Laser Knowledge

CO2 Laser Engraver & Metal Laser Cutter Machine

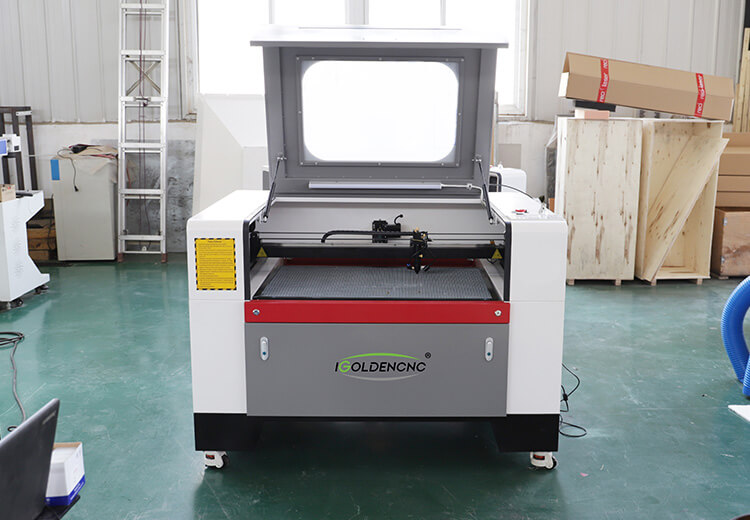

CO2 Laser Engraver

CO2 Laser Cutting for Wood and Nonmetal Solution

CO2 laser engraving and cutting machine series adopts international advanced DSP control technology, they have the high speed, high cutting accuracy and high stability, the quality and price ratio is very high. The main system can be commanded by U-disk without PC connection. It has the functions of imitative cutting, color separating cutting, non-stop cutting once off power, etc.Engraving and cutting of paper, fabric, plastic, non woven cloth in garment and toy industries, also inclusive of precise cutting to non-metal materials, like acrylic and MDF board in handbag, glove, mold, advertisements, decoration, electrical appliance and plastic industries.

130W/150W/220W CO2 Laser Mixed Laser Cutting Machine for Metal & Non Metal

This Co2 Laser etching machine is a mixed laser cutting machine uses co2 laser source to engraving and cutting metal and non-metal, such as glass, wood, acrylic, plastic, stainless steel, etc.

CO2 Laser Engraver Features

1. Adopting steel structure bed, the design is more scientific and the bed is more stable.

2. One machine with dual functions. It is able to cut both non-metal and thin metal materials such as stainless steel, carbon steel, acrylic and wood.

3. The high precision linear guide transmission ensures more steady of the cutting operation, thus maintaining high cutting precision and good stability.

4. The quality of the cutting section is good because it adopts the mechanical follow-up cutting through system. The cutting head follows the height of the plate, and the position of the cutting point remains unchanged, so that the cutting seam is flat and smooth.

5. Its cross beam uses high-strength aluminum alloy, which is lightweight, has small resonance, and operate more smooth.

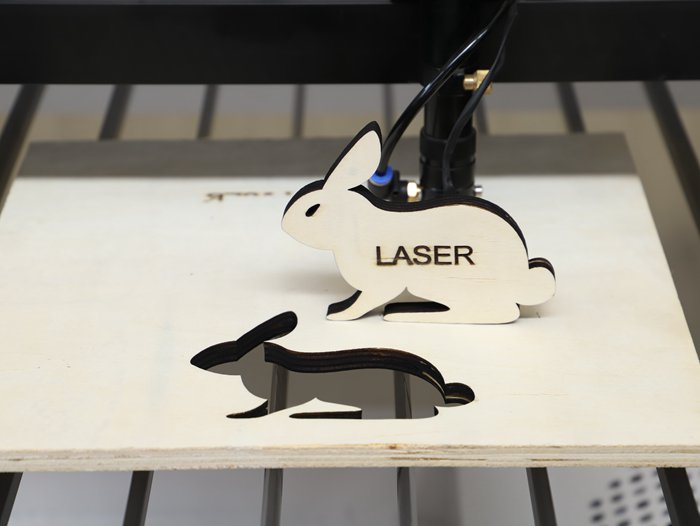

Laser Wood Cutting Machine On Sale With CO2 Laser Tube

Top rated 100W laser wood cutting machine with CO2 laser tube is the cheapest laser wood cutter kit with CNC controller for beginners to engrave & cut wood (softwood, hardwood, solid wood, MDF, plywood) for crafts, 3D puzzles, letters, earrings, panels, signs, logos, arts, gifts and more designs into different 2D/3D shapes & profiles.

