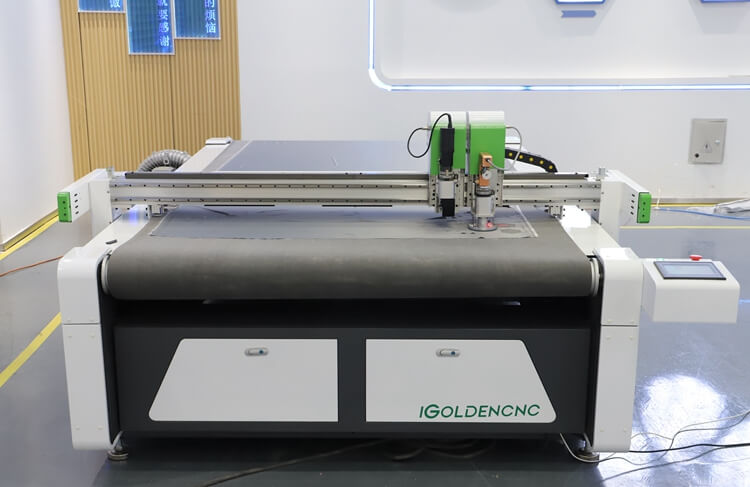

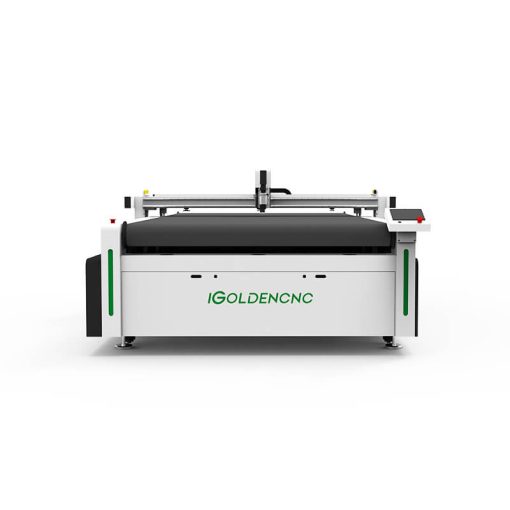

iGK-VA

Digital Die Cutting Machine

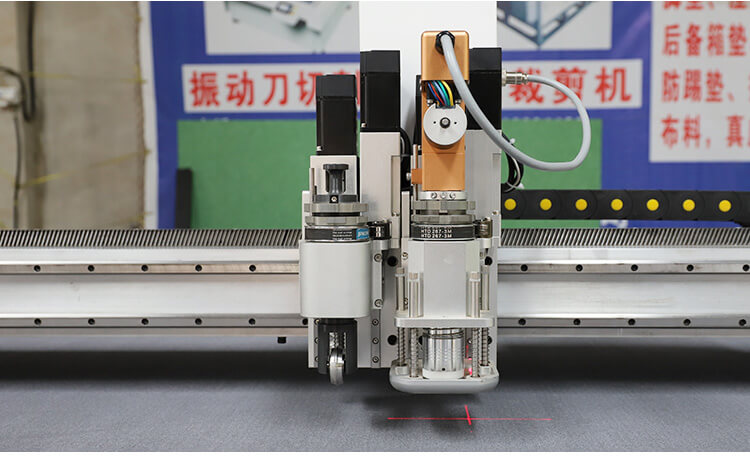

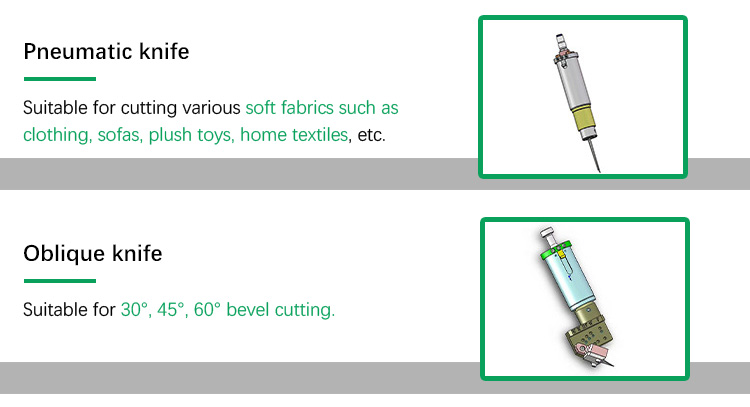

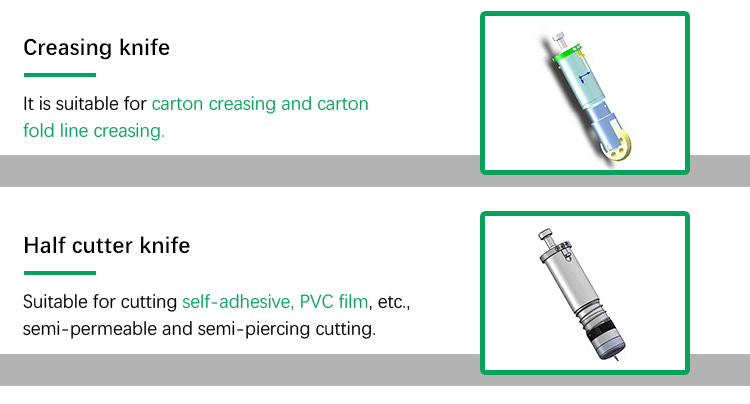

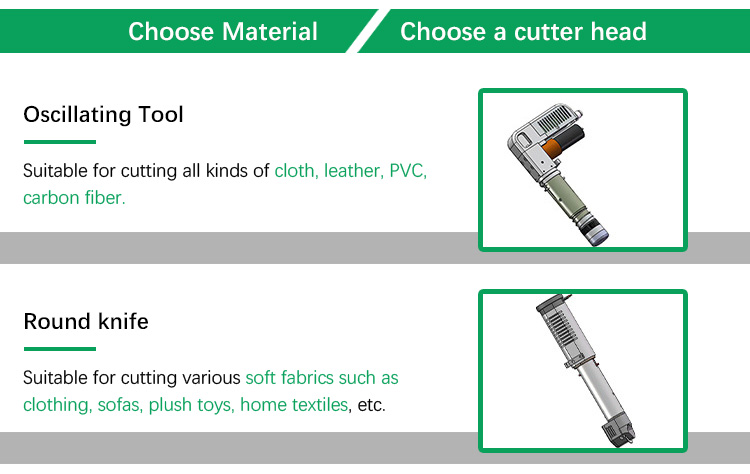

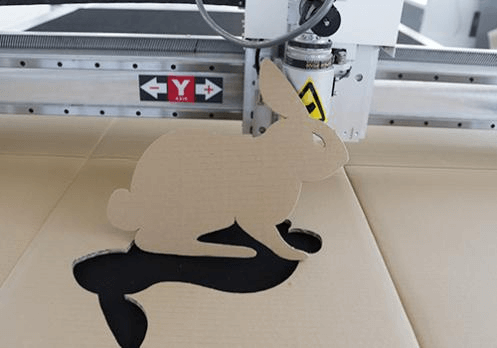

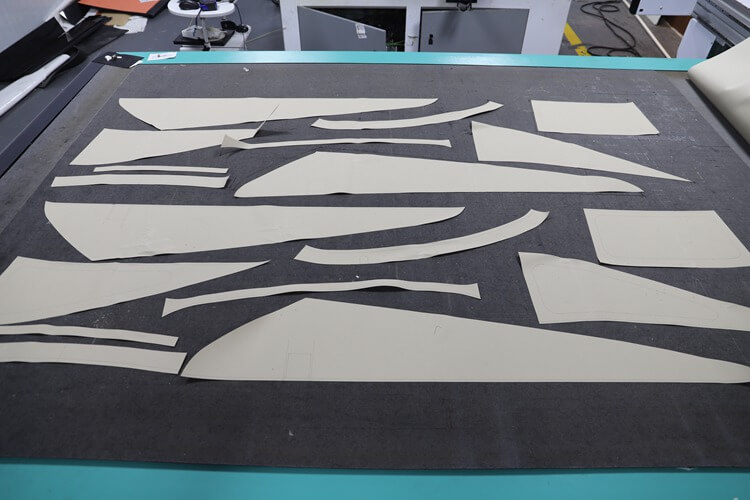

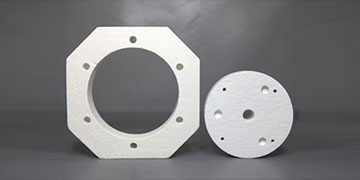

iGK Series high speed flatbed digital cutter is the newly developed cutting system for the industries such as carton packaging, printing, signage graphics, display stands, etc. It has two independent module design to assure the good expansibility and convenient tools exchange. It is equipped with versatile tools like high frequency oscillating knife, creasing tool, V cutting tool, foam cutting