Buyer Guide

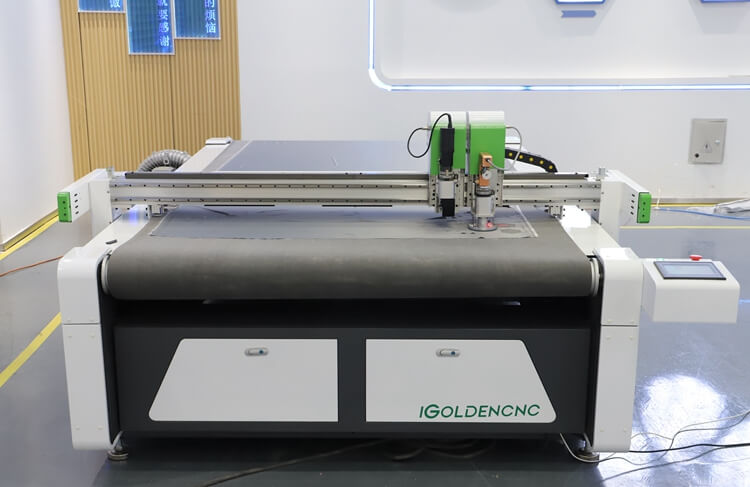

Automatic Fabric Pattern Cutting Machine

In the fast-paced world of apparel production, furniture upholstery, automotive interiors, and technical textiles, precision and speed are everything. Enter the automatic fabric cutting machine—a revolutionary tool that has transformed how industries cut, shape, and scale fabric-based products.

Gone are the days of manual scissors and labor-intensive processes. Today’s automated fabric cutters offer unparalleled accuracy, efficiency, and consistency, enabling manufacturers to meet high-volume demands without compromising on quality.

This expert guide explores everything you need to know about automatic fabric cutting machines—from how they work, their types and features, to how they can boost productivity and reduce waste in your textile operations.

Fabric Pattern Cutting Machine

An automatic fabric pattern cutting machine is a specialized device designed for efficiently cutting fabric into various patterns and shapes with high precision. These machines are widely used in the textile and garment industries.

Fabric Laser Cutter

Working Principle:

Laser machine tool lies in laser beams. CO2 laser machine uses a CO2 laser tube with a CNC system to irradiate the laser beam to the surface of the object. At the same time, the glass laser tube releases high energy heat to melt and evaporate the object surface to achieve CNC CO2 laser cutting and engraving. And in a CO2 laser engraving machine, light is produced when an electric current is passed through a gas-filled tube with mirrors at both ends. One mirror is fully reflective, while the other only lets some light through. Next, these mirrors direct the laser beam into the material to be cut. And the gas is usually a mixture of carbon dioxide, nitrogen, hydrogen, and helium.

In addition, CO2 laser beam is a very high-intensity beam of light. It is a kind of infrared ray with a single wavelength or color, which is invisible to the human eye. When the Co2 laser beam passes through the beam path from the resonator, its diameter is only about 3/4 of an inch. So, it may be reflected in different directions by many mirrors or “beam benders” before it is finally focused on the plate. And the focused CO2 laser beam passes through the nozzle hole before hitting the plate, as well as the compressed gas such as oxygen or nitrogen. Besides, higher CO2 laser power is for cutting and lower CO2 laser power is for engraving. Actually, the CO2 laser power is adjustable during operation. Laser power also affects the depth of CO2 laser engraving and the thickness of CO2 laser cutting.

Advantages:

- Precision: Ideal for intricate patterns, delicate fabrics, and complex designs (e.g., lace, micro-perforations).

- Speed: Fast processing for single-layer or thin fabrics.

- Versatility: Can cut, engrave, or mark fabrics (e.g., adding logos or decorative patterns).

- No Physical Contact: Minimizes fabric distortion or slippage during cutting.

- Automation: Fully compatible with CAD/CAM software for seamless digital workflow.

Disadvantages:

- Material Limitations: Risk of burning or melting synthetic fabrics (e.g., polyester, nylon) if settings are incorrect.

- Edge Finish: May leave charred or fused edges on natural fibers (e.g., cotton, wool), requiring post-processing.

- Cost: Higher initial investment and maintenance (e.g., laser tube replacement).

- Safety: Requires ventilation for smoke/fumes and safety protocols for laser exposure.

Best For:

This laser cutting system can cut any solid materials such as acrylic, wood, paper, metals, plastic, and all other elements.Because CNC laser cutting makes parts with no tool force, many parts can be fabricated without expensive tooling and fixtures. Small features, sharp corners, and closely spaced features are all handled more easily by laser cutting than by conventional milling or punching.

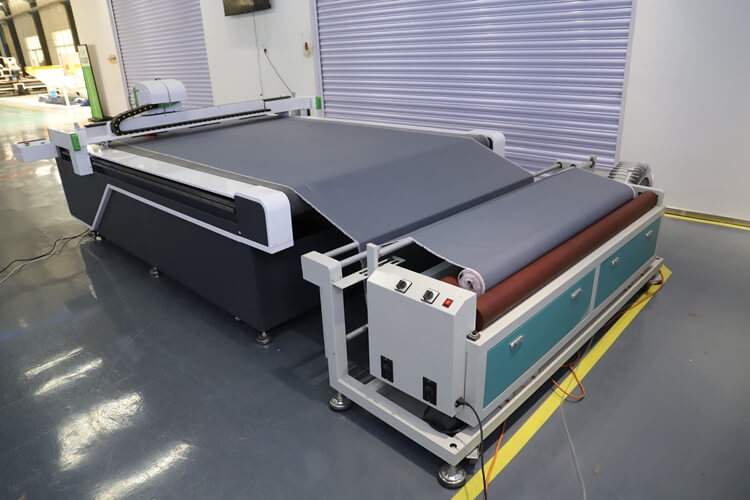

Fabric Oscillating Knife Cutter

Working Principle:

