Buyer Guide

Industrial Laser Rust Removal & Cleaning Machine

The industrial sector is constantly evolving, and advanced technology and techniques are needed to replace and fill in the gaps. Surface treatment is an essential part of modern industrial manufacturing, and the demand for surface treatment has increased significantly in recent years. The use of industrial laser rust removal has become a highly sought-after technology in the industrial sector.

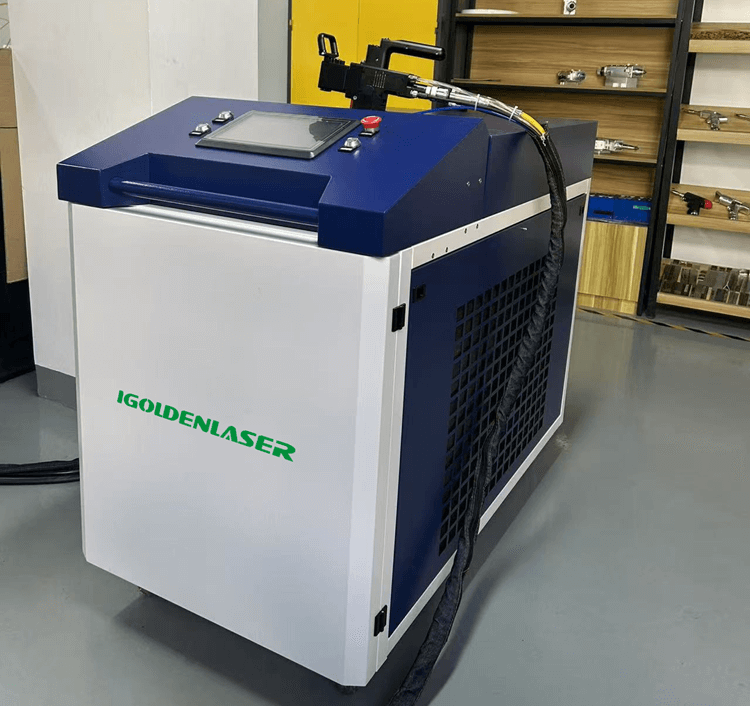

Industrial Laser Rust Removal & Cleaning Machine

An industrial laser rust removal and cleaning machine utilizes high-powered lasers to effectively eliminate rust, corrosion, and contaminants from metal surfaces.

Industrial laser cleaning is a cleaning solution that utilizes high-frequency short-pulse lasers as the working medium. The high-energy beam of specific wavelength is absorbed by the rust layer, paint layer, and pollution layer, forming a rapidly expanding plasma and generating a shock wave that makes pollutants into fragments and removes them. The laser cleaning process doesn’t require the use of any chemicals or cleaning fluids. The waste materials cleaned are mostly solid powders, small in size, and easy to store, making them recyclable through adsorption. There is no photochemical reaction, no noise, and no environmental pollution. It is also safe for the operator’s health and can be easily automated, making it one of the safest and most environmentally friendly solutions for surface cleaning.

Industrial laser cleaning products achieve full power coverage, with different power laser cleaning machines available for different scenarios. Finergy’s laser cleaning solutions cover laser cleaning and surface laser pretreatment of metal surfaces in various industries, such as the mold industry, automobile industry, rail transit industry, electronics industry, manufacturing industry, medical equipment, etc. This provides customers with a complete set of laser cleaning solutions and related supporting facilities.

The penetration rate of industrial laser cleaning is increasing year by year, making it an ideal choice for a new generation of industrial cleaning technology. Fetera’s laser cleaning machine has been well received by customers since its launch and has become the best choice to replace traditional cleaning in industrial cleaning. With continuous improvement and upgrading of laser cleaning machines, it is believed that laser cleaning technology will eventually become accessible to individuals and families, bringing real convenience to daily life.

Laser Light Rust Remover Technical Parameter

| Name | Intelligent Handheld Cleaning Head |

| Model | FWH60-C30A |

| Fiber interface | QBH |

| Wavelength scope | 1070±20nm |

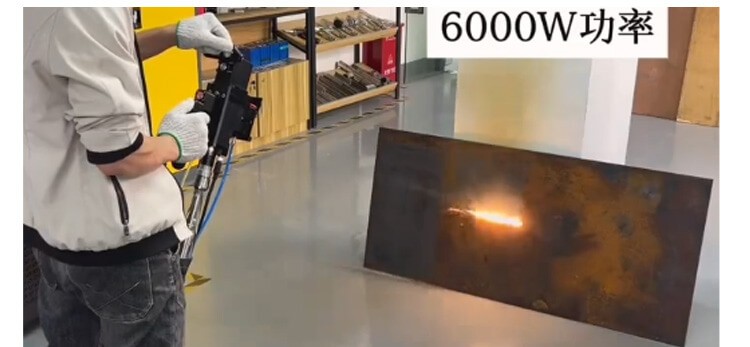

| Rated power | ≤6KW |

| Collimation focal length | 75mm |

| Focus focal length | 1500mm |

| Scanning width | 200~500mm |

| Scanning speed | 40000mm/s |

| Auxiliary pressure | ≥0.5~0.8Mpa |

| Effective clear aperture | Ø20 |

| Weight | 2.2Kg |

Compared with Pulse Type Laser Cleaning Machine, Continuous Fiber Laser Cleaner is More Suitable for Applications Where High Efficiency is Required.

Features

Laser cleaning machines have advantages that traditional cleaning methods lack. For example, they are compact, easy to carry, and can be used for non-contact cleaning without damaging the part matrix. They also provide fine cleaning and can achieve selective cleaning of precise positions and sizes. The machines are easy to operate, can be hand-held or used with a robot for automatic cleaning, and offer high cleaning efficiency, saving time. Industrial laser cleaning systems are stable and reliable.

- Laser Technology: Uses focused laser beams to vaporize rust and contaminants without damaging the underlying material.

- Precision: Capable of targeting specific areas with high accuracy.

- Environmentally Friendly: Reduces the need for harsh chemicals and produces minimal waste.

- Versatility: Suitable for various materials, including steel, aluminum, and other metals.

- Automated Systems: Often equipped with robotic arms for automated cleaning processes.

How Does Laser Rust Removal Work?

The process relies on laser ablation, where the laser energy is absorbed by the contaminant layer, causing it to vaporize or disintegrate instantly.

Key steps include:

- The laser beam targets the rust or coating

- The contaminant absorbs the energy and heats up rapidly

- The material is ejected as a plasma plume or dust

- The clean substrate remains intact underneath

Depending on the material and contamination, different wavelengths, pulse durations, and power settings are used for optimal results.

Types of Industrial Laser Cleaning Machines

1. Continuous Wave (CW) Laser Cleaners

- Emit a constant laser beam

- Ideal for large-area cleaning and thick coatings

- High-speed processing

2. Pulsed Fiber Laser Cleaners

- Emit laser pulses at high peak power

- Perfect for delicate surfaces and precision cleaning

- Minimal heat input reduces risk of substrate damage

3. Handheld Laser Cleaners

- Portable and flexible

- Suitable for on-site maintenance and hard-to-reach areas

4. Automated Laser Cleaning Systems

- Integrated with robotic arms or CNC gantries

- Best for high-volume industrial applications

Conclusion

The Industrial Laser Rust Removal & Cleaning Machine represents a monumental leap forward in surface preparation and restoration. By offering eco-friendly, non-destructive, and highly precise cleaning, it outperforms traditional methods in virtually every metric.

Whether you’re maintaining heavy machinery, restoring classic cars, or preparing aerospace components, investing in laser cleaning technology can boost efficiency, reduce costs, and enhance quality.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.