No products in the cart.

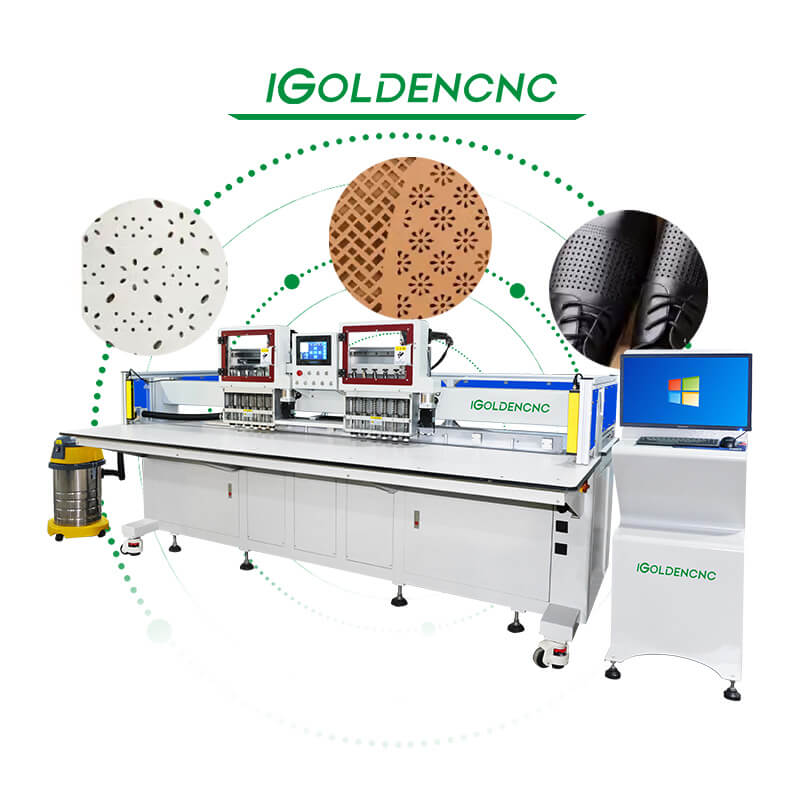

iGK-L6050

Automatic Leather Punching Machine

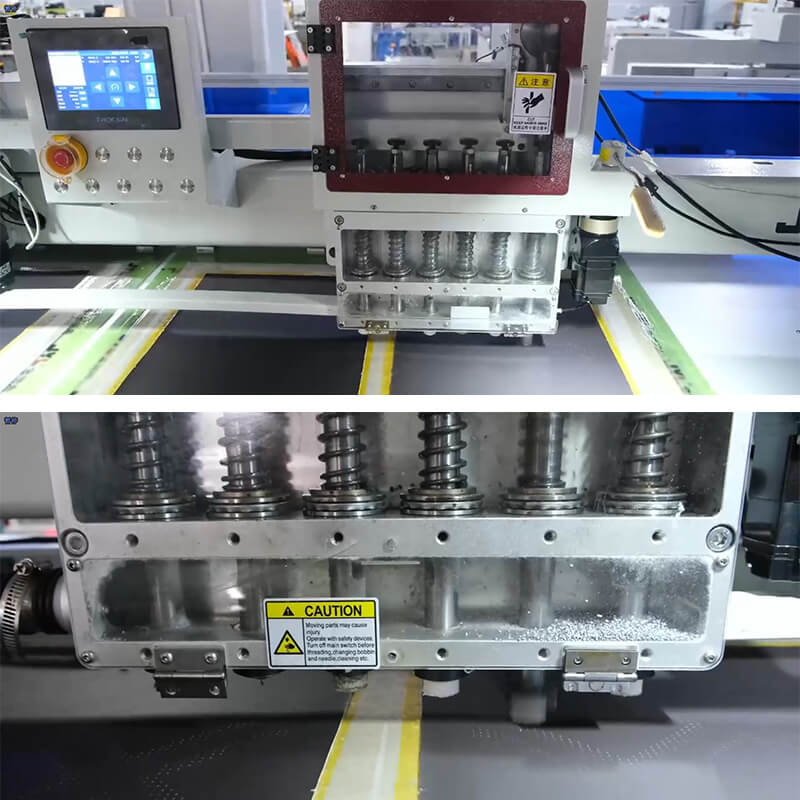

A leather pattern punching machine is a specialized equipment used to cut, punch, or emboss designs into leather or similar materials. These machines are employed in various stages of leather production, from basic hole punching to creating detailed and complex patterns that enhance the aesthetic value of leather products. They can be used to create a range of patterns, including perforations, logos, textures, and intricate designs that are typically seen on high-end leather goods.

Fully automatic leather punching machines represent the cutting edge of technology in the leather industry. These machines can be programmed to execute complex designs with minimal human intervention. Operators can load the leather material into the machine, input the desired pattern or design, and let the machine take care of the rest. The automation process increases speed, reduces the risk of human error, and ensures consistency in production. Fully automatic machines are highly efficient and are most commonly used by large manufacturers who need to produce large quantities of leather goods in a short amount of time.

Reviews

There are no reviews yet.