Buyer Guide

CNC Knife Cutter Machine for PE and EVA Foams

CNC knife cutter machines are widely used in industries such as packaging, textile, automotive, aerospace, and signage. They offer precise and efficient cutting capabilities, enabling the production of intricate shapes and patterns with minimal material waste.

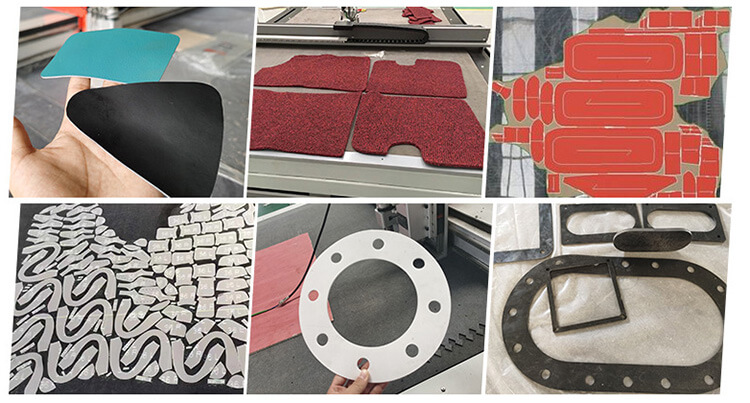

Affordable cnc oscillating knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

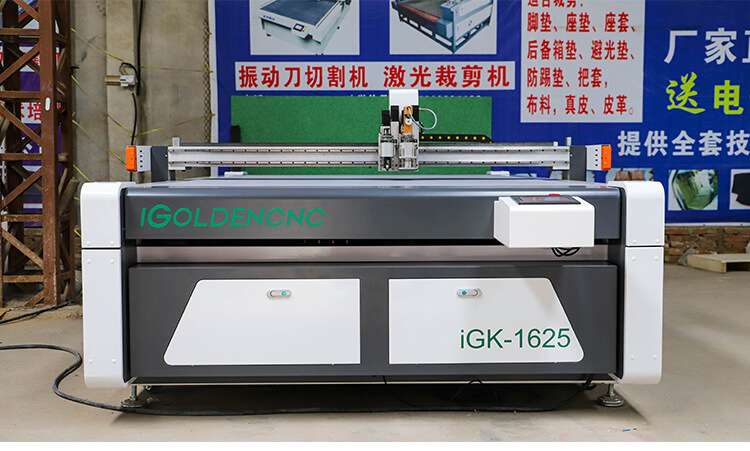

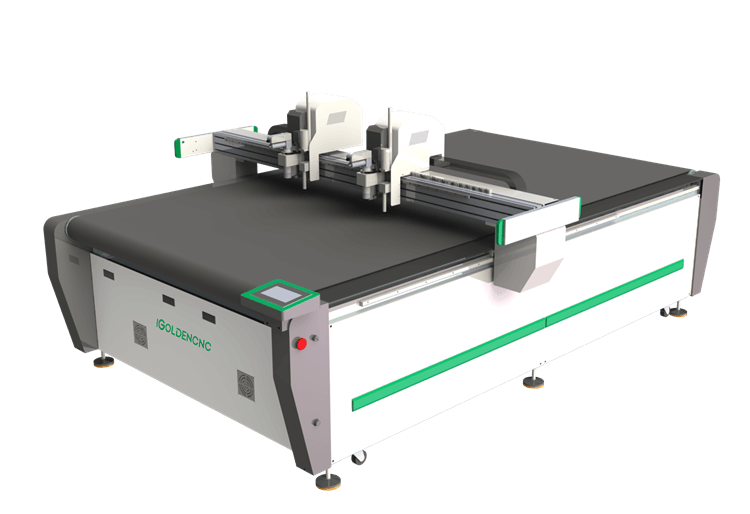

CNC Knife Cutter Machine

A CNC knife cutter machine, also known as a CNC cutting machine or a CNC oscillating knife cutter, is a computer-controlled cutting system specifically designed for precision cutting of various materials. It utilizes a vibrating or oscillating knife, which moves rapidly up and down to cut through the material.

Affordable cnc oscillating knife machine have two types: ① CNC Router machine add oscillating knife cutting knife head (Knife together with spindle independent work, compatible with cnc router cotrol system, and running perfectly, Solve the processing needs of soft materials); ② Professional oscillating knife cutting machine ( Professional and efficient ). Accordding to functions: can be divided into oscillating knife cutting , round knife cutting, pneumatic knife cutting. you need to accordding to different material shapes cutting, choose different knives.

CNC can provide all kinds CNC Knife Cutter Machine for sale:

CCD camera series: automatic edge finding, automatic scanning, automatic imaging system.

Auto feeding series: automatic loading and unloading; intelligent typesetting; multi-layer cutting.

Multi heads series: double heads can cut same shapes, also can cut different shapes at the same time.

