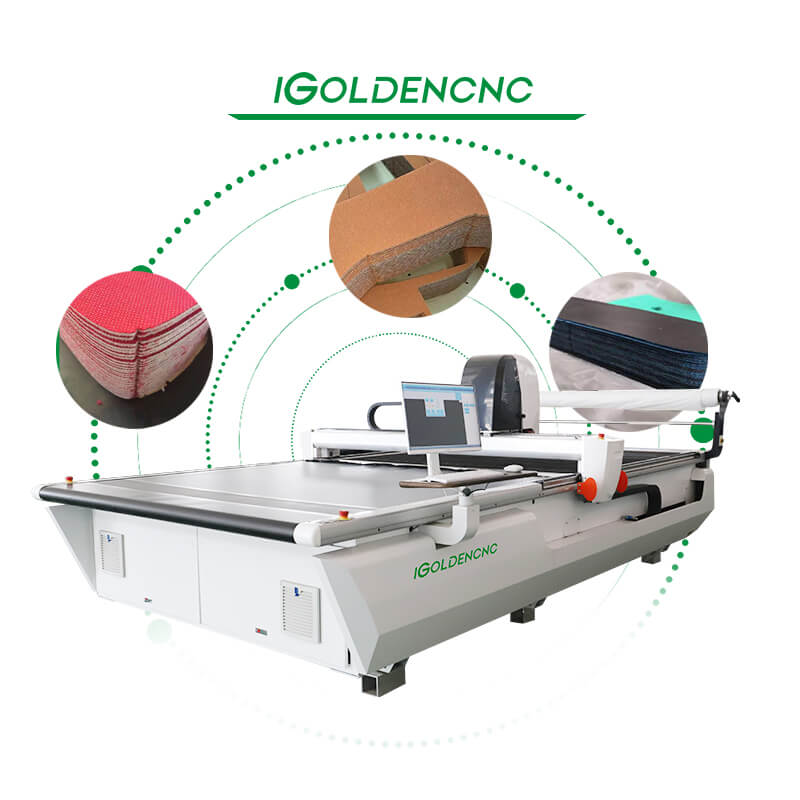

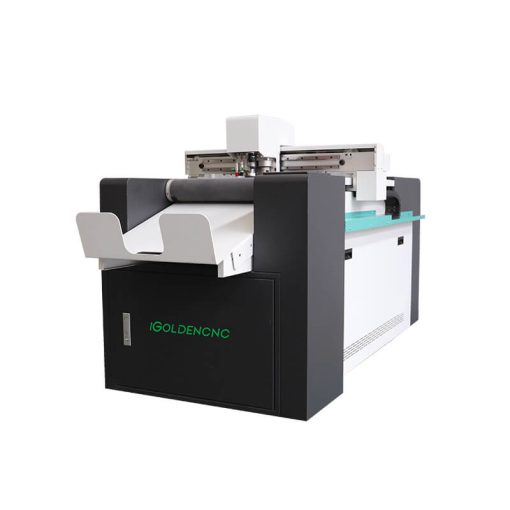

iGK-AC

Multi Layer Fabric Cutting Machine

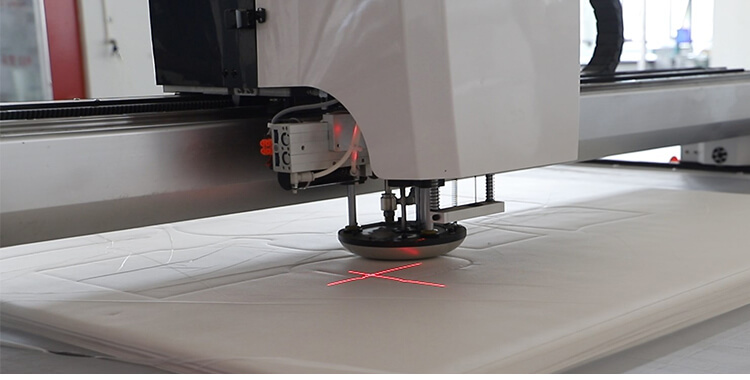

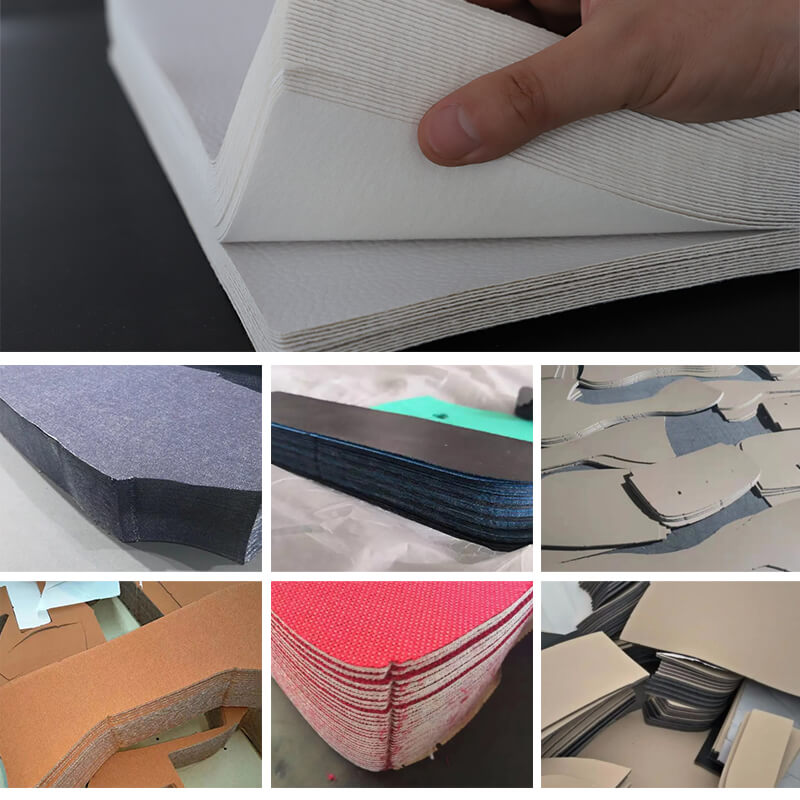

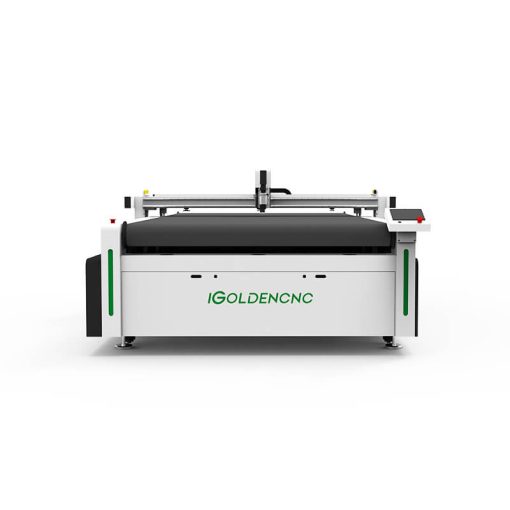

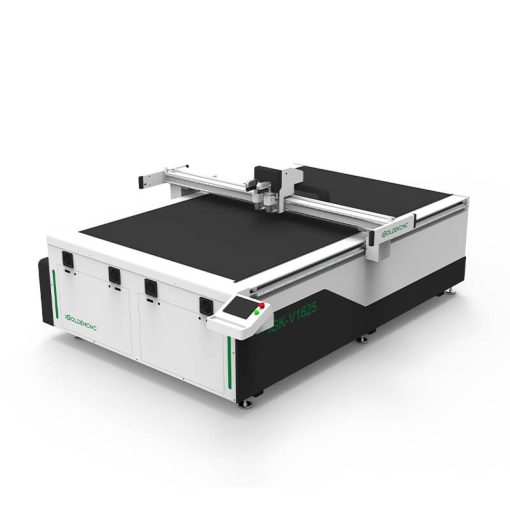

A multi-layer fabric cutting machine is a type of automatic cutting equipment specifically designed for cutting multiple layers of fabric at once. is an essential tool in the textile and garment industry, designed to cut multiple layers of fabric simultaneously. This significantly improves efficiency and precision in high-volume production settings. It is commonly used in industries such as garment manufacturing, upholstery, and textile production.

