Buyer Guide

Cheapest 4×8 Plasma Table for Sale

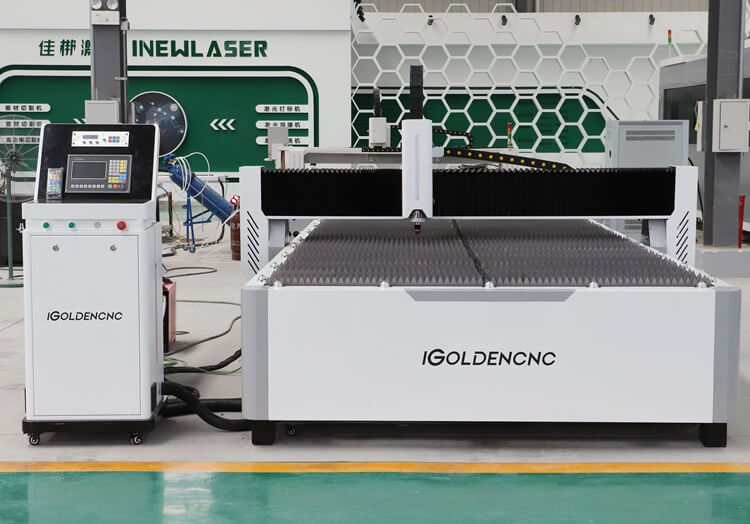

Cheapest 4×8 Plasma Table

This is a 4×8 CNC plasma table cutter,it is very popular in the metal process industry.The 4×8 plasma table cutter has many advanced CNC plasma parts.Such as the high precision plasma cutting head, which has high precision cutting performance and cutting speed. And The aluminum profile gantry beam of this machine is a light duty and fast speed.A 4×8 CNC plasma cutting table is a versatile tool for small to medium-sized businesses and workshops involved in metal fabrication and metalworking. Its ability to cut metal sheets with precision, speed, and efficiency makes it an essential asset for those requiring high-quality and cost-effective metal cutting solutions.

so if you like this 4×8 plasma table for sale, we will provide the most affordable price and the most comprehensive service, please leave your contact information.

iGOLDEN CNC plasma cutting tables are configured with a motion controller that sets the bar for acceleration and deceleration rates, a plasma cutter that increases cut speeds and outlasts competing consumable life cycles by nearly 3x, and a linear motion system that hits gantry and torch travel speeds of up to 500 ipm. All of these features accelerate cost savings for our customers. The faster cut speeds and higher acceleration and deceleration rates reduce job cycle times and increase the amount of metal parts your shop is able to sell.

Key Features of Cnc Plasma Cutting Table:

- Cutting Area: The 4×8 5×10 table provides a spacious cutting area, allowing for the processing of large metal sheets. This is particularly useful for industries that require large-scale metal cutting, such as metal fabrication, manufacturing, and construction.

- Plasma Cutting: Plasma cutting is a thermal cutting process that uses a high-velocity jet of ionized gas (plasma) to melt and remove metal from the workpiece. It is known for its speed and versatility in cutting various thicknesses of metal.

- CNC Control: The machine is controlled by a computer with CNC software. Operators can input cutting designs, and the CNC system precisely controls the movement of the plasma torch to follow those designs, resulting in accurate and repeatable cuts.

- Precision: CNC plasma cutting table offer high precision and accuracy in cutting metal materials, making them suitable for applications that require tight tolerances and intricate designs. Material Compatibility: These machines can cut a variety of metal materials, including mild steel, stainless steel, aluminum, and other alloys. They are versatile and adaptable to different types and thicknesses of metal.

- Speed and Efficiency: Plasma cutting is a fast and efficient process. The high cutting speeds and minimal heat-affected zones reduce production time and labor costs. Customization: Operators can create custom cutting designs, making it possible to produce unique components and parts. This is useful for applications in which specialized or one-of-a-kind pieces are required.

- Minimal Material Waste: Plasma cutting produces minimal waste, which is cost-effective and environmentally friendly.

- Reduced Setup Time: CNC plasma cutting table are designed for quick and easy setup, which is advantageous when switching between different cutting tasks or designs.

CNC Plasma Cutter

The term CNC stands for Computer Numerical Control. That is a CNC cutter will cut through metal using ionized gas with computerized command. A CNC plasma cutter is a type of computer numerical controlled automatic cutting system that uses ionized gas torch to cut metals into different profiles and shapes with CNC controller, including mild steel, stainless steel, carbon steel, galvanized steel, hot rolled steel, cold rolled steel, iron, brass, copper, alloy, aluminum, bronze, and titanium.

