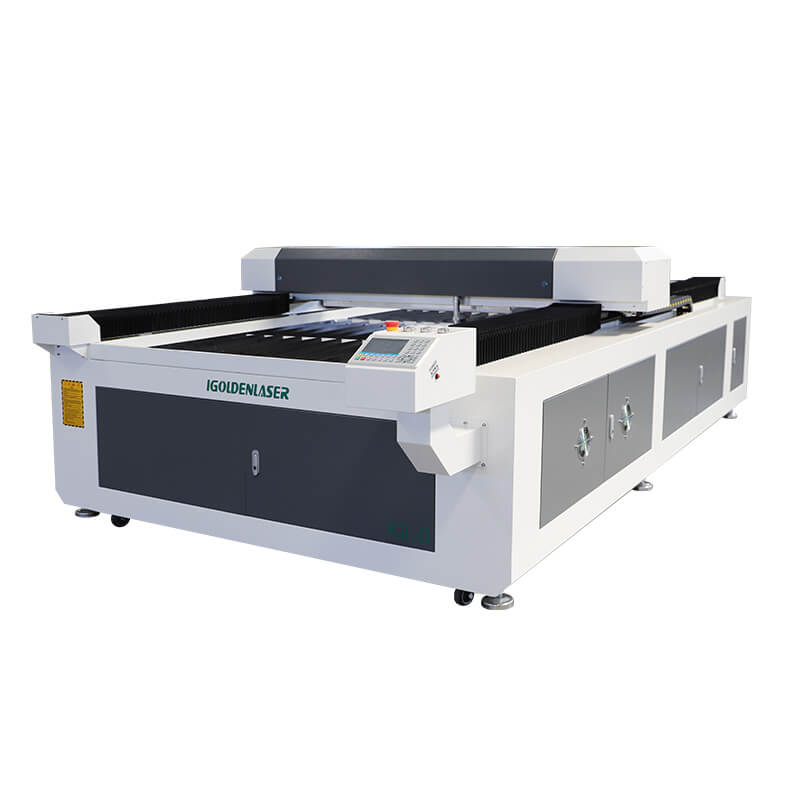

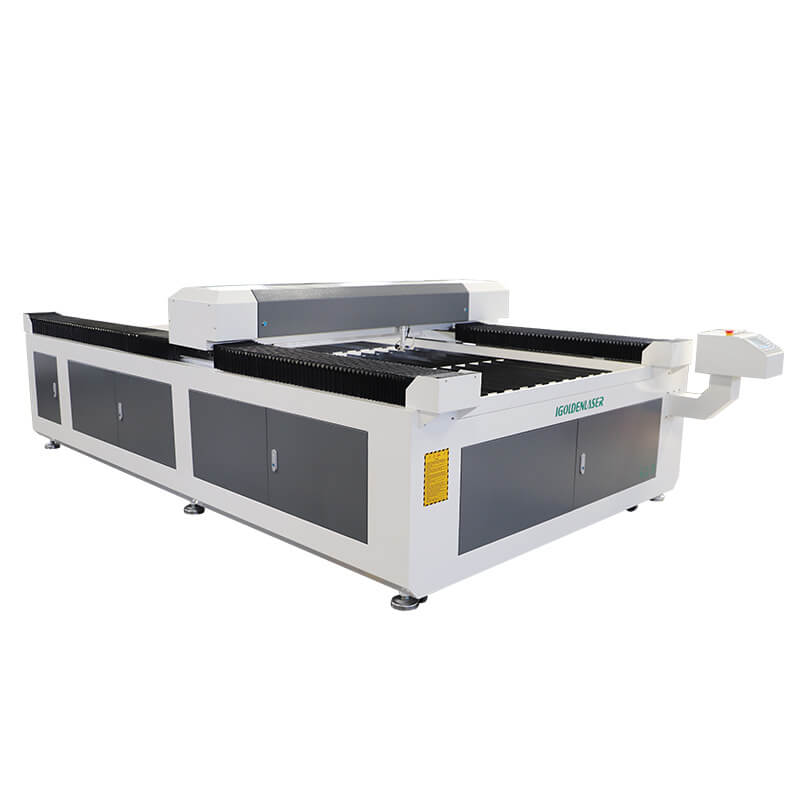

CO2 Laser Cutter Engraver

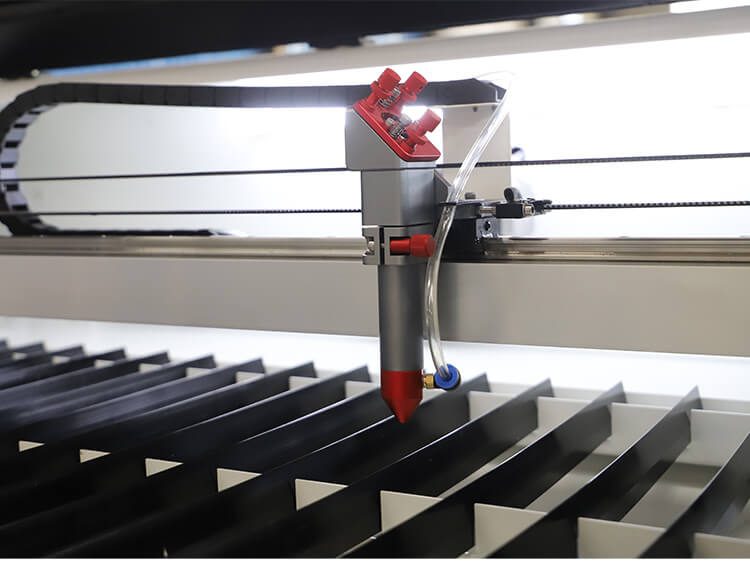

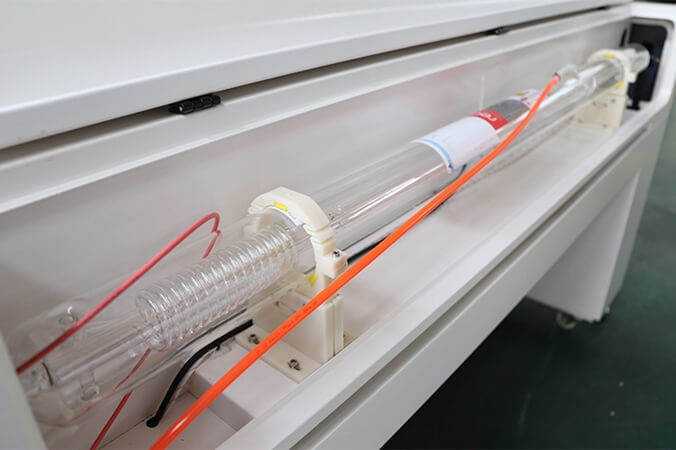

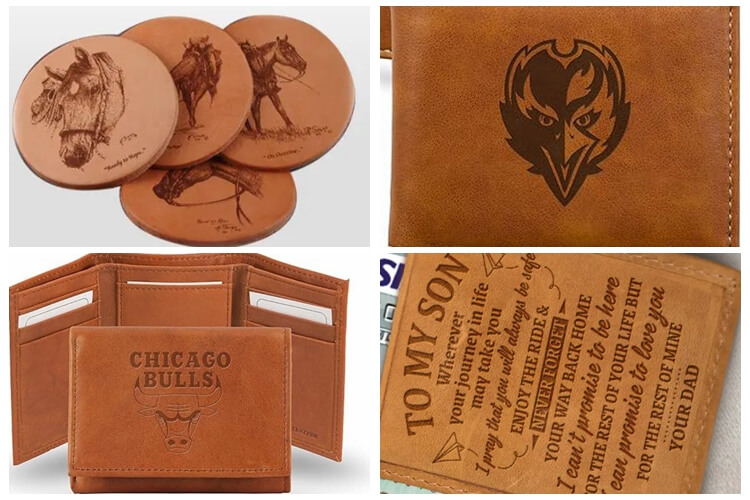

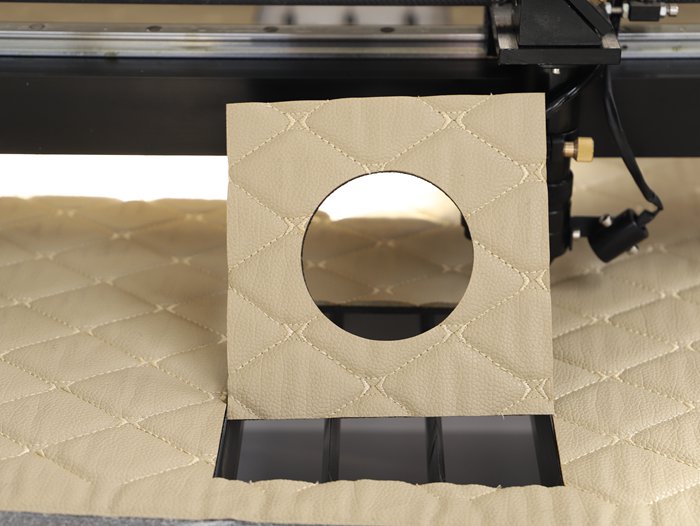

The CO2 laser cutting machine uses CO2 and other gas-particle as the laser medium and cuts objects. The CO2 laser cutter cuts the materials having the height in between 6mm to 20 mm. The higher the power can cut thicker materials. This laser cutting system can cut any solid materials such as acrylic, wood, paper, metals, plastic, and all other elements.Because CNC laser cutting makes parts with no tool force, many parts can be fabricated without expensive tooling and fixtures. Small features, sharp corners, and closely spaced features are all handled more easily by laser cutting than by conventional milling or punching.

CO2 Laser cutting machines can cut a wide variety of industrial materials of varying thickness to just about any shape. Quick, clean, accurate and adaptable, laser cutting is the preferred method for many businesses across a wide range of industries.

Depending on the power supply, there are a few types of CO2 Laser Cutter, including 40w CO2 Laser Cutter, 50W CO2 Laser Cutter, 60W CO2 laser Cutting Machine for Metal, and 100W CO2 Laser Cutter. The history of CO2 Laser Cutting Machine started from the nineteenth century; still, it’s popular in the market.

Reviews

There are no reviews yet.