Laser Knowledge

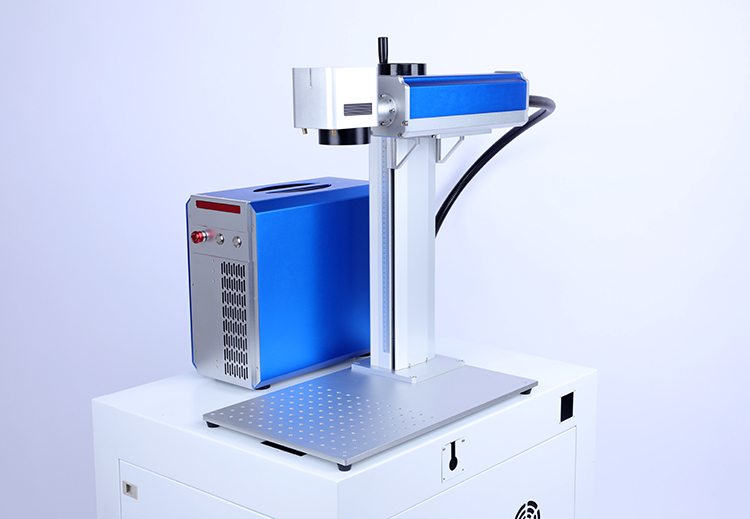

Affordable Mopa Fiber Laser Engraver for Sale

MOPA (Master Oscillator Power Amplifier) fiber laser engravers are advanced laser systems that use a master oscillator to generate the laser beam and a power amplifier to boost its power. This configuration allows for precise control over the laser’s pulse duration, frequency, and power, making it ideal for a wide range of materials and applications.

The application scenarios of MOPA laser marking machine include but are not limited to the following aspects:

Applications of MOPA Fiber Laser Engravers

MOPA fiber laser engravers are used in a wide range of applications across various industries. Some of the most common applications include:

- Metal Engraving: MOPA fiber lasers are ideal for engraving metals, such as stainless steel, aluminum, and titanium, making them popular in the automotive and aerospace industries.

- Plastic Marking: The adjustable pulse duration of MOPA lasers allows for precise marking on plastics, making them suitable for electronics and consumer goods.

- Jewelry Design: MOPA fiber lasers are used to create intricate designs and patterns on jewelry, enhancing their aesthetic appeal.

- Medical Device Manufacturing: The precision and accuracy of MOPA lasers make them ideal for engraving medical devices and instruments, ensuring compliance with industry standards.

- Art and Craft: Artists and craftsmen use MOPA fiber lasers to create detailed engravings on various materials, adding a unique touch to their creations.

What is a MOPA Laser?

The mopa fiber laser marker has a powerful system that can adjust pulse duration and has great accuracy. It is perfect for marking on different materials, especially metals, with high resolution.

This system is used in many different areas like electronics, medical device labels, jewelry making, and aerospace. It is known for being very accurate and is considered the best in the industry.

This system is used in various fields such as electronics, medical device labels, jewelry making, and aerospace. It is highly accurate and widely regarded as the best in the industry.

The mopa fiber laser engravers utilize Q-switching technology to create unique markings on metals. For example, it can produce black markings on anodized aluminum and colored markings on stainless steel. These mopa laser engraver system integrate seamlessly with software such as AutoCAD and Photoshop to ensure efficiency and fast results.

Why Choose a MOPA Laser Marking Machine? Unveiling Its Superior Advantages Over Other Engraving Solutions.

MOPA fiber laser color markers are exceptional in laser marking, with unique features and abilities that set them apart.

Material Versatility: These markers can engrave various materials such as gold, silver, stainless steel, and different types of plastic. MOPA’s advanced fibre laser technology guarantees accuracy on different materials, including nickel plating.

Adjustable Pulse Duration: MOPA fiber lasers can engrave safely on delicate materials by controlling the pulse shape. Users can adjust the depth and finish, leading to better marking outcomes.

Superior colour marking: MOPA lasers create better engravings on metals and plastics than Q-switched lasers. They can make stainless steel colorful and anodized aluminum very black, which regular lasers cannot do.

Delicate Engraving on Metals: High-tech laser engraver can create detailed designs on thin metals, showcasing their expertise in intricate patterns.

High Speed: Mopa lasers quickly mark items in industries. They have a fast laser head that can go up to 8000 mm/sec.This allows for efficient performance.

Long Life: MOPA laser markers are tough and easy to take care of. Usually, the main parts of MOPA lasers can last for 100,000 hours. Moreover, JPTmopa m7 fiber lasersare generally air-cooled and require no ongoing maintenance.

Quality engraving results:MOPA fiber lasers are renowned for their unparalleled precision and heightened reliability compared to previous laser technologies. Their distinctive ability to minimize heat diffusion ensures the quality and smoothness of engravings, preventing overburn. This sets them apart from other lasers, which can emit excessive heat and create bad marking results.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.