Buyer Guide

Acrylic Laser Cutter | Laser Engraving Acrylic

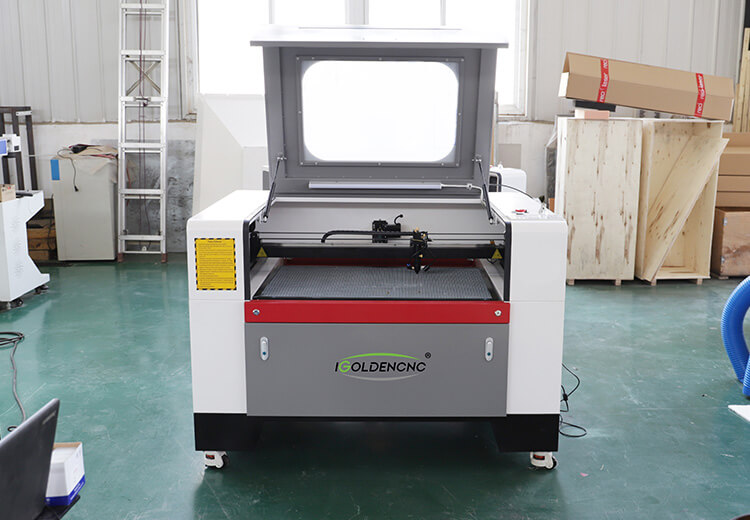

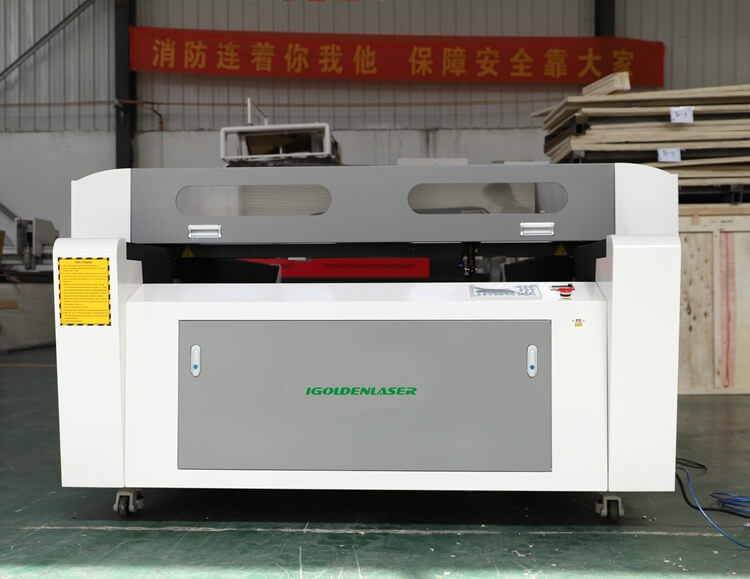

An acrylic laser cutter is a cutting-edge technological tool designed for precision cutting and engraving of acrylic materials. This advanced equipment utilizes laser technology to achieve unparalleled accuracy and intricacy in shaping acrylic sheets.

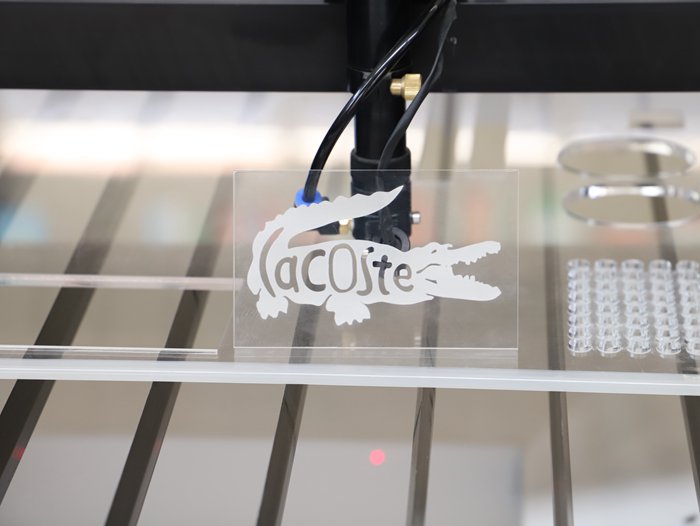

Laser cutter machines are used to cut plastics, clear and colored acrylic sheets to produce various parts such as patterns, signs, logos, letters, numbers, and arts and crafts. It provides a very precise process with an extremely narrow notch width for complex contours. Manpower can be reduced by the full automation and minimal human involvement of laser cutting devices. It is easy to operate thanks to its advanced control system, intelligent software, and assembly. It has a simple and precise working position.

IGOLDENlaser team can design various types of laser machines depending on working size, laser tube watts required, etc. We can recommend the best acrylic cutting machine for your company. Message us today.

Acrylic Suitable for Laser Technology

The types of acrylic ideal for laser cutting are the following:

Cast acrylic sheets are fabricated by pouring liquid acrylic into molds. It can be configured into different shapes and sizes. This can be laser cut and engraved.

Extruded acrylic sheets can be cut cleanly and smoothly. It can be a flame-polished edge when laser cut. Extruded acrylic is a very popular cutting material.

No matter what the acrylic types, we can provide an accurate laser cutting machine with automated and intelligent functions.

