Buyer Guide

Best Vinyl Cutting Machine for Small Business

In the world of crafting and design, the vinyl cutting machine has become an indispensable tool. This versatile device allows users to create intricate designs, custom decals, and professional-grade signage with ease. Whether you’re a hobbyist or a professional, understanding the capabilities and applications of a vinyl cutting machine can open up a world of creative possibilities.

Vinyl Cutting Machine

A vinyl cutting machine is a device that uses a small blade to cut out shapes and letters from sheets of vinyl. The machine is controlled by a computer, which sends precise instructions to the blade, allowing it to cut out intricate designs with high accuracy. These machines are commonly used in various industries, including signage, apparel, and home décor.

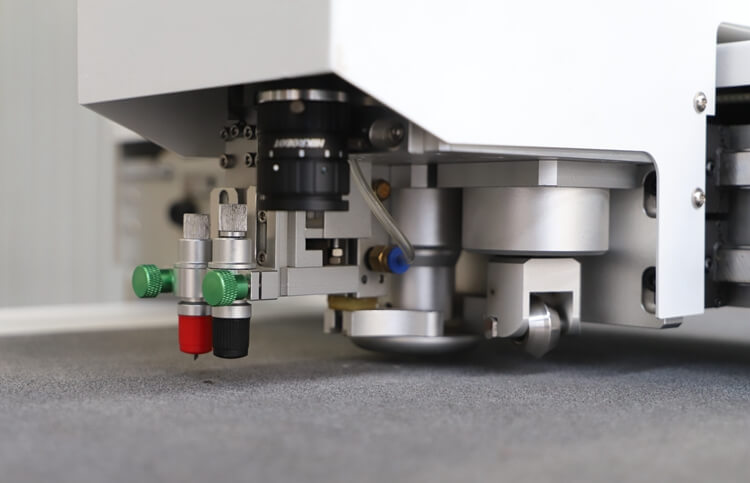

Flatbed cutting plotter is a type of smart CNC digital cutting machine with automatic cutting & finishing for vinyl stickers, vinyl labels, vinyl lettering, vinyl signs, vinyl lettering, digital printing & signage in home shop, small business, or industrial manufacturing. It’s a vinyl roll feed cutter with automatic feeding & lifting platform and automatic vacuum chuck. Three knives are equipped on the digital cutting machine, one kisscut knife, one cutting knife, and one creasing wheel. One pen is equipped for writing and drawing. The digital cutter can precisely and quickly complete full cutting, half cutting, creasing and marking. Scribing, indentation, half-cutting, and full-cutting can be achieved at one time on the CNC digital cutter. In addition, CCD camrea is an important part to improve the cutting accuracy.

Cutting Tools and Capabilities

Digital knife cutting machines are equipped with a variety of cutting tools:

- Drag Knife: Used for cutting a wide range of materials up to 1/4 inch depth. Provides the speed and precision of a CNC router.

- Tangential Knife: A more robust tool for cutting thicker, harder, and heavier materials with high accuracy.

- Oscillating Knife: Ideal for cutting flexible materials like packaging foam, cardboard, and corrugated plastic. Provides clean, precise cuts.

- Creasing Wheel: Used for cutting abrasive and hard-to-cut materials. Resists abrasion better than jagged tools.

- Kiss-Cut Knife: Specialized for cutting vinyl, allowing for precise depth control.

These machines have a cutting head that oscillates or vibrates at a high frequency (typically 60-100 Hz) as it cuts through the material.

The vibrating motion allows the blade to slice through vinyl cleanly, resulting in very accurate cuts and intricate designs.

The vibration helps the blade cut through thicker, stiffer, or textured vinyl materials that would be more difficult to cut with a standard vinyl cutter.

Vibration-assisted vinyl cutting machines are a specialized type of vinyl cutter that use a vibrating cutting head to enhance the cutting performance. The vibrating motion of the blade helps to improve the precision and efficiency of cutting through vinyl and other thin materials.

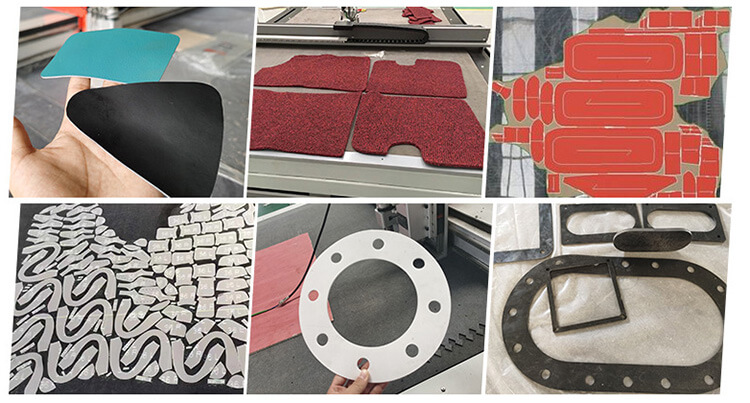

Vinyl sticker is a wall decal cut with a flatbed vinyl cutting plotter. A vinyl sticker is also known as wall sticker, tattoo, it is used for hobbyists or commercial use as a sign to promote brand, service, or business on sandwich board, vehicle, or in a shop window. Vinyl label is also known as vinyl decal. Vinyl signage is a form of outdoor advertising. Most signs are now digitally cut with CNC vinyl cutting plotters which are capable of cutting a sign outdoor billboard on vinyl material.

