No products in the cart.

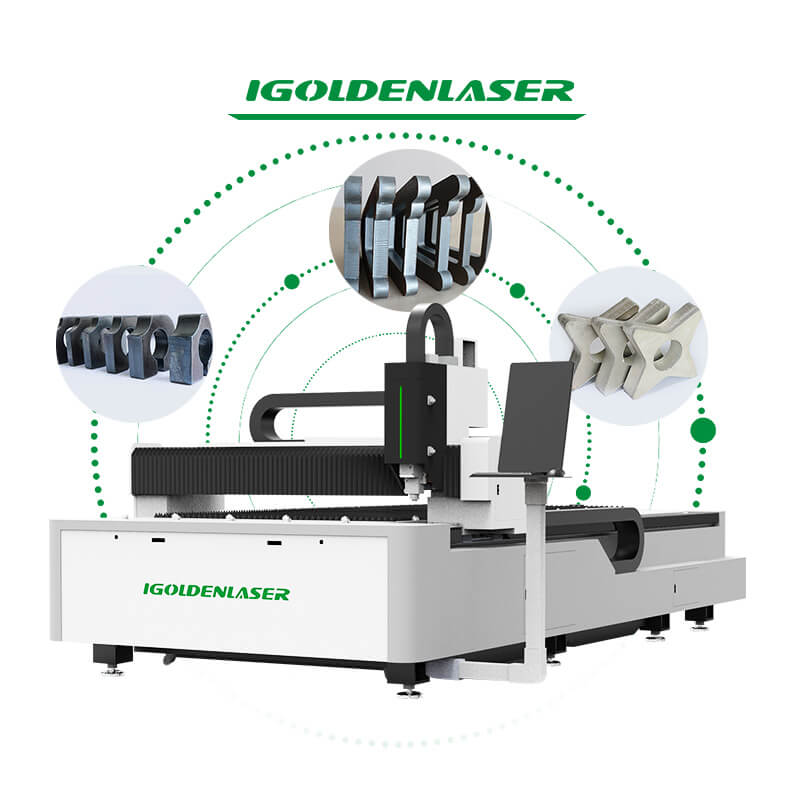

CNC Fiber Laser Cutting Machine

iGR-FH series laser cutting machine is the new generation of safe, high efficiency, energy saving, laser cutting equipment, using heavy-duty welding bed, aviation aluminum beam, equipped with high-efficiency transmission system such as imported high-precision double-drive rack and pinion and linear guide, combined with the advanced CYPCUT control system, the precision CNC fiber laser cutting machine is assembled.

Hot application is: Machinery industry、Manufacturing industry、Advertising industry、Processing industry、Precision industry.

The maximum power of the machine can reach 12000W, the dynamic performance of the equipment is good, the servo response is fast, the slit is small, and the thermal effect is small. It is a good choice.

William –

This metal laser cutting machine is a powerhouse in our workshop. It cuts through various metals with incredible precision and speed.

Charles –

The level of detail and accuracy we can achieve with this laser cutter is remarkable. It has drastically improved the quality of our products.