Laser Wood Cutting Machine Features and Advantages

1. The laser wood cutting machine with 100W CO2 laser tube adopts more scientific design and high strength metal plate frame, which can increase the fuselage strength more than 40% to prevent the machine from distortion during long term work. In addition, this structure is very stable and not easy to be out of shape. The sound insulation effect is good.

2. Advanced Ruida 6442G control system for CNC wood laser cutter is the latest generation of laser engraving cutting control system, the control system hardware has better stability, better resistance to high pressure, anti-static properties of interference.

3. New-style high-efficiency RECI laser tube is adopted. Laser beam is more stable than the traditional type. Usage age is more than 10,000 hours.

4. Taiwan HIWIN square linear guide rail will be installed on X axis and Y axis to ensure the laser wood cutter works stably and precisely.

5. The CO2 laser wood cutting system adopts high quality professional square tube framework, with more than 40% higher fuselage strength than iron sheet structure. This design prevents the laser wood cutting machine from quivering, resonance and distortion during long term work.

6. Red dot position system is added in standard configuration, contributing to simple and precise working position.

7. The CNC wood laser cutting system adopts advanced LCD Screen + USB port + Offline Control, with professional motion control chip, which has the functions of consecutively high-speed curve cutting and the shortest path selection, which largely improves your working efficiency.

8. USB offline control system makes the wood laser cutter operation more convenient and faster.

9. Automatic up-down table for the wood laser cutter can be chosen for thick materials and high objects.

10. The cutting and engraving area is 1300x900mm for most of woodworking projects.

11. Unlike 3D printers, it requires no consumables.

Metal Laser Cutter Machine

Metal Laser Cutting Machine iGR-F

This sheet metal fiber laser cutter is an ideal entry level laser cutting machine for you to process the metal materials. With easy operation and simple maintenance, this machine can provide users powerful cutting ability and efficiency.In the cutting process of fiber laser for general metal materials, due to the fast cutting speed, the thermal deformation of the parts is small, and the dimensional accuracy of the cut parts mainly depends on the mechanical accuracy and control accuracy of the worktable of the laser cutting machine. In the fibre laser cutting process, the high-precision cutting device and control technology are used, and the dimensional accuracy can reach the highest level.

Metal Laser Cutting Machine Features

1. Intelligent automatic focusing laser head Automatic focusing mode of the laser head reduces human interference with a focusing speed of 10m/min and repeated positioning accuracy of 50um.

2. Aviation aluminum beam Aviation aluminum is corrosion resistant, lightweight and highly rigid, guaranteeing high speed laser cutting. Besides, it also guarantee the excellent cutting precision due to the perfect dynamic performance such as anti-twisting, anti-tilting and anti-deformation.

3. High quality thick wall carbon steel plate welding bed High strength machine bed is more stable and durable. After 600℃ stress relief annealing treatment, the machine bed has strong structural rigidity. The overall mechanical structure of the machine has small deformation, low vibration, ensure cutting accuracy.

4. Integrated large volume dust removal system The dust removal system can remove all the smoke generated from the cutting process with large air volume. This helps protect the operator’s health and the working environment.

5. Automatic lubrication system Automatic lubrication method saves more human labor, reduces maintenance time, and greatly improves work efficiency.

Dual Purpose Sheet and Tube Laser Cutting Machine Fiber Laser Cutter for Steel, Aluminum, Titanium, Copper

New metal sheet and tuber laser cutting machine is an ideal entry-level laser cutting machine without any high purchase cost or training cost. It has easy operation and simple maintenance. One machine integrates two functions, reducing the floor space and improving efficiency.Affordable 5×10 industrial fiber laser metal cutting machine for sale at cost price to cut both sheet metals and tubes all in one machine for metal fabrication.

Tube Fiber Laser Cutting Machine Advantages

- The tube laser cutting machine has fast cutting speed and good cutting quality. It will achieve a small slit, small deformation, and a smooth cutting surface.

