Plasma Cutting Machine Application

Plasma cutting is a metal cutting process that uses a high-velocity jet of ionized gas, known as plasma, to melt and remove material from a workpiece. It is a versatile and efficient method for cutting a wide range of conductive materials, including steel, aluminum, stainless steel, and copper. Plasma cutting is a versatile and efficient method for metal cutting and is widely used in industries that require precision and speed in material processing.

-

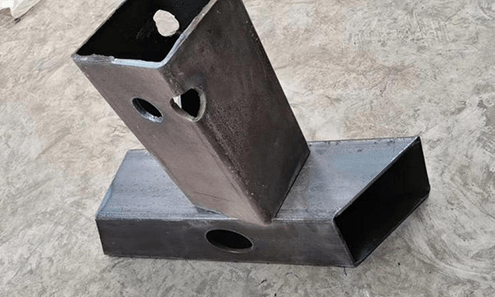

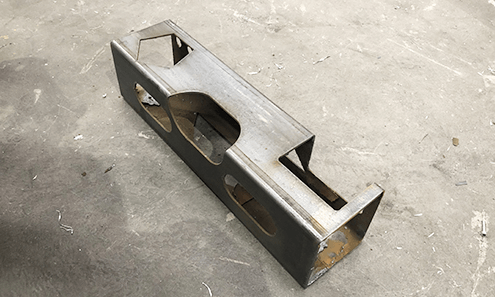

Metal Fabrication: Cutting sheet metal, plates, and structural components for various industries, including automotive, aerospace, and construction.

-

Industrial Manufacturing: Producing parts and components for machinery and equipment.

-

Shipbuilding: Cutting and shaping metal components for ship construction.

-

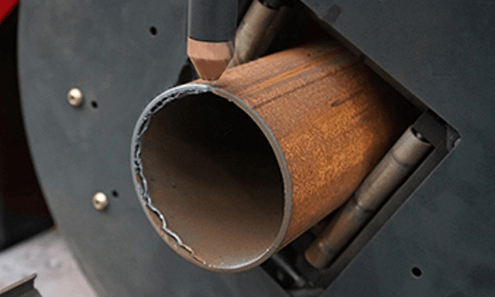

Construction: On-site cutting of steel beams, pipes, and other structural materials.

-

Automotive: Fabricating chassis components, exhaust systems, and body panels.

-

HVAC and Ductwork: Cutting and shaping metal ducts and ventilation systems.

-

Art and Sculpture: Creating intricate metal artwork and sculptures.

-

Demolition: Removing and dismantling metal structures and equipment.

-

Mining and Quarrying: Cutting and shaping metal components for mining machinery.