iGP-3A 1325

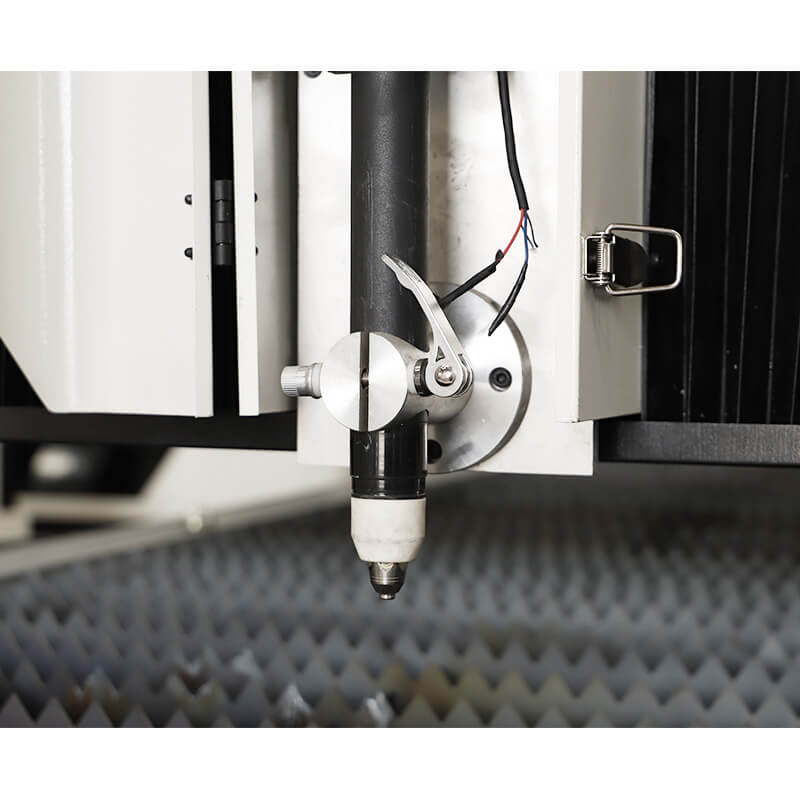

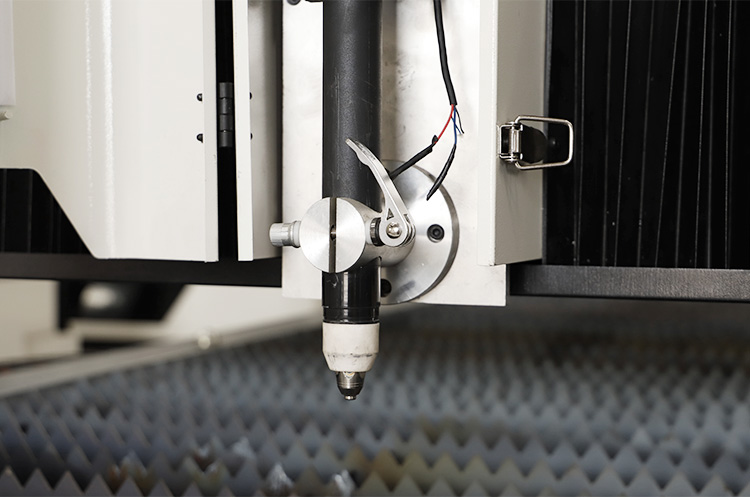

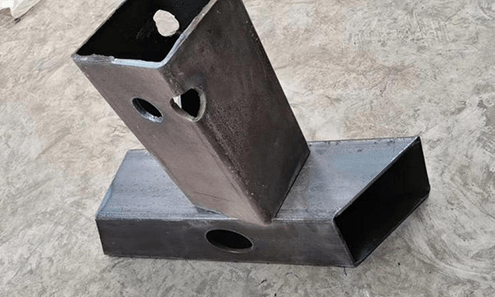

Plasma Cutting Machine

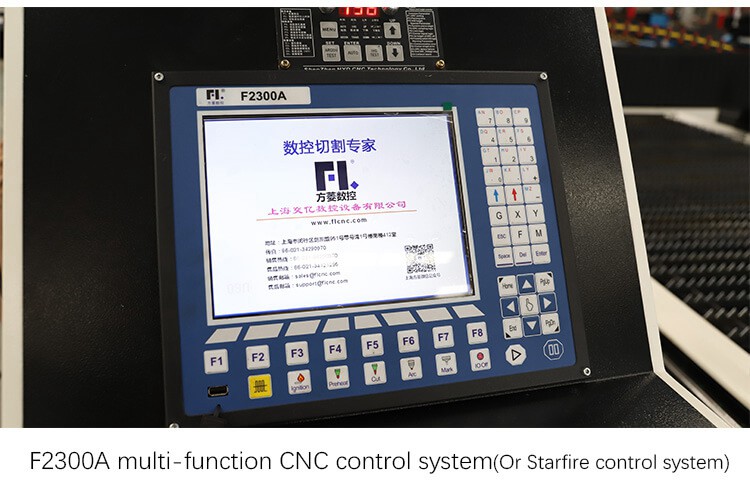

CNC plasma table is a type of plasma CNC cutter with custom welding table top, which can be well adapt to cut metal projects with different sizes.Flat CNC plasma cutting machine is the most popular plasma cutting machine,It is the perfect choice for cutting thick metal plates. It saves time and labour costs. This is the characteristic of iGOLDENCNC products, combined with a set of competitive configurations.

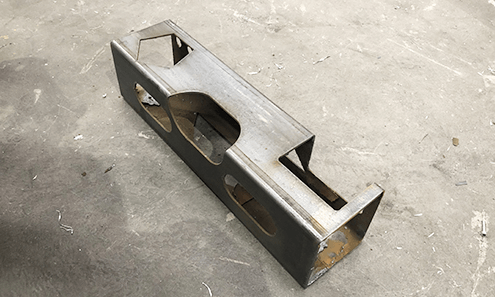

The 4×8 plasma table is suitable for sheet metal cutting, kitchenware, components, decorations industry, ship building, construction equipment, transport equipment, transport equipment, bridge building, wind power, structural steel, agriculture machinery, environmental protection equipment, etc.

Reviews

There are no reviews yet.