Multi-layer cutting machines are extensively used in the textile and apparel industries to cut fabrics such as cotton, polyester, nylon, silk, denim, and more. They can handle different types of fabrics, including woven, knitted, and non-woven textiles.

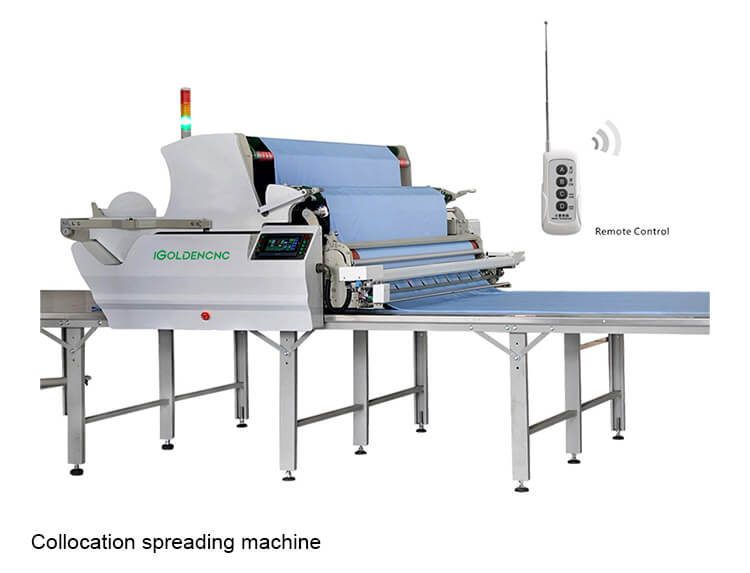

Multi layer cutting machine is a specialized tool designed to cut multiple layers of material at once, utilizing advanced technology and automation. These machines are equipped with features such as computerized controls, automatic feeding systems, and high-speed cutting mechanisms, ensuring precise and efficient cutting of a wide range of materials.

Reviews

There are no reviews yet.