CNC knife cutter machine table size:

CNC oscillating knife cutting machine for sale have model: 6090, 1390, 1410, 1610, 1325, 1530, 2030, and working table size 600*900mm, 900*1300mm, 1000*1400mm, 1000*1600mm, 1300*2500mm, 1500*3000mm, 2000*3000mm etc, maybe some regions describe cnc knife cutter machine table size with feet: 3*4, 3*5, 4*8, 5*10 etc. We also accept custom table sizes,to meet customer needs.

CNC Knife Cutter Machine Processing advantages

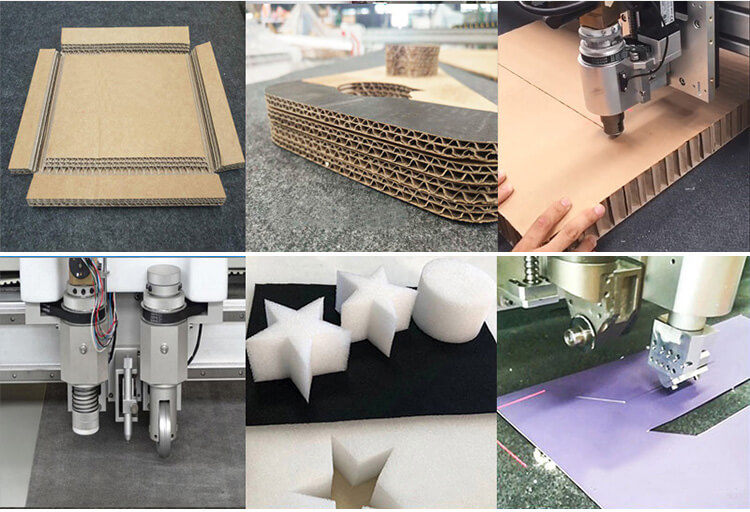

With the continuous development of numerical control technology, more and more customers choose to use smart cutting equipment instead of workers. It uses advanced oscillating knife cutting technology to select different tools according to material thickness and hardness. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

There are 6 advantages to using the CNC Knife Cutter Machine to cut the foam:

1. More flexible; EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials; automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting; can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized; AMOR EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Different types of tools can be configured; customers can configure different processing tools according to the processing materials – round knife, pneumatic knife, punching knife, vibrating knife, and other cutter heads to configure freely to cut other materials except for foam;

6. Achieve higher cutting efficiency; AMOR EVA foam cutting machine adopts Japanese Mitsubishi servo motor with cutting speed of up to 2000mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

CNC Knife cutter machine application

Affordable cnc Digital knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

Oscillating Knife Details

Cutting Capabilities

CNC knife cutter machine are versatile and can cut a wide range of materials, including but not limited to:

- Soft materials: Foam, rubber, gaskets, textiles, carpets, felt, leather, etc.

- Rigid materials: Cardboard, corrugated board, honeycomb board, thin plastics, composite materials, etc.

- Other materials: Vinyl, paper, cork, magnetic sheets, adhesive-backed materials, and more.

- The oscillating knife’s high-frequency motion allows for clean and precise cuts, even in intricate designs or complex patterns.

Additional Tool Option

In addition to the oscillating knife, CNC knife cutter machines can often accommodate other cutting tools or attachments, expanding their capabilities. Some common additional tools include:

- Creasing wheels: Used for creating creases or scoring lines in materials like cardboard or paper, enabling easier folding or bending.

- Perforation wheels: Used to create perforated lines for tear-off sections in materials like paper or cardboard.

- Routing attachments: Used for cutting harder materials like acrylic or wood, where an oscillating knife may not be suitable.

- The ability to interchange tools allows for more versatility in the types of materials and applications that can be handled by the machine.

High Precision and Repeatability

CNC knife cutter machines offer excellent precision and repeatability in cutting. The computer-controlled nature of the machine ensures accurate cutting paths, resulting in consistent and high-quality finished products. This is especially beneficial for industries that require precise fitting, such as packaging or automotive interior components.

Design Flexibility

With the help of specialized software, CNC knife cutter machines can process various design file formats, allowing for flexibility in design creation. Designs can be imported from computer-aided design (CAD) software or created directly within the cutting software. This flexibility enables customization, prototyping, and small-batch production with ease.

Production Efficiency

CNC knife cutter machines streamline the cutting process, reducing manual labor and increasing production efficiency. Once the cutting program is set up, the machine can autonomously execute the cutting tasks, optimizing material usage and minimizing waste. This automation also allows for faster turnaround times, enabling manufacturers to meet tight deadlines and handle larger production volumes.

Integration with Workflow

CNC knife cutter machine can be integrated into a larger production workflow, connecting with other equipment or systems. This integration facilitates seamless material handling, automated nesting (arranging shapes to minimize material waste), and data exchange, enhancing overall productivity and efficiency.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.