Buyer Guide

CO2 Laser Acrylic Cutting Machine for Advertising Industry

CO2 Laser Acrylic Cutting Machine

CO2 laser acrylic cutting machines are a valuable asset in the advertising industry, enabling the production of high-quality, custom signage and promotional materials with precision and efficiency. Their ability to cut and engrave acrylic sheets makes them a versatile tool for advertising professionals.2023 best acrylic laser cutting machine is used to cut plastics, clear and colored acrylic sheets (plastic glass, lucite, plexiglass) as letters, numbers, signs, logos, patterns, arts and crafts. Now the affordable CO2 laser cutting machine for sale at a low price.

Acrylic is a transparent plastic homopolymer known more usually by the trade name “plexiglass”. Acrylic is very similar to polycarbonate in that it is suitable for using as an impact resistant alternative to glass. There are clear, white, black, bullet-resistant, mirrored, matte finish, non-glare, sandblasted (frosted), or UV filtering acrylic sheets in the world. When you work on acrylic engraving and cutting in your work shop or home shop, you should buy a laser cutter with CO2 laser source. So, Let’s take a guide to learn what is a laser cutter for acrylic?

Acrylic Laser Cutting Machine Features

- Materials: Acrylic sheets, also known as plexiglass or PMMA (Polymethyl Methacrylate), are commonly used in the advertising industry due to their clarity, durability, and versatility. They come in various colors and thicknesses.

- Design and Software: Design files are created using graphic design software like Adobe Illustrator or CorelDRAW. These files are then loaded into the laser cutting software, which controls the machine’s movements and settings.

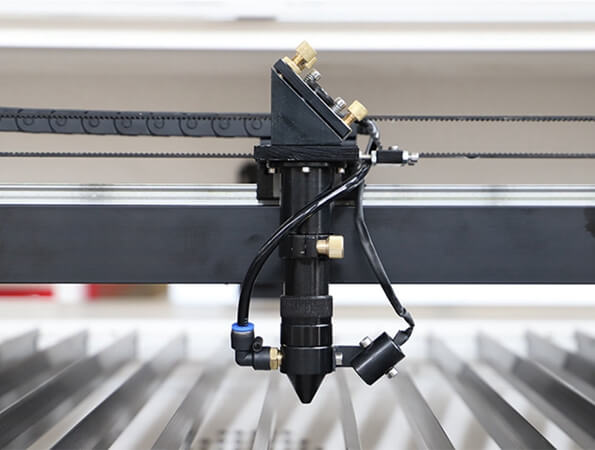

- Machine Setup: The acrylic sheet is placed on the cutting bed of the CO2 laser machine. The machine’s focal point and settings (e.g., laser power and speed) are configured according to the thickness and type of acrylic being used.

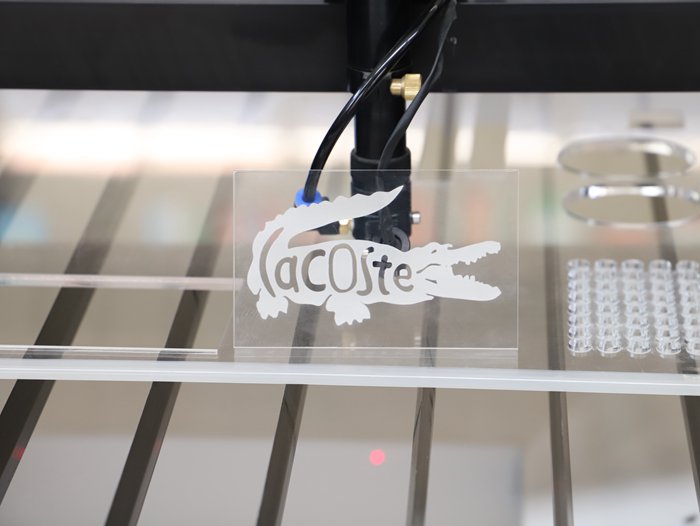

- Cutting: The laser head moves over the acrylic sheet following the design file’s path. It emits a high-powered CO2 laser beam that melts and vaporizes the acrylic, leaving behind a clean and precise cut. This process can cut through the acrylic or create intricate designs with high precision.

- Engraving: In addition to cutting, CO2 laser machines can engrave the surface of the acrylic. This is commonly used for adding text, logos, or decorative patterns to create visually appealing signage and displays.

- Quality and Precision: CO2 laser machines offer excellent precision and quality. They can produce intricate and detailed designs with smooth edges and clean cuts, making them suitable for high-end advertising materials.

- Versatility: These machines can work with various acrylic thicknesses and types, making them adaptable to a wide range of advertising projects.

- Cost-Efficiency: While the initial investment in a CO2 laser acrylic cutting machine can be significant, it can be cost-effective in the long run due to reduced labor costs and material waste. It’s also suitable for both small-scale and large-scale production.

What’s the difference between acrylic laser cutter and acrylic CNC router?

