials, and complex pattern cutting of silicon wafers!

UV Laser Marking Machine PARAMETERS

Features of UV laser marking machine

1. Due to the extremely small focusing spot and the small processing heat-affected zone, the ultraviolet laser can perform ultra-fine marking and is the first choice for customers who have higher requirements for marking effects;

2. In addition to copper materials, UV lasers have a wider range of materials suitable for processing;

3. Not only the beam quality is good, but the focused spot is smaller, which can realize ultra-fine marking;

4. The scope of application is more extensive; the heat-affected area is extremely small, no thermal effect will be produced, and no material burning problem will occur;

5. Fast marking speed and high efficiency; the whole machine has the advantages of stable performance, small size and low power consumption;

UV laser marking machine equipment application

1. Suitable for surface marking and micro-hole processing of glass, polymer materials and other objects;

2. Widely used in marking the surface of packaging bottles (boxes) of food, medicine, cosmetics, wires and other polymer materials;

3. Flexible PCB board, LCD, TFT marking, dicing and cutting, etc.;

4. Removal of metal or non-metal coating;

5. Micro-hole and blind hole processing of silicon wafers;

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.