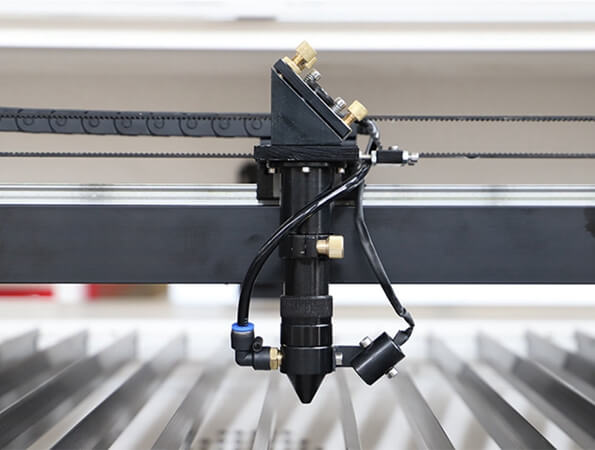

Acrylic Laser Cutter Working Principles

Acrylic laser cutters operate on the principles of laser technology, harnessing the power of focused laser beams to cut through acrylic sheets with high precision. The process involves emitting a laser beam from a laser tube, which is then directed through mirrors and lenses to focus on the acrylic surface. The intense heat generated by the concentrated laser beam vaporizes or melts the acrylic material along the cutting path, leaving behind a clean and precise cut. The level of precision achievable with acrylic laser cutters makes them indispensable in various industries.

Why Choose IGOLDEN Acrylic Laser Cutter Machine

Offers Unique Shape

An acrylic laser cutter can cut various shapes and patterns suitable for your projects. Depending on the wattage of the laser cutter, it can cut different acrylic thicknesses.

High Speed

Acrylic laser cutter can cut and engrave well at a high speed and low power. Guaranteed high efficiency, high productivity, and offer extreme precision and consistency.

Sturdy and Durable

All machines are made from sturdy and durable components and materials. Thus, it can operate well 24 hours, and shorten your production lead time.

Customizable

We design superior quality machines according to your unique specifications and requirements. We can etch the logo of your brand to market your business.

Thin Acrylic Laser Cutting Machine

- 80W, 100W, 130W, and 150W laser tubes are recommended for less than 10mm thin acrylic fast and productive cutting. The bigger power, the faster speed.

- Safe, efficient, and precise operation

- Maximum reliability, performance, speed, and quality end product.

Thick Acrylic Laser Cutting Machine

- High power 150W and 200W laser tubes are recommended for 24/7 materials processing thick acrylic up to 20mm.

- No after-polishing process needed

- High definition processing with the excellent edge quality

- Easy to use and super low maintenance.

Acrylic Laser Cutting and Engraving Machine

- One laser machine with multi-functions including cutting and engraving.

- Better with smaller power laser tubes to perform with thinner spot size and achieve a better engraving effect

- Works on both cast and extruded acrylics

- Engrave well at a high speed and low power

Acrylic Laser Cutting and Engraving Machine Applications:

- Signage and Display Industry: Acrylic laser cutters are extensively used in the signage and display industry for creating intricate lettering, logos, and decorative elements. The ability to achieve fine details and smooth edges makes acrylic laser cutting a preferred choice for producing visually appealing signs and displays.

- Art and Craft: Artists and craftsmen leverage acrylic laser cutters to bring their creative visions to life. The precision and versatility of these cutters allow for the creation of detailed artworks, sculptures, and personalized crafts from acrylic materials.

- Industrial Prototyping: In industrial settings, acrylic laser cutting is employed for rapid prototyping and model development. The ability to produce accurate and intricate prototypes enables manufacturers to assess designs before mass production, saving time and resources.

- Architectural Model Making: Architectural firms utilize acrylic laser cutters to fabricate detailed architectural models. The precision and speed of laser cutting contribute to the creation of intricate scaled models that are crucial for visualizing and presenting architectural concepts.

Laser Cutting Speeds

When cutting acrylic, 80W to 200W glass Co2 laser tubes are recommended. Bigger power laser tubes like 200W are highly suggested for cutting thick acrylic materials up to 20mm thickness. Generally speaking, for the same thickness acrylic, the bigger power, the cutting speed would be faster.

IGOLDEN supplies high-performance laser technology that can work on the cast and extruded acrylics. It can provide precise patterns, textures, and hues. IGOLDEN provides exact parameters and other technical features to ensure that they match your needs.

how an acrylic laser cutter typically works:

- Design: You start by creating a design or preparing a digital file that specifies the shape and details you want to cut or engrave on the acrylic material. This file is usually created using computer-aided design (CAD) software.

- Setup: You place the acrylic material onto the cutting bed of the laser cutter. The cutting bed is typically a flat surface that can be adjusted to accommodate different sizes and thicknesses of acrylic.

- Configuration: You configure the laser cutter settings according to the type and thickness of the acrylic material you’re working with. This includes determining the laser power, cutting speed, and focus.

- Calibration: Before cutting or engraving, you may need to calibrate the laser cutter to ensure precise alignment and focus of the laser beam. This is usually done using a calibration procedure provided by the manufacturer.

- Cutting and engraving: Once the laser cutter is set up and calibrated, you can start the cutting or engraving process. The laser beam follows the paths specified in the digital file, cutting through the acrylic material or engraving its surface. The laser can create intricate and detailed designs with high precision.

- Finishing: After the cutting or engraving is complete, you may need to remove the acrylic piece from the cutting bed and perform any necessary post-processing, such as removing protective film, cleaning the edges, or applying additional treatments or finishes.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.