No products in the cart.

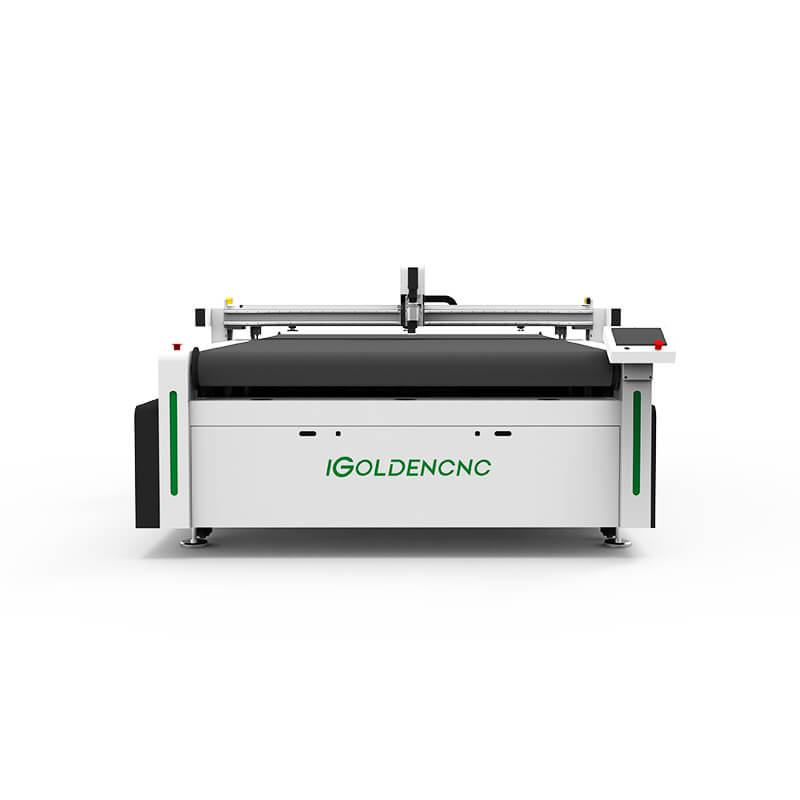

IGK-VA1625

CNC Knife Cutting Machine

The CNC oscillating knife cutting machine provides smooth, precise cuts, making it ideal for intricate patterns. This precision minimizes material waste and ensures consistent quality across large production runs.

This very wide range of flatbed cutting machines includes models with fixed beds and moving conveyors so that any material format – sheet, roll or a combination of both, can be processed.

The CNC knife cutting machine with auto feeding platform can automatically feed materials, saving time and effort. Flexible materials that can be precisely cut include vinyl, cardboard, fabric, textile, paper, leather, die, stencil, dieboard, foam, plastic, rubber, cork, carpet, felt and flexible polymers to make gaskets, stickers, signs, tags, packaging boxes, display boards, clothing, fashion, sportswear, car interiors, shoes and hats.

Reviews

There are no reviews yet.