Buyer Guide

CO2 Laser Cutting and Engraving Machine

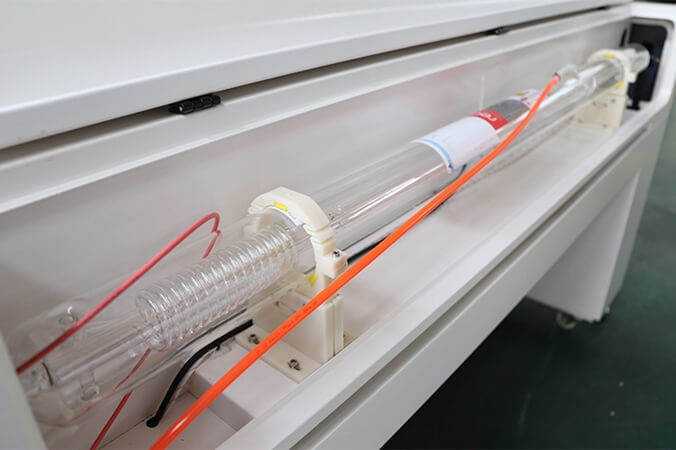

iGOLDEN laser engraving machine offers precise and aesthetical engraving and cutting of non-metal materials. The machine primarily uses CO2 gas along with electricity to produce a laser beam that can cut through or engrave most materials. A glass tube helps to focus laser beam onto the surface of the material, the beam goes down the tube and out the nozzle through focus lens. Once the beam exits the tube, it comes in contact with the surface of the material to be engraved. The speed can be controlled to ensure smooth and reliable engraving moreover the worktable it comes with is able to work with hard materials such as wood, acrylic etc. The machine comes with a control panel that displays the progress of the graphics.

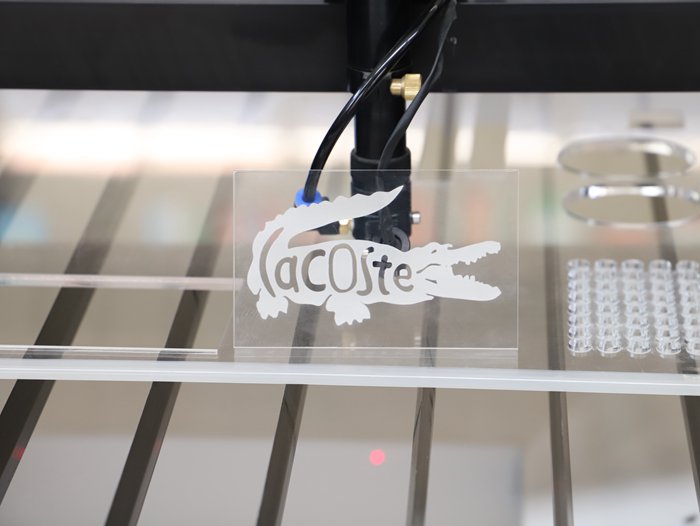

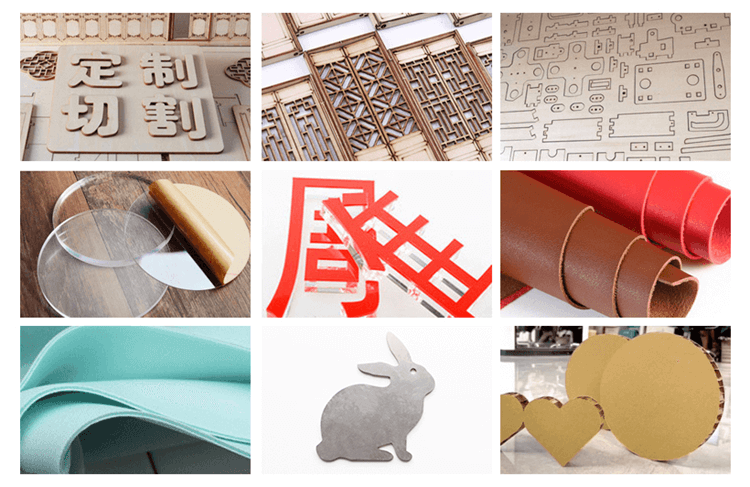

iGOLDEN laser engraving machine is widely used for fine engraving and cutting, hollow carving of acrylic, leather, paper, MDF, rubber, organic board, two-color board, wood board, bamboo products, glass, cloth, resin, plastic, rubber, ceramic tile, crystal, bamboo, organic glass and other non-metallic materials. The machine can cut and engrave various texts, graphics, images, trademarks, etc. CO2 laser engraving machine is suitable for both home and commercial purposes.

