Buyer Guide

2000w Handheld Laser Cleaner Rust Remover

Laser cleaning technology is a method used to remove contaminants or unwanted material from the surface of an object using laser beams. It is a non-contact and non-abrasive technique that is gaining popularity in various industries for its precision and effectiveness.

Laser cleaning works by emitting a focused laser beam onto the surface of the material. The energy of the laser beam interacts with the rust or other contaminants, causing them to vaporize or ablate. As a result, the rust is removed, leaving behind a clean surface. The process is precise and does not damage the underlying material.

2000w Handheld Laser Cleaner – 2000w Handheld Laser Rust Remover

A 2000W handheld laser cleaner rust remover refers to a portable device that utilizes a high-power laser beam, with a power output of 2000 watts, for the purpose of removing rust and other surface contaminants from various materials. Laser cleaning technology offers a non-contact and precise method for rust removal, providing an alternative to traditional methods like abrasive blasting or chemical cleaning.

Handheld laser cleaners are designed to be portable and easy to maneuver. They typically feature a lightweight design and may include a handheld control unit or ergonomic handle, allowing operators to access and clean various areas with ease.

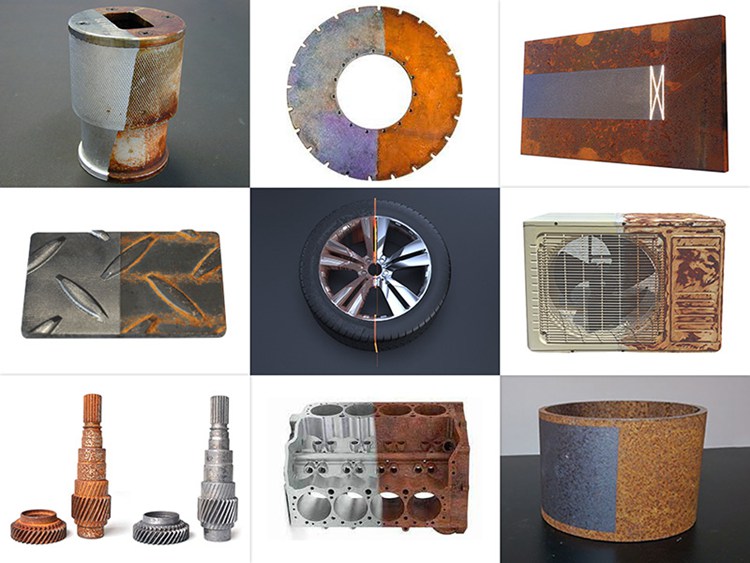

Handheld laser cleaners can be used on a wide range of materials, including metals like steel, iron, aluminum, and copper. They are effective in removing rust, paint, oxide layers, oil, grease, and other contaminants from surfaces. The versatility of handheld laser cleaners makes them suitable for applications in industries such as manufacturing, automotive, aerospace, restoration, and more.

Handheld Laser Cleaner Rust Remover Features

Cleaning Efficiency

Handheld laser cleaners offer high cleaning efficiency by delivering a concentrated laser beam directly onto the rusted surface. The laser energy quickly vaporizes and removes the rust, leaving a clean and restored surface behind. The efficiency of the cleaning process allows for faster turnaround times compared to traditional cleaning methods.

Non-Destructive Cleaning

One of the significant advantages of laser cleaning is its non-destructive nature. The laser selectively removes rust and contaminants without damaging the underlying material. This makes it suitable for delicate or sensitive surfaces, including historical artifacts, machinery parts, and precision components.

Cleaning Parameters

Handheld laser cleaner typically offer adjustable cleaning parameters to optimize the cleaning process for different materials and levels of rust. Parameters such as laser power, pulse duration, repetition rate, and scanning patterns can be adjusted to achieve the desired cleaning results.

Mobility and Flexibility

Handheld laser rust remover are designed to be portable and offer flexibility in cleaning operations. They are suitable for both stationary and on-site cleaning tasks, allowing operators to reach areas that are difficult to access with larger cleaning equipment.

Maintenance and Safety

Handheld laser rust remover require regular maintenance to ensure their optimal performance. This may include cleaning and inspecting the optics, checking the cooling system, and replacing consumable parts as needed. Additionally, laser safety measures, including proper training, use of protective gear, and adherence to safety protocols, should be followed to protect operators and bystanders from laser hazards.

Cost Considerations

Handheld laser cleaner can vary in cost depending on factors such as power output, brand, and additional features. It’s important to evaluate the specific cleaning requirements and consider the long-term cost-effectiveness of laser cleaning compared to traditional methods.

Handheld cleaning laser is promising in the future

At present, laser cleaning applications are sprung up in China. When it comes to future development trends, Mr. Jin expressed his views, “The biggest competitor in the laser cleaning market is not the competition among peers, but laser cleaning and traditional cleaning. The competition of methods. Limited by technology and cost performance, the future laser cleaning will develop from two aspects. On the one hand, it will develop towards high-end, instead of sandblasting machines, and develop towards high power or even ultra-high power to improve the efficiency of laser cleaning; On the one hand, it is developing towards civilians, replacing angle grinders and improving the cost-effectiveness of laser cleaning.”

Application Fields Of Laser Rust Cleaning Machine:

Microelectronic field: semiconductor components, microelectronic devices, memory templates, etc.;

Field of cultural relic’s protection: stone carvings, bronzes, glass, oil paintings and murals;

Abrasive cleaning: rubber mold, composite mold, metal mold, etc.;

Surface treatment: hydrophilic treatment, surface roughening, weld treatment before and after welding, etc;

Paint and rust removal: aircraft, ships, weapons and equipment, bridges, metal pressure vessels, metal pipelines, etc; Aircraft parts, electrical product parts, etc.;

Other: Urban graffiti, printing roller, building exterior wall, nuclear industry, etc.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.