No products in the cart.

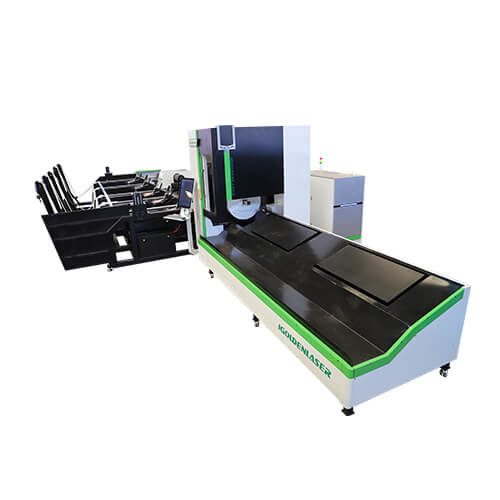

iGR-T8022

Fiber Laser Pipe Cutting Machine

iGR-T series pipe fiber laser cutting machine is a kind of laser cutting equipment, designed for cutting various types of metal pipes with high precision and high speed, optional automatic feeding device, save labor, improve efficiency, tail blind area is small, save materials, using pneumatic chuck + follow support, efficient and stable, double insurance.

The cutting machine feeding equipment is a laser pipe cutting machine feeding equipment and laser pipe cutting machine integrated system, mainly to achieve a centralized storage of a kind of pipe, instead of manual automatic feeding for laser pipe cutting machine, can achieve small batch, multi-variety production needs.

Suitable for a variety of pipe cutting, can cut round pipe, square pipe, rectangular pipe, hexagonal pipe, D-shaped pipe, other special-shaped pipe.

Widely used in auto parts, kitchen hardware, electronics, electrical, smart home and many other industries.

Marcin Dudek –

IGOLDENLASER’s after-sales engineers are so professional, whether they are in China at night or on vacation, they can respond to and solve problems in a timely manner, thank you very much.