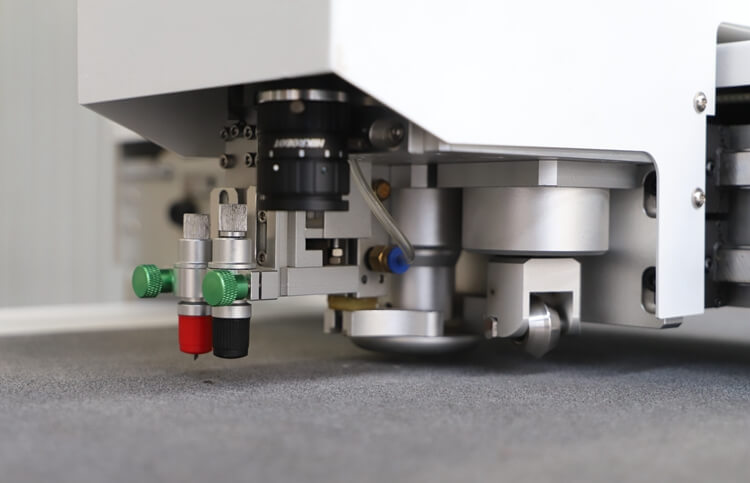

The CNC oscillating knife cutter adopts the visual control system, and the processing method is set through the software of the CNC knife plotter, and the cutting path is optimized according to the processing requirements of the material, and then the file is downloaded to the controller of the flat knife plotter machine.

The processing parameters (cutting speed, acceleration speed, cutting depth of the blade, etc.) are well set by the digital control panel of the CNC cutter to order the machine tool to process the parts.

Set the cutting parameters (cutting speed, acceleration, cutting depth, etc.) through the visual control panel, and the CNC tool cutting machine will automatically process the material according to the drawing.

The intelligent oscillating knife plotter uses the high-frequency vibration of the blade to achieve the purpose of cutting.

Advantages:

- Material Compatibility: Works well with thick, layered, or dense fabrics (e.g., denim, upholstery, leather).

- Clean Edges: Produces smooth, fray-free cuts without thermal damage.

- Multi-Layer Cutting: Efficient for bulk production (e.g., cutting 50–100 fabric layers at once).

- Cost-Effective: Lower operational costs (no laser consumables) and minimal fabric waste.

- Safety: No fumes or heat, making it safer for organic/natural fabrics.

Disadvantages:

- Complexity Limitations: Struggles with extremely intricate patterns compared to laser cutters.

- Blade Wear: Requires frequent blade replacement, especially with abrasive materials.

- Speed: Slower for single-layer cutting due to mechanical movement.

- Fabric Slippage: Risk of misalignment with stretchy or slippery fabrics unless clamped securely.

Best For:

A CNC knife cutting machine is a professional automated digital cutting system that uses the up and down high-frequency vibration of the blade to cut flexible materials.

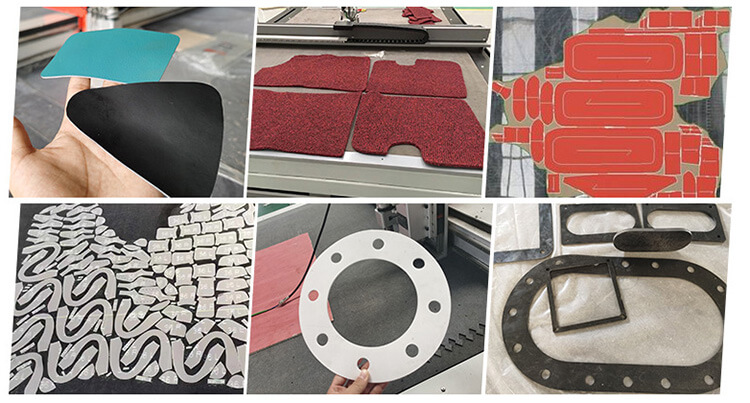

Applications

- Fashion Industry: Used for cutting patterns for garments, ensuring precise shapes and sizes for mass production.

- Home Textiles: Ideal for creating curtains, upholstery, and other home textile products.

- Automotive Textiles: Employed in cutting fabrics used in car interiors, such as seat covers and headliners.

- Technical Textiles: Suitable for cutting specialized fabrics used in industries like aerospace, healthcare, and sports equipment.

Key Comparison:

| Feature | Laser Cutter | Oscillating Knife Cutter |

|---|---|---|

| Precision | Superior for fine details | Good, but limited by blade thickness |

| Material Flexibility | Better for synthetics/technical fabrics | Better for natural/thick fabrics |

| Edge Quality | Risk of burning | Clean, smooth edges |

| Production Speed | Faster for single-layer | Faster for multi-layer |

| Operational Costs | Higher (energy, maintenance) | Lower (blade replacement only) |

| Safety | Requires ventilation | Minimal hazards |

Final Recommendation:

- Choose laser cutters for high-detail synthetic fabrics, engraving, or small-scale precision work.

- Opt for oscillating knife cutters for bulk natural fabric cutting, multi-layer projects, or heat-sensitive materials.

Conclusion

An automatic fabric pattern cutting machine is an essential tool for modern textile manufacturing. Its ability to streamline the cutting process, enhance accuracy, and reduce waste makes it invaluable for businesses looking to improve productivity and quality. Whether in fashion, home textiles, or technical applications, these machines play a crucial role in meeting the demands of the industry.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.