Buyer Guide

Aluminum Laser Cutting Machine for Sale

Aluminum is a widely used material in various industries due to its lightweight, durability, and excellent thermal and electrical conductivity. When it comes to cutting aluminum, traditional methods such as sawing or shearing can be time-consuming and may result in rough edges or material distortion. However, with the advent of laser cutting technology, cutting aluminum has become more precise, efficient, and versatile. In this article, we will explore the benefits and applications of laser cutting machines for aluminum, highlighting their capabilities, advantages, and how they have revolutionized the manufacturing process. So, let’s dive in!

Laser Cutting Machine Aluminum

The “best” laser depends on your specific needs and budget. Generally:

- CO2 lasers: Ideal for thinner aluminum sheets (up to 1/4″) and offer good cutting speeds at competitive prices.

- Fiber lasers: Excellent for thicker aluminum (up to 1 inch) and offer superior edge quality and cutting speeds, but come at a higher cost.

Using a laser cutting machine to cut aluminum is a common practice in various industries due to the precision and efficiency it offers. Aluminum is a highly reflective material, so it requires a laser with sufficient power and appropriate wavelength to cut through it effectively. Typically, fiber lasers are preferred for cutting aluminum because they can effectively penetrate its reflective surface.

The laser cut aluminum plate depends on the power of the laser generator. The thickness of 6000W can be cut to 16mm, and the thickness of 4500W can be cut to 12mm, but the processing cost is high. Because it is a highly reflective material, laser cutting uses a focused high-power-density laser beam. The workpiece, the irradiated material quickly melts, vaporizes, ablates, or reaches the ignition point, and at the same time blows away the molten material by the high-speed airflow coaxial with the beam, to realize the cutting of the workpiece.

Advantages of Laser Cutting Machines for Aluminum

Precision and Accuracy

Laser cutting machines offer exceptional precision and accuracy when cutting aluminum. The laser beam is focused to a small spot size, allowing for intricate and detailed cuts with minimal material waste. This level of precision is crucial, especially in industries where tight tolerances are required, such as aerospace, automotive, and electronics.

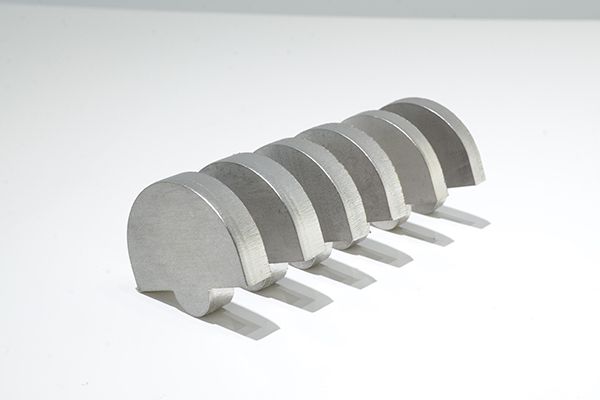

Smooth and Clean Cuts

Unlike traditional cutting methods, laser cutting machines produce smooth and clean cuts on aluminum. The high-energy laser beam melts and vaporizes the material, resulting in a narrow kerf width and minimal heat-affected zone. This eliminates the need for secondary finishing processes, such as deburring or sanding, saving time and reducing production costs.

Versatility in Cutting Thickness

Laser cutting machines for aluminum offer versatility in cutting thickness. Whether you need to cut thin aluminum sheets or thick aluminum plates, laser technology can handle a wide range of material thicknesses. This flexibility allows manufacturers to produce various components and parts with different thickness requirements, all on a single machine.

Complex Shape Cutting

One of the significant advantages of laser cutting machines is their ability to cut complex shapes and contours on aluminum. The laser beam follows a programmed path, allowing for intricate designs and patterns that would be challenging to achieve with traditional cutting methods. This opens up new possibilities for designers and engineers, enabling them to create unique and innovative aluminum products.

High Production Speed

Laser cutting machines are known for their high production speed. The laser beam can cut through aluminum at a rapid pace, significantly reducing cycle times and increasing overall productivity. This is particularly beneficial for industries with high-volume production requirements, where time is of the essence.

Minimal Material Waste

Efficiency is a key consideration in manufacturing, and laser cutting machines excel in minimizing material waste. The precise nature of laser cutting allows for optimal nesting of parts on the aluminum sheet, maximizing material utilization and reducing scrap. This not only saves costs but also contributes to a more sustainable and environmentally friendly manufacturing process.

Applications of Laser Cutting Machine Aluminum

1. Aerospace Industry

In the aerospace industry, precision and lightweight components are crucial. Laser cutting machines are widely used to cut aluminum sheets and plates for aircraft parts, such as fuselage panels, wing components, and engine parts. The ability to cut complex shapes and contours with high precision makes laser cutting an ideal choice for aerospace manufacturers.

2. Automotive Industry

The automotive industry relies on laser cutting machines for aluminum to produce various components, including body panels, chassis parts, and interior trim. Laser cutting ensures precise and consistent cuts, contributing to the overall quality and durability of the vehicles. Additionally, the high production speed of laser cutting machines aligns with the automotive industry’s demand for efficient manufacturing processes.

3. Electronics Industry

In the electronics industry, laser cutting machines play a vital role in producing aluminum enclosures and heat sinks for electronic devices. The ability to cut intricate designs and patterns allows for efficient heat dissipation and optimal component placement. Laser cutting also ensures precise cutouts for connectors, buttons, and display panels, contributing to the sleek and modern aesthetics of electronic devices.

4. Architectural and Design Applications

Laser cutting machines have found their place in architectural and design applications, where aluminum is often used for decorative elements, signage, and façade cladding. The versatility of laser cutting allows designers to create intricate patterns and designs on aluminum panels, adding a touch of elegance and uniqueness to architectural projects.

5. Industrial Manufacturing

Laser cutting machines are widely used in various industrial manufacturing processes that involve aluminum, such as fabrication, prototyping, and production of machinery and equipment. The precision, speed, and versatility of laser cutting make it an essential tool for manufacturers looking to optimize their production processes and meet the demands of a competitive market.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.