Vinyl lettering is to cut vinyl out of individual letters. Vinyl lettering is to cut directly from colored vinyl material. Vinyl lettering is to cut from durable vinyl material to smooth surfaces.

Vinyl Cutting Machine Parameter

| Technical indicators | parameter |

| Model | iGK-4060(Size can be customized) |

| Working Size | 400mm*600mm |

| Tools Group | Cutting Tools;Kiss-cutting Tool;Creasing Tool;CCD Camera; High Speed Oscilating Knife(Pro only) |

| Max Cutting Speed | 1500mm/s (according to the material) |

| Cutting Thickness | <5mm |

| Positioning Accuracy | 0.05mm |

| Profile Format | DCF,PLT,PDF,AL |

| Transmission Method | Ethernet Port |

| Rated Power | 2.5KW |

Key Features of Digital Knife Vinyl Cutting Machines

- Digital knife cutting machines are designed for high-precision cutting of flexible and semi-rigid materials like vinyl, fabric, leather, foam, and more.

- High Speed: These machines can perform cutting operations at high speeds, improving productivity.

- Automatic Loading and Unloading: Many models feature automatic loading and unloading systems, reducing manual labor.

- Intelligent Typesetting: The machines can perform intelligent typesetting and layout optimization to maximize material utilization.

- Low Operating Costs: Digital knife cutting offers a cost-effective solution compared to traditional manual cutting methods.

Applications of Digital Knife Vinyl Cutting Machines

Digital knife cutting machines find use in various industries, including:

- Leather Industry: For cutting leather, shoe soles, linings, and uppers with high precision.

- Fashion and Apparel: Fabric cutting with improved quality, productivity, and speed.

- Graphics Industry: Cutting intricate graphics, banners, signage, and more.

- Packaging Industry: Creating packaging components like boxes, folders, and honeycomb structures.

- Textile Industry: Cutting a variety of textile materials with efficiency.

Types of Vinyl Cutting Machines

There are several types of vinyl cutting machines available, each with its own unique features and capabilities. Here are some of the most common types:

Desktop Vinyl Cutters

Desktop vinyl cutters are compact and portable, making them ideal for small businesses and hobbyists. These machines are typically user-friendly and come with a variety of features that make them perfect for beginners.

Professional Vinyl Cutters

Professional vinyl cutters are larger and more robust, designed for high-volume production. These machines offer greater cutting speed, precision, and versatility, making them suitable for commercial use.

Laser Vinyl Cutters

Laser vinyl cutters use a laser beam to cut through the vinyl. These machines offer exceptional precision and can cut through thicker materials that traditional blade cutters cannot handle.

How Does a Vinyl Cutting Machine Work?

The operation of a vinyl cutting machine involves several key steps:

- The first step is to create a design using specialized software. This software allows users to create or import designs, which can then be sent to the vinyl cutter.

- Material Loading: The vinyl sheet is loaded into the machine, ensuring it is properly aligned.

- Cutting: The machine’s blade follows the design’s path, cutting through the vinyl but not through the backing paper.

- Weeding: After cutting, the excess vinyl is removed, leaving only the desired design.

- Application: The final step is to transfer the cut vinyl to the desired surface using transfer tape.

Frequently Asked Questions (FAQ)

What materials can a vinyl cutting machine cut?

Vinyl cutting machines can cut a variety of materials, including adhesive vinyl, heat transfer vinyl, cardstock, and paper. Some machines can also cut fabric, leather, and thin metal sheets.

Can I use a vinyl cutting machine for commercial purposes?

Yes, many businesses use vinyl cutting machines for commercial purposes, such as creating custom signage, apparel, and vehicle graphics.

How do I maintain my vinyl cutting machine?

Regular maintenance includes cleaning the machine, checking and replacing the blade, and ensuring the software is up to date. Refer to the manufacturer’s instructions for specific maintenance guidelines.

What is the difference between a desktop and a professional vinyl cutter?

Desktop vinyl cutters are smaller and more portable, making them ideal for hobbyists and small businesses. Professional vinyl cutters are larger, more robust, and designed for high-volume production, offering greater cutting speed and precision.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.