IGL-C1390

Co2 Laser Engraving and Cutting Machine

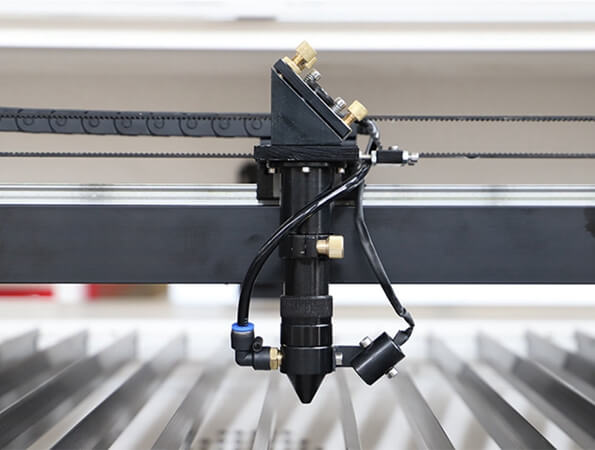

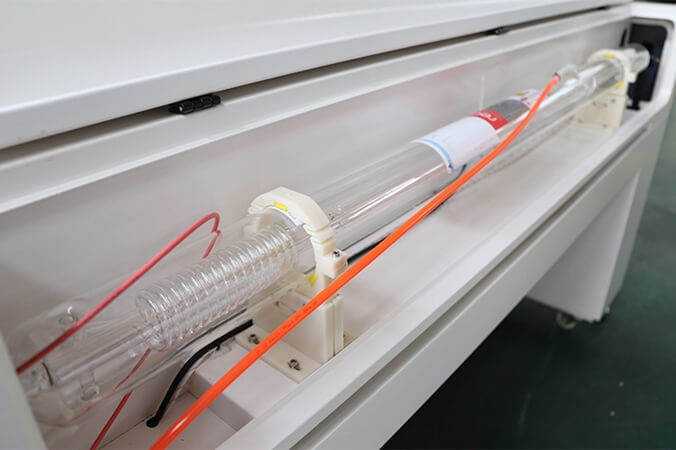

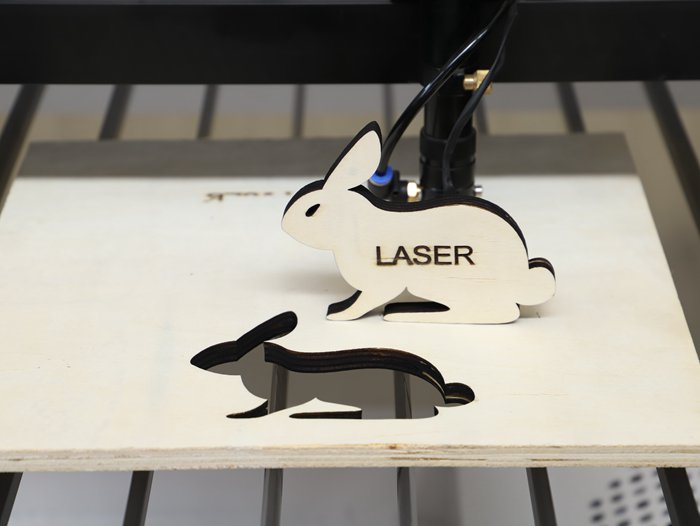

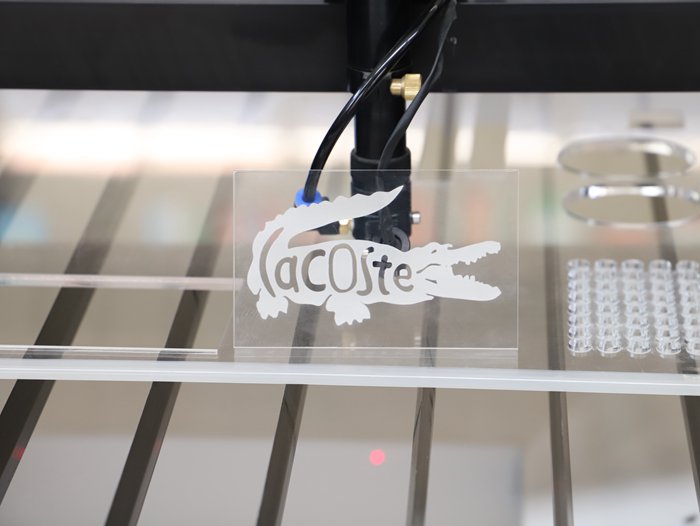

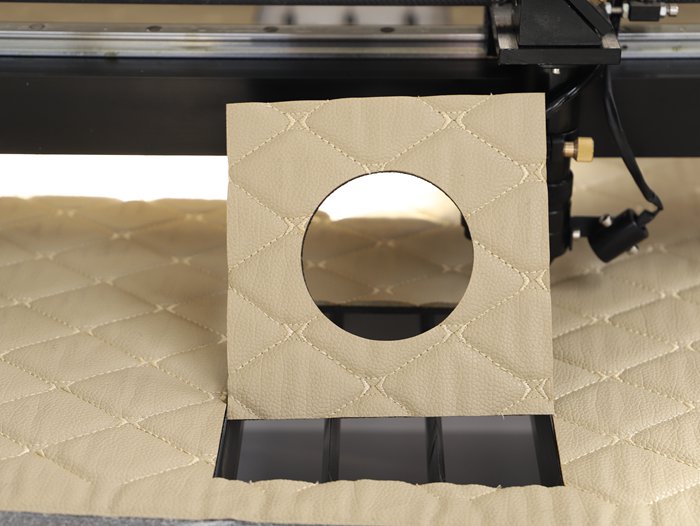

A CO2 laser cutting machine is a professional automatic engraving and cutting system using a 1064μm CO2 laser beam to etch and cut wood, MDF, plywood, paper, leather, fabric, textile, resin, plastic, acrylic, rubber, crystal, glass, ceramics, stone, and more non-metallic materials. It relies on the power to drive the carbon dioxide gas laser tube to emit beam, with reflectors, the beam is transmitted to the cutting head, and then the focusing mirror converges the beam on a point, and this point can reach a very high temperature, thus the excess material is instantly sublimated into gas, which is sucked away by the exhaust fan, so as to create a cut. It is used to engrave and cut in clothing, fashion, garment, shoes, bags, toys, embroidery, electronic appliances, molds, models, arts, crafts, advertising, decorations, packaging, and printing.

Carbon dioxide laser is a gas molecular laser, the working substance is CO2 gas, auxiliary gases are nitrogen helium, xenon and hydrogen, etc., because the energy conversion efficiency of this laser is as high as 25%, it is often a high-power output laser, carbon dioxide laser wavelength 10.6 microns, is impossible to see infrared light, good stability, widely used.

Greg –

This is a special 3D laser engraver and you should buy for personalized crystal souvenirs and gifts for your custom business. The subsurface engraving details in crystal are amazing. It’s pricey but it was worth every penny. It paid for itself in less than three months.