Buyer Guide

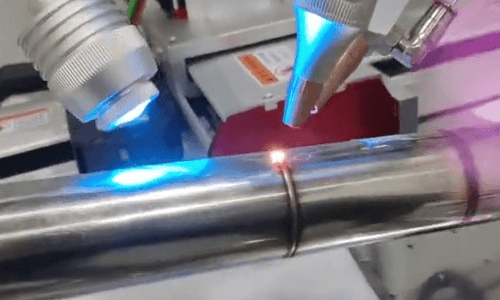

Automatic Robotic Laser Welding for Metal

Laser welding is a process that uses a laser beam to join metals or thermoplastics together to form a weld. As such a concentrated heat source, laser welding can be performed in thin materials at a high welding speed of meters per minute, while in thicker materials, narrow and deep welds can be produced between square-sided parts. Laser welding machines are widely used in the field of metal welding. Compared with traditional welding solutions, the operating cost is low and the welding surface is smooth. In addition, laser welding does not require the use of fillers. This is why laser welding has become more and more popular. It is different from other laser machines such as fiber laser marking machines and fiber laser cutting machines.

Robotic laser welding systems can be integrated with computer numerical control (CNC) systems and advanced software. This allows for automated operation, precise control of welding parameters, and integration with other manufacturing processes. It enables enhanced productivity, repeatability, and consistency in welding operations.

Robotic Laser Welding Machine

Robotic laser welding refers to the process of using a robotic system in combination with a laser beam to perform welding operations. It combines the precision and flexibility of robotics with the high-energy beam of a laser to achieve efficient and accurate welding results.

Robot laser welding machine is an automated welding equipment that uses laser technology for welding. Compared to traditional welding methods, robot laser welding machine has higher precision and efficiency.

The industrial laser welding robot is a sophisticated industrial automation system that combines robotics and laser welding technology to perform precise and efficient welding on metal components. With the upgrading of high-efficiency and intelligent equipment in the manufacturing industry, the cabinets and supporting sheet metals of new energy and other related industry chains simultaneously stimulate the demand for laser robot automatic welding processes. Robot-assisted production is becoming more and more common.

Features of robotic laser welding system:

- High precision: automatic fiber laser welding robot can achieve a high level of precision, resulting in accurate welds and a high-quality finished product.

- Faster welding speed: Since the laser beam is highly concentrated, it allows for faster and more efficient welding compared to traditional welding methods.

- Versatility & flexibility: Automatic robot laser welding machines are highly flexible and can handle a wide range of materials and thicknesses, including aluminum, stainless steel, and even plastics.

- Automated programming: Programming of the robotic laser welding machine can be automated, which means that it can be programmed to perform multiple welding tasks.

- Large work envelope: These machines have a large work envelope which allows them to handle large components and perform complex welding tasks.

CNC Automatic 6 Axis Robotic Laser Welding Machine

The six-axis fiber robot welding machine is the most typical robot. It is mainly composed of joints and connecting arm. The robot arm and wrist cooperate to complete the target trajectory movement, with 6 degrees of freedom in space.

Laser welding robotic system offer a great mix of speed, reach, payload capacity, and reach. These robots can cover the vast majority of laser welding applications. They excel in small to medium-sized welding tasks. Their excellent range of motion helps them weld complex part geometries.

6 Axis Robotic Laser Welding Machine

The six-axis robot consists of six joints: rotation (S axis), lower arm (L axis), upper arm (U axis), wrist rotation (R axis), wrist swing (B axis) and wrist rotation (T axis). The synthesis of 6 joints realizes the 6-DOF movement at the end, which makes the 6-axis automatic robot have many advantages such as high flexibility, super large load, and high positioning accuracy.

What is the role of each axis of robot arm?

- The first axis: It is the position of the link chassis, which is the load-bearing and core position. It carries the weight of the entire robot and the large swing of the robot left and right.

- The second axis: it is mainly an important axis to control the robot to swing back and forth and stretch.

- The third axis: It controls the robot to swing back and forth, but the swing range is smaller than the second axis, but this is also determined by the arm span of the six-axis robot.

- The fourth axis: It is an axis that controls the 180° free rotation of the upper arm, which is equivalent to the human forearm.

- The fifth axis: It is very important. When you adjust the position and accurately locate the product, you need to use the fifth axis, which is equivalent to the human wrist.

- Sixth axis: After the fifth axis is positioned on the product, some minor changes are required, and the sixth axis is required.

- The sixth axis is equivalent to a turntable that can rotate 360° horizontally. Products can be positioned more precisely.

Robotic Laser Welding Application

Laser welding is commonly used in metal materials and can join metal or non-metal materials.

Steel, aluminum and aluminum alloys are commonly welded using this process. Copper joints, copper-copper and copper-aluminum welding, which are often required in the production of lithium batteries, are also suitable for laser welding machines.

We have automation solutions for different industries, such as automobile production, electronic component manufacturing, medical equipment, and battery pack production in the energy field. Please contact us for better solutions. Robotic laser welding is an accurate, clean and flexible option for a wide variety of welding applications.

Why choose a fiber laser welding machine

High Speed

The laser can heat metal extremely quickly while limiting the risk of deformation.

This technology is particularly effective for welding a large number of metal plates, so it is widely used in the automotive industry.

Welding Precision

They allow for localized, very fine, very clean, almost invisible welding.

They are especially suitable for welding small parts.

This type of welding is very popular in the dental and jewelry industries because it provides the most beautiful welding.

The laser beam can also be divided into several beams to provide more precise welding.

Wide range of applications

Laser welding machines are mainly used for welding metals, including refractory metals.

They can also be used to weld non-metallic parts such as porcelain and glass.

You can use them to weld parts of very different shapes.

No wear

The laser welding machine operates without contact, so the machine has no risk of wear.

There is also no need to change tools or electrodes, which is an obvious advantage in reducing waste.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.