- The working format is equipped with a pipe-cutting device. It can cut flat plates and round pipes. With stronger applicability, it can save the cutting process. The tube cutting laser machine is suitable for mass production, high work efficiency, and high stability.

- It has tube plate integrated laser cutting precision. So it is more suitable for precision parts processing and fine arts and crafts cutting.

- Laser equipment installed a focal length automatic tracking adjustment system. It can easily complete the distortion of material cutting.

- The whole laser cut machine adopts an imported servo motor and precision guide rail. It has high-precision cutting technology. It is stable and has a longer life. In the cutting, the pipe can highlight its advantages, exquisite cutting process, and precision.

co2 laser VS fiber laser engraver

co2 laser

A CO2 laser cutter is an automatic laser cutting machine that uses carbon dioxide light beam to engrave and cut wood, MDF, plywood, chipboard, dieboard, cardborad, acrylic, fabric, jeans, plastic, leather, paper, ABS, EPM, PE, PES, PUR, PVB, PVC, PUR, PMMA, PTFE and thin metals, which is widely used in industrial manufacturing applications, school education, small businesses, home business, small shop and home shop. It is composed of bed frame, cutting head, lens, mirror, generator, power supply, water chiller, control panel and CNC (Computer Numerical Controlled) system.

CO2 laser is a pulsed wave beam in which carbon dioxide gas obtains continuous wave or high output area in the infrared of the medium. The wavelength is 10.6μm. It is a light source used for rapid prototyping. High-power lasers are used for cutting and drilling. The medium power output is used for engraving. Since the output wavelength is easily absorbed by water, it is also widely used in medical treatment.

A CO2 laser generator is a gas laser generator with CO2 gas as the working material. The discharge tube is usually made of glass or quartz material, filled with CO2 gas and other auxiliary gases (mainly helium and nitrogen, and usually a small amount of hydrogen or xenon). The electrode is generally a hollow nickel cylinder and a resonant cavity. One end is a gold-plated total reflection mirror, and the other end is a partial reflection mirror polished with germanium or gallium arsenide. When a high voltage (usually DC or low-frequency AC) is applied to the electrode, a glow discharge is generated in the discharge tube, and there is a laser output at one end of the germanium mirror, and its wavelength is in the mid-infrared band near 10.6 microns.

Carbon dioxide laser generators are usually made of hard glass, and generally adopt a layered sleeve structure. The innermost layer is the discharge tube, the second layer is the water-cooled casing, and the outermost layer is the gas storage tube. The diameter of the discharge tube of the carbon dioxide laser generator is larger than that of the He-Ne laser tube. Generally speaking, the thickness of the discharge tube has no effect on the output power, mainly considering the diffraction effect caused by the size of the light spot, which should be determined according to the tube length. The longer tube is thicker, and the shorter tube is thinner. The length of the discharge tube is proportional to the output power. Within a certain length range, the output power per meter of discharge tube length increases with the total length. The purpose of adding a water cooling jacket is to cool the working gas and stabilize the output power. The discharge tube is connected to the gas storage tube at both ends, that is, one end of the gas storage tube has a small hole communicating with the discharge tube, and the other end communicates with the discharge tube through the spiral return tube, so that the gas can circulate in the discharge tube and the gas storage tube flow, the gas in the discharge tube is exchanged at any time.

A CO2 laser tube is a sealed glass tube composed of hard glass, a resonant cavity and electrodes that produces a light beam for cutting and engraving materials.

fiber laser engraver

Laser cutting machine is an automatic cutter with a CNC controller kit that combines CAD/CAM software to cut through metals, metalloids and nonmetals with a CO2 or FIBER laser beam, as well as cut custom shapes, contours, and holes out of sheets and profiles to create personalized parts, signs, tags, decorations, arts, crafts, gifts, jewelries, lamps, and puzzles for hobby uses and industrial commercial uses.

Laser cutter is an automated cutting tool kit that uses a laser beam together with a smart digital cutting system to cut out patterns on metals (steel, copper, brass, aluminum, titanium, gold, silver, alloy, iron), acrylic, rubber, wood, plywood, MDF, plastic, leather, paper, foam, textile and fabric. A laser kit consists of machine base and frame, CNC controller, generator, power supply, tube, head, lens, mirror, water chiller, stepper motor or servo motor, gas cylinder, air compressor, gas storage tank, air cooling filer, dust extractor, dryer and software.

