No products in the cart.

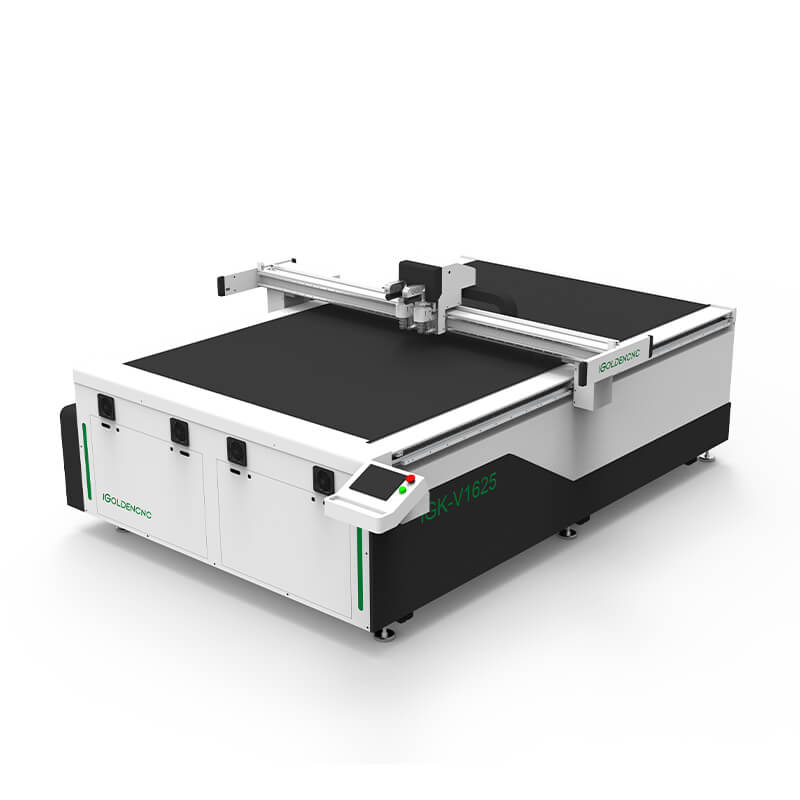

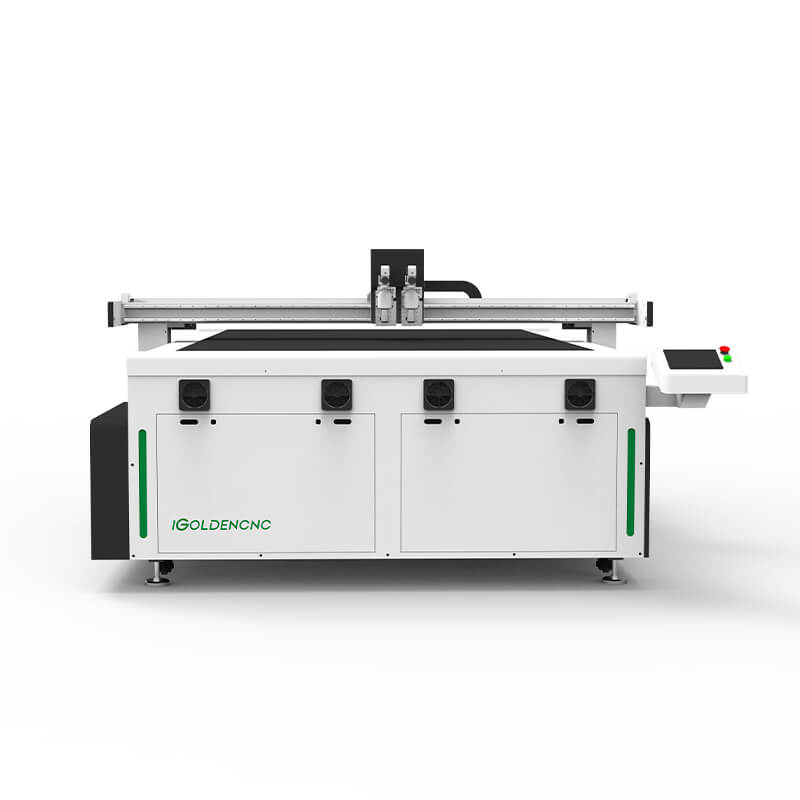

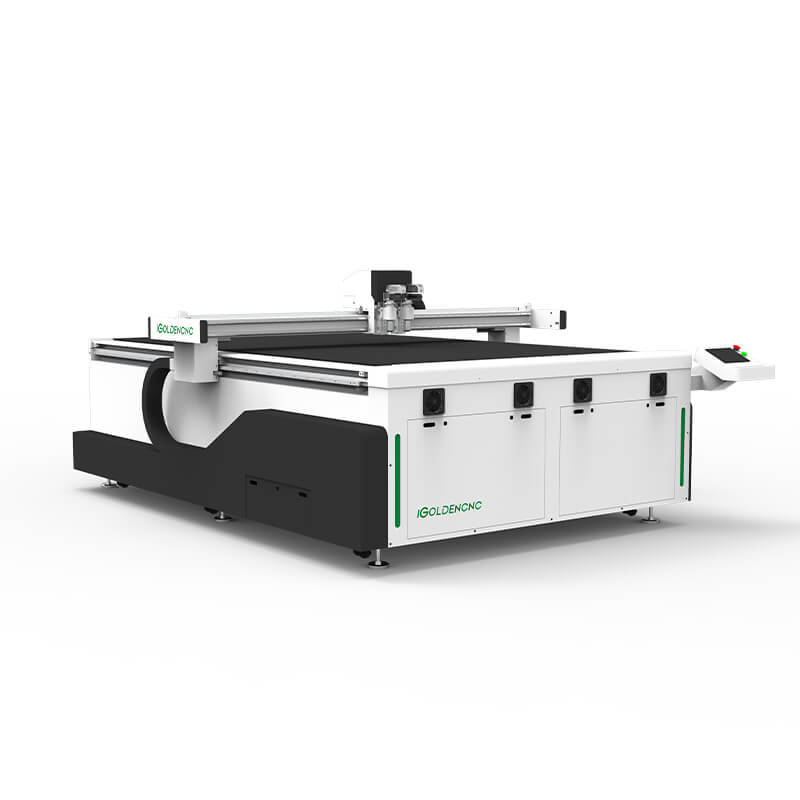

iGK-V

Auto Cardboard Paper Box Die Cutting Machine

With the rapid development of the printing and packaging industry, the demand for high-quality, high-efficiency and diversified cutting processing has been increasing. With the advantages of high automation, high precision and high efficiency, cutting machines are playing an increasingly important role in the printing and packaging industry.

It has functions such as milling, vibration full-cut/half-cut cutting, and drawing. It can not only easily cope with various flexible materials, such as corrugated paper, honeycomb board, cardboard, foam, gray board, KT board, Chevron board, etc., but also can cut and mill hard plastics, acrylic, PVC and other advertising display materials. It is widely used in the cutting, proofing and small-batch production of materials in the packaging, printing, advertising, display and other industries.

Reviews

There are no reviews yet.