They are all CNC machines, able to perform intricate cuttings of non-metals, such as acrylic sheet, PVC, wood, MDF, etc. But there are also many differences when you use it to make dedicate works, it is all because: Laser cutting is a process of heat-melt-burn by high energy laser beam; while CNC Router cutting is a kind of high-speed-milling away materials from workpiece. As one of acrylic laser cutting machine manufacturers in China, we also supply CNC router for acrylic sheet cutting, you can choose any machine on your need.

Laser Acrylic Cutting Machine Applicable Industries

Acrylic laser cutting system is applied to acrylic, cloth, leather, toys, computer embroidery cutting, mould, crafts, bamboo and wood, advertising and building decoration, packaging and printing, paper products industries with affordable price.

Laser Acrylic Cutting Machine Applicable Materials

Acrylic laser cutting system is available for engraving and cutting acrylic, color plates, ABS board, rubber, plastic, cloth toys, leather, wool, crystal, glass, ceramic tile, jade, bamboo products, wood products.

RELATED PRODUCTS

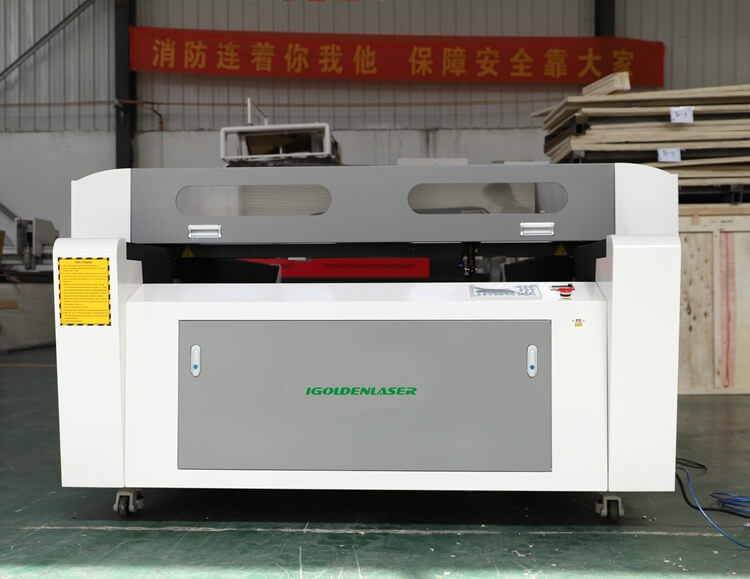

The acrylic laser engraving machine is the latest 1390 CO2 laser engraving machine. This plastic engraving machine is suitable for a variety of materials, with a smooth cutting edge, no polishing, low noise, no dust, fast processing speed, high precision, less waste, and efficiency high advantage. It is the best choice for upgrading acrylic laser engraving machines in various industries. The laser engraving machine price is cheap.

Main Parts Of Acrylic Laser Engraving Machine

What is CO2 Laser Cutting Machine?

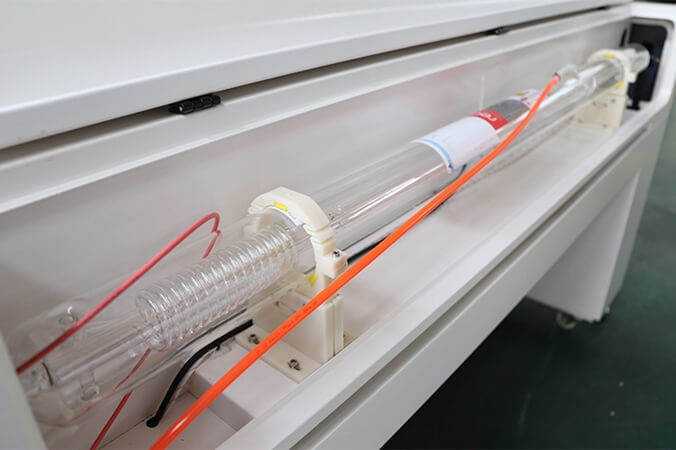

The CO2 laser cutter adopts CO2 laser source (CO2 laser cutting technology) to cut and engrave non metals and soft metals. Therefore, some people also call it dual use CO2 laser cutting machine or mixed laser cutting machine. And it is consisted of various CO2 laser kits, such as laser generator, laser cutting head, laser cutter frame, laser cutting system, laser lens, laser mirror, laser power supply, water chiller, air compressor, and other many CO2 laser CNC kits. CO2 laser machine usually uses CO2 gas to process non-metal materials such as wood, paper, leather, cloth, epoxy resin, acrylic, wool, plastic, rubber, ceramic tile, crystal, jade, bamboo, etc. While the auxiliary gases include nitrogen, helium, xenon, and hydrogen is also permitted.

Since CNC CO2 laser has high energy conversion efficiency of up to 25% and good stability, it can also cut some thin metal materials such as aluminum and brass. In addition, the CO2 laser power is optional. So you can choose a 40W CO2 laser cutter for sale, 50W wood laser machine, 60W acrylic laser cutting machine, 80W CO2 laser cutting and engraving machine, 100W laser engraver, 130W CNC CO2 laser cutting machine, 150W CO2 laser cutter, 300W wood cutting laser cutter, etc.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.