Features of Laser Engraving Machine

- Safety Protection: It will automatically cut off the power when the top access door is open, which protects the operator from any harm by the laser, increasing the safety, stability, and reliability of use and maintenance.

- Water Cooling Protection: To avoid any damage to the laser tube the machine will not fire the laser if the cooling water flow is not detected.

- Red-dot Positioning: the machine uses a red light indication method to achieve precise positioning of the laser beam.

- Breakpoint Continuous Engraving: In case of any power cut the machine will continue working from where it left off last .

- Worktime Preview Function: It can demonstrate real working time with accuracy up to the millisecond level, and also support dynamic display of machining path and coordinate points, real-time display and tracking of machining progress.

A CO2 laser engraver is an automatic etching system that uses a 10.6 μm wavelength CO2 laser beam to act on the surface of the substrate to vaporize the excess material to form pits, so as to make an engraved project. It is a carbon dioxide gas laser engraving cutting machine that uses the computer to control the X-Y console to drive the engraving head to move and control the switch as required. The CAD/CAM software generates a file from the designed pattern or text and stores it in the computer.

Laser Engraving Machine Applications

Compared with manual wood engraving machines and hand wood engraving tools, laser wood engraving machines have greatly improved the working efficiency for your laser engraving business plans. They can make the engraved surface more smooth and round, quickly reduce the temperature of the engraved non-metallic material, and reduce the deformation and internal stress of the engraved project. It can be widely used in the field of fine engraving of various non-metal materials. So far, you can meet laser engraved wood projects everywhere in the world, and it has become a common power tool in our daily work. Now, it is widely used in woodworking, sign making, advertising industry, crafts making, toys making, shoes, clothing, mold making, construction industry, printing industry, packaging industry, decorations, leather industry. The nonmetal laser engraver is suitable for woods (hard wood, soft wood, plywood, MDF, veneer, coniferous wood), leather, acrylic, textile, fabric, cardboard, rubber, paper, plastic, bamboo, ABS, PVC, fiber and composite materials.

How Many Types of Laser Engraving Machines?

Laser engraving machines are classified as laser wood engraver machines, metal engraver machines, leather engraver machines, stone engraver machines, fabric engraver machines, plastic engraver machines, rubber engraver machines, paper engraver machines, glass etching machines, acrylic engraver machines based on the engraving materials. Laser engraving systems are defined as CO2 laser systems, fiber laser systems (the best tool to engrave metal), and UV laser systems (the best tool to etch glass) based on the sources.

Laser engraving tables are divided into mini types, handheld types, compact types, desktop types, portable types, 2×3 engraving tables, 2×4 engraving tables, 4×4 engraving tables, 4×8 engraving tables, 5×10 engraving tables, large format engraving tables according to the working area. These kits are classified as home kits, hobby kits, commercial kits, industrial kits based on applications. These kits are defined as laser jewelry engravers, pen engravers, iPhone engravers, gun engravers, ring engravers, signage engravers, art engravers, logo engravers, cup engravers based on industries. If you are working for 3D engraving, the rotary engraver kit is the best solution.

How does a CO2 Laser Cutting Machine Work?

You may want to know how to laser cut leather, how to laser cut fabric at home, or how to laser engrave acrylic. But first, Co2 laser cutter how it works?

Laser machine tool lies in laser beams. CO2 laser machine uses a CO2 laser tube with a CNC system to irradiate the laser beam to the surface of the object. At the same time, the glass laser tube releases high energy heat to melt and evaporate the object surface to achieve CNC CO2 laser cutting and engraving. And in a CO2 laser engraving machine, light is produced when an electric current is passed through a gas-filled tube with mirrors at both ends. One mirror is fully reflective, while the other only lets some light through. Next, these mirrors direct the laser beam into the material to be cut. And the gas is usually a mixture of carbon dioxide, nitrogen, hydrogen, and helium.

In addition, CO2 laser beam is a very high-intensity beam of light. It is a kind of infrared ray with a single wavelength or color, which is invisible to the human eye. When the Co2 laser beam passes through the beam path from the resonator, its diameter is only about 3/4 of an inch. So, it may be reflected in different directions by many mirrors or “beam benders” before it is finally focused on the plate. And the focused CO2 laser beam passes through the nozzle hole before hitting the plate, as well as the compressed gas such as oxygen or nitrogen. Besides, higher CO2 laser power is for cutting and lower CO2 laser power is for engraving. Actually, the CO2 laser power is adjustable during operation. Laser power also affects the depth of CO2 laser engraving and the thickness of CO2 laser cutting.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.