A CNC cutter kit is composed of machine frame, controller, power supply, gas torch, blade or sawtooth table, driver, motor, control system, software, guide rail, ball screw, optional parts and consumable parts. Some of the synonyms of a plasma cutter are cutting torch, arc cutter, cutting machine, arc welding cutter, cutting system, plasma table, metal cutter, cutting tool, arc welding machine, or plasma cutting device.

What Are The Types of Plasma Cutters?

The most common types of plasma cutters include the handheld and CNC variant (hobby types and industrial types). The most common power supplies include Huayuan power supply and Hypertherm power supply.

According to the working methods, the kits can be divided into air kits, dry kits, semi-dry kits and underwater kits.

According to the cutting quality and precision, you will meet the types of ordinary, fine, laser-like, and so on.

According to the appearances, the three types are listed bellow:

Portable CNC Kits

The machine is portable, easy to setup, compact in structure, small in space and low in manufacturing cost. However, due to the limitation of the cantilever structure, the stress conditions are poor, the transverse deformation is prone to occur, the transverse cutting width is limited, and the rigidity is poor during high-speed machining.

Gantry CNC Kits

The gantry-type supporting method is bidirectionally supported, the force is more uniform, the equipment has good rigidity, and can achieve a large lateral span, usually up to 3 to 10m. However, the equipment installation requirements are high, the structure is relatively large, and it takes up more plant area. The driving mode is divided into unilateral driving and bilateral driving. Unilateral drive and bilateral drive each have their own characteristics and applications. The unilateral drive avoids the high-precision synchronous control and complicated structure of the bilateral drive. However, due to the offset of the center of mass and the driving force does not pass through the center of mass, asymmetric inertial force will be generated during operation, which is prone to vibration, deformation and tilt. Therefore, it can only be used in a small span. The double-sided drive structure is relatively complicated and requires high-precision synchronous control on both sides, which can be used for a larger span and more stable movement.

How To Use A CNC Plasma Cutter & Cutting Table?

For people who have never used a gas cutter or plasma table with computer-controlled controller. This is an easy-to-follow guide with software installation, setting, debugging, parts assembly, setup, and operation.

Manual Non-Contact Cutting.

Step 1. Touch the torch roller to the workpiece, and adjust the distance between the nozzle and the plane of the workpiece to 3-5mm. (When the machine cuts, the “Cut Thickness Selection” switch is upscale).

Step 2. Turn on the torch switch to ignite the plasma arc. After cutting through the workpiece, move to the cutting direction at an even speed. The speed is based on the premise of cutting through. Too slow will affect the quality of the incision and even break the arc.

Step 3. After working, turn off the torch switch and the arc goes out. At this time, compressed air is sprayed out at a delay to cool the torch. After a few seconds, the ejection stops automatically. Remove the torch to complete the entire process.

Manual Contact Cutting.

Step 1. The “Cut Thickness Selection” switch is at the low level, and it is used when cutting thinner metal plates by a single machine. Step 2. Place the torch nozzle at the starting point of the workpiece to be cut, turn on the torch switch, ignite the arc, cut through the workpiece, and then move uniformly along the cutting direction. Step 3. After working, open and close the torch switch. At this time, the compressed air is still spraying out. After a few seconds, the spraying will stop automatically. Remove the torch to complete the entire process. Automatic Cutting. Step 1. Automatic cutting is mainly suitable for cutting thick workpieces. Select the “Cut Thickness Selection” switch position.

Step 2. After removing the torch roller, the torch and the semi-automatic machine tool are firmly connected, and the attachment is provided in the random accessories.

Step 3. Connect the power of the semi-automatic cutting system, and install the radius rod or guide rail according to the shape of the project (if you need to cut arc or circle, a radius rod is required).

Step 4. If the torch switch plug is turned off, replace the remote switch plug (prepared in the accessories).

Step 5. Adjust the appropriate walking speed according to the thickness of the workpiece. And set the “up” and “down” switches on the semi-automatic cutter to the cutting direction.

Step 6. Adjust the distance between the nozzle and the workpiece to 3-8mm, and adjust the center position of the nozzle to the starting strip of the workpiece slit.

Step 7. Turn on the remote control switch. After cutting through the workpiece, turn on the power switch of the semi-automatic machine to cut. In the initial stage, pay attention to the seam at any time and adjust to a suitable speed. And pay attention to whether the two machines work normally at any time.

Step 8. After cutting, turn off the remote control switch and the power switch.

At this point, the entire process is completed. Manual Cutting Circle. According to the material and thickness of the part, choose the single or parallel cutting method, and choose the corresponding cutting method. Tighten the cross bar in the random attachment to the screw hole on the torch holder. To the required radius and tighten, then adjust the distance from the tip to the torch nozzle according to the length of the workpiece radius (the width of the slit must be considered). After adjustment, tighten the center fastening screws to prevent loosening, and loosen the cage to tighten the knurled screws. At this point, you can cut the workpiece.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.