Buyer Guide

CNC Plasma Tube Cutting Machine

The CNC plasma tube cutting machine has become a cornerstone in the metal fabrication industry, offering unparalleled precision, speed, and versatility. This advanced technology allows for intricate cuts and detailed designs on metal tubes, revolutionizing the way metal components are manufactured.

CNC Plasma Tube Cutting Machine

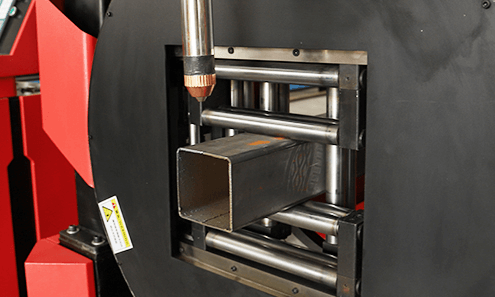

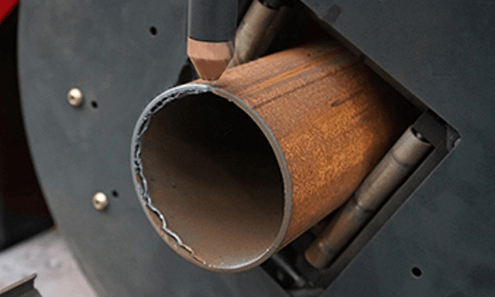

CNC plasma tube cutting machine is used for cutting various types of metal tubes and pipes with precision using a computer numerical control (CNC) system. It employs a plasma cutting torch that can move along multiple axes to make intricate cuts according to programmed designs. These machines are widely used in industries such as construction, automotive, and manufacturing for creating parts and components from metal tubes efficiently and accurately.

Plasma cutting machine is a machine that processes metal materials with the help of plasma cutting technology. Fast cutting speed, small deformation, smooth cutting surface, small thermal deformation, almost no heat affected zone, can be cut square tube, round tube;Standard equipped with two modes of plasma cutting and flame cutting, integrated structure, bilateral drive, fast cutting speed, low inertia and stable operation.

CNC Plasma Tube Cutting Machine Features

- Precision Cutting: Achieves high precision and accuracy in cutting tubes and pipes.

- Versatility: Capable of cutting various materials, including steel, stainless steel, aluminum, and other conductive metals.

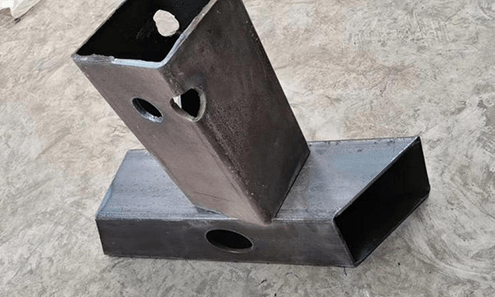

- Complex Cuts: Can perform intricate cuts, including bevels, holes, slots, and notches.

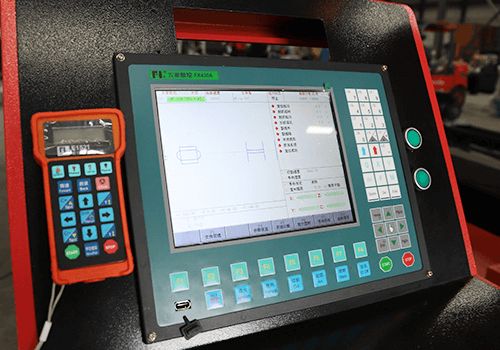

- Automated Operation: Controlled by CNC software, allowing for automated and repeatable cutting processes.

- High Speed: Faster cutting speeds compared to manual methods.

- Consistent Quality: Provides consistent cutting quality with minimal human error.

Plasma Tube Cutting Machine Applications

- Construction: Fabricating structural components for buildings and infrastructure.

- Automotive: Cutting exhaust pipes, roll cages, and other automotive parts.

- Oil and Gas: Manufacturing pipes and fittings for pipelines.

- Shipbuilding: Creating complex piping systems for ships.

- Metal Fabrication: Producing custom metal components for various industries.

Choosing the Right CNC Plasma Tube Cutting Machine

When selecting a CNC plasma tube cutting machine, several factors need to be considered:

Material Compatibility

Ensure that the CNC plasma tube cutting machine is compatible with the types of metal tubes you intend to work with. Different machines are designed to handle specific materials, so choose one that meets your requirements.

Power and Speed

Consider the power and speed of the CNC plasma tube cutting machine. Higher power and speed allow for faster cutting and shaping, making the machine more efficient for large-scale projects.

Software Integration

Look for a CNC plasma tube cutting machine with advanced software integration. This will enable you to customize and control the machine with precision, ensuring that your designs are executed accurately.

Budget

While CNC plasma tube cutting machines can be a significant investment, it’s essential to consider the long-term benefits. Evaluate the cost savings, increased efficiency, and improved quality that the machine will bring to your projects.

Benefits of Using Plasma Tube Cutting Machine

- Tube Handling Capabilities:

- Able to handle a wide range of tube sizes, typically from 1/2 inch to 12 inch diameters.

- Includes motorized clamping and rotation systems to securely hold the tubes during cutting.

- Automatically loads, positions, and unloads the tubes for efficient production.

- Precision Plasma Cutting:

- Uses a high-temperature plasma arc to rapidly and accurately cut through metal tubing.

- Produces clean, consistent cuts with minimal deformation or burrs.

- Advanced CNC controls allow for complex 2D and 3D cutting profiles.

- Automated Reporting:

- CNC controllers with integrated software track and log cutting parameters.

- Provides detailed production data and part traceability.

- Material Compatibility:

- Able to cut a variety of metal tubing materials including steel, stainless steel, aluminum, copper, etc.

- Thickness capacity can range from 16 gauge up to 1/2 inch thick.

Conclusion

A CNC plasma tube cutting machine is an invaluable tool for both professionals and hobbyists in the metal fabrication industry. Its high precision, versatility, and efficiency make it ideal for a wide range of applications. By considering factors such as material compatibility, power and speed, software integration, and budget, you can select the right CNC plasma tube cutting machine for your needs. Proper maintenance and safety measures are essential to ensure the efficient and safe operation of these advanced machines.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.