Laser Knowledge

How Thick Can a Laser Cutter Cut

Optical fiber laser cutting machine works on stainless steel, carbon steel, alloy steel, aluminum plate, copper, titanium, and other metal materials. Depending on the material and thickness of the metal sheet and the laser power, the cutting thickness of the fiber laser cutter is also different. So, how thick can it cut?

Fiber Laser

Fiber lasers are excellent for cutting metals. They have a high energy density and are highly focused. A relatively low – power fiber laser (e.g., 100 – 300 watts) can cut through thin – gauge metals like stainless steel, aluminum, and mild steel up to about 0.1 – 0.2 inches thick.

High – power fiber lasers (e.g., 1 – 4 kilowatts) can handle much thicker metals. They can cut through steel plates up to about 1 – 2 inches thick. Some industrial – grade fiber lasers with extremely high power (over 10 kilowatts) are even capable of cutting steel up to several inches thick, but these are usually used in heavy – duty industrial applications such as shipbuilding.

If it is simply calculated according to the theoretical situation, every time the fiber laser cutting machine increases the power of 100W, it can cut additional sheet metal with a thickness of 1mm. But this is not the case. Let’s take a 1,500W fiber laser cutting machine as an example, it can theoretically cut carbon steel plates up to 16mm thick. However, when the equipment is in operation, the electrical energy is converted into light energy and then converted into heat energy, which will cause a certain amount of energy loss. Therefore, the actual cutting thickness value is not the theoretical value.

According to IGOLDEN professional cutting technology and years of laser cutting experience, I would like to share with you the reference values of different sheet metal thicknesses that can be cut by fiber laser cutting machine at different powers.

*Note: As gas purity, on-site voltage and current, plate type and operator expertise are different, the cutting parameters above are only for your reference.

With the gradual maturity of 12kW+ technology, IGOLDENCNC has launched the star product H series, with a power of 1,500-40,000W to meet different customer needs, and it can cut metal sheets up to 100mm. At the same time, the stress relief annealing technology increases the plasticity and toughness of the machine tool; the super long working format breaks through the limitation of the processing format, thus achieving higher processing efficiency, stronger processing capability, and lower processing cost.

In addition to cutting sheet metal materials, in the actual application process, the cutting ability of the fiber laser cutting machine is also related to various factors such as the quality of the cutting machine, the type of laser source, the cutting environment, the cutting speed, and the auxiliary gas. Therefore, there is no absolute standard to judge its cutting thickness.

1. Focus position

The focus of the laser cutting machine can be aligned, and the cutting accuracy and precision can meet the expected requirements.

2. Cutting speed

In fact, no matter what the material is, the cutting speed can be very consistent with the material, so the cutting effect is the best at this time. Too fast or too slow will affect laser cutting.

3. Working power and mode of laser equipment

It has been proved by research that the higher the power of the laser equipment, the better the effect will be when cutting the same plate. Therefore, the higher the laser power, the thicker the plate can be cut.

4. Auxiliary gas pressure and type

The higher the pressure of the auxiliary gas, the higher the purity of the gas, the fewer impurities attached to the material, and the smoother the cutting edge. Generally speaking, different gases have different cutting effects. Oxygen-cutting speed is the fastest. Nitrogen-cutting has the best effect and low cost.

Pay attention to the above points to improve the cutting quality of the laser cutting machine and ensure that the equipment is in the best state!

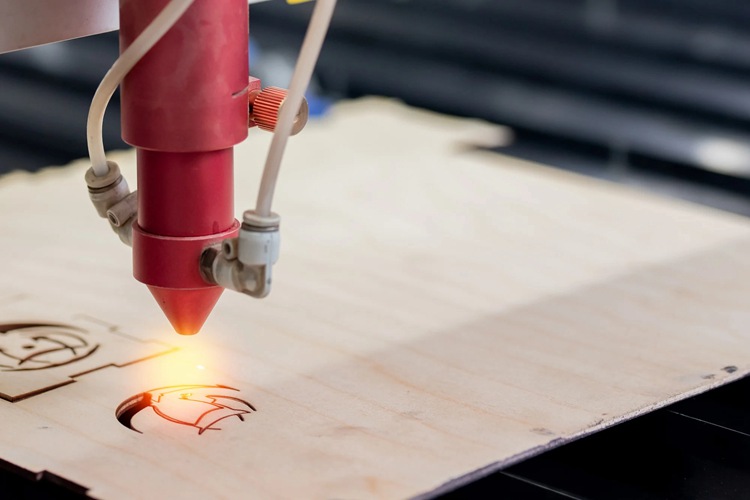

CO₂ Laser

CO₂ lasers are commonly used for cutting a wide range of materials. They can cut through materials like wood, acrylic, and some plastics quite effectively. In the case of non – metallic materials, a CO₂ laser with moderate power (e.g., 40 – 100 watts) can cut materials up to several inches thick. For example, it can cut wood up to about 1 – 2 inches thick, depending on the density of the wood. For acrylic, it might be able to cut up to 0.5 – 1 inch thick sheets.

When it comes to cutting metals, CO₂ lasers are less efficient than fiber lasers. However, they can still be used for thin – metal cutting. A high – power CO₂ laser (e.g., over 1000 watts) might be able to cut through thin – gauge metals such as mild steel up to about 0.2 – 0.3 inches thick.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.