tool, drawing tool, drag knife. This flatbed cutter can cut materials up to 60mm. and it is capable with a variety of materials cutting such as corrugated board, card board, grey board, honeycomb board, K board, PP foam board, PE foam, EVA foam, plastic sheet, and other printed sheet.

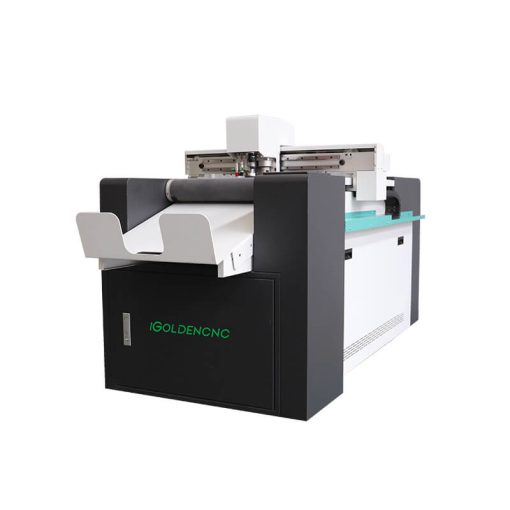

Digital cutting machine with vibrating blades are primarily for cutting special shapes of flexible non-metallic materials, intelligentlyl able to perform processes to end quickly, such as full cutting. Cut it in half. To solve problems, cutting special shapes and improving production efficiency, reducing costs. Reduce job errors By using hand cutters, users can cut a variety of tasks, fast and accurately. Low production costs can compete with the market.

Reviews

There are no reviews yet.