No products in the cart.

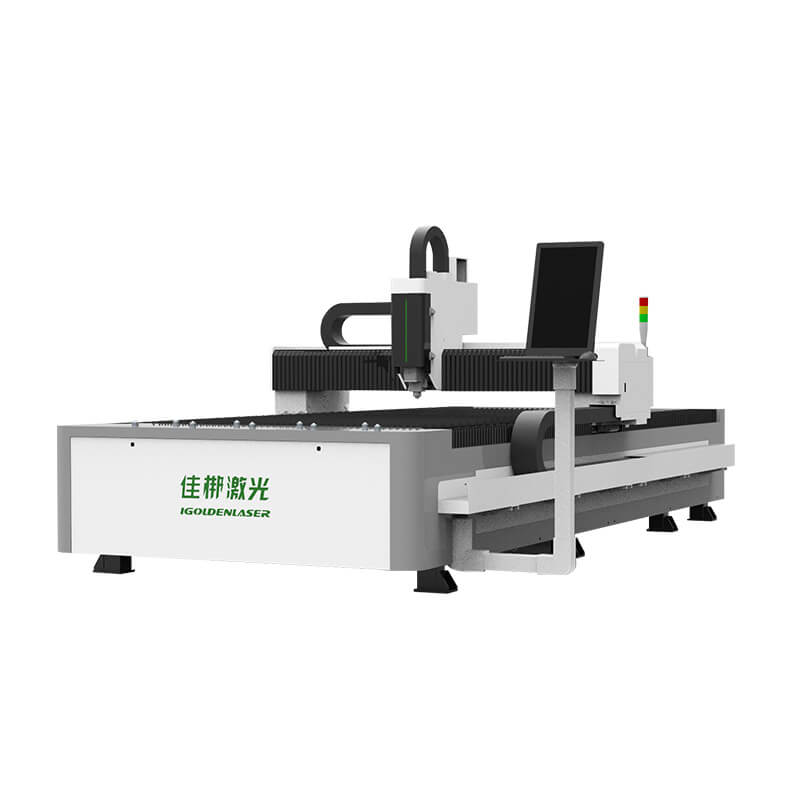

Economical Fiber Laser Cutting Machine

iGR-L laser cutting machine is the new generation of safe, high efficiency, energy saving, entry-level metal sheet laser cutting equipment, using heavy-duty welding bed, aviation aluminum beam, equipped with high-efficiency transmission system such as imported high-precision double-drive rack and pinion and linear guide, combined with the advanced CYPCUT control system, the precision CNC fiber laser cutting machine is assembled. The machine has good dynamic performance and fast servo response, with small slit and small thermal effect, especially suitable for sheet metal processing.

Richard –

I was wary of purchasing a Chinese-made laser cutter off the internet, but the reviews convinced me to give it a try. Got this unit in 28 days. No trouble in assembly and parameter setting. I’ve tried it to cut 304 and 316 stainless steel plates and pipes for kitchenware and gotten the cleanest cuts. It’s a powerful all-in-one machine for both sheet metals and tubes. No regrets with the buying of this great cutter.

John –

Cuts extremely well. Starts easily. My first task with this machine was to cut the 3/8 steel plate, and it cut much better than the plasma units I am used to. I should mention that this fiber laser machine does not require you to touch the work to start the cutting with CNC controller which makes it very easy to use. A great laser cutter for sheet metal at a great price.