Laser cutting system is an organized collection of parts that are integrated to accomplish precision cuts for industrial manufacturing, commercial use, education, training, small business, home business, small shop, and home shop. It is a flexible cutting system compared to manual and mechanical cutting tools. It can cut a variety of materials in varying thicknesses and there is no limit to the shapes you can get. It is fast to program and any changes can be applied at any stage of manufacturing at almost no additional cost and time. It features with high precision, excellent trimming quality and no deformation of parts. It is the best solution for modularization and automation in the manufacturing cycle.

How Does A Laser Beam Cutting Machine Work?

Laser beam is a type of light from the transition of atoms (molecules or ions). However, it is different from ordinary light in that it depends on spontaneous radiation only for a very short period of time. The subsequent process is completely determined by the excitation radiation, so it has a very pure color, almost no divergence direction, and extremely high luminous intensity, and high coherence.

It is an automated process that uses high-power and high-density energy from a focused light beam to melt and vaporize metal, wood, acrylic, plastic, fabric, leather, foam, and other materials, resulting in a precision kerf.

With the CNC controller, the generator outputs a high-frequency to make a beam with a certain frequency and pulse width. The beam is transmitted and reflected through the optical path and focused by the focusing lens group. A tiny, high-energy-density light spot is formed on the surface of the part, the focal point is located near the surface to be cut, and the material melts or vaporizes at an instant high temperature. Each pulse shoots a small hole in the substrate. With the computer numerical controller, the head and the substrate perform continuous relative movement and dotting according to the designed file, so as to cut the substrate into the desired shape. The technological parameters (cutting speed, power, gas pressure) and movement trajectory during slitting are controlled by the CNC system, and the slag at the slit is blown off by the auxiliary gas with a certain pressure. The beam emitted by the generator is focused by the optical path system into a beam of high-power density. The beam is irradiated onto the surface of the part to bring the part to a melting point or boiling point, while the high-pressure gas coaxial with the beam blows away the molten or vaporized material. As the beam moves relative to the part, the material is slit finally, thereby achieving the purpose of cutting. Different powers can cut different projects with different thickness. Generally speaking, higher power for thicker part. You should make the appropriate choice according to your requirements.

What to do with a Laser Cutter Engraver?

If I buy a laser cutter, can CNC laser cutter engraver do what CNC laser designs? Blue Elephant provides a variety of CNC laser cutting engraving equipment. All these best laser machines can help you realize your CNC laser solutions.

1. Laser cut and engrave wood wooden signs, letters, jigsaw puzzles, splicing decorations, wooden door front, wood chair, wood desk, bookshelves, cabinets, cutlery, plywood toys, decorations, handicrafts, paintings, picture frames, screen, statues, wooden boxes, jewelry boxes, etc.

2. Laser cut acrylic acrylic wine rack, LED acrylic sign, acrylic phone stand, acrylic photograph, acrylic lace earrings, acrylic kids night light, acrylic numbers, acrylic nameplate, acrylic decorations,acrylic cup, acrylic box, acrylic shelf, etc.

3. Laser cut metal Stainless steel sheet cutting, aluminum sheet metal laser cutting , carbon steel pipe laser cut, galvanized sheet cutting, copper tube laser cut, metal wall art, metal privacy screen, metal candle holder, metal key hanger, metal entry gate custom, metal wall sconce, metal art railings, laser cut steel console, metal lighting project, Stainless steel cutlery, metal chairs and tables, etc.

Buyer’s Guide

When buying a laser cutter, it’s important to focus on technical features to ensure that the machine meets your needs. Key technical features to consider include power, cutting area, resolution, and software compatibility. Laser power determines the type and thickness of materials the cutter can handle, while the cutting area refers to the size of the working area. Resolution determines the level of detail and precision the cutter can achieve. It’s also important to ensure that the cutter is compatible with the software you plan to use. Price is another important factor to consider when buying a laser cutting machine. The cost can vary depending on its technical specifications and the brand. It’s important to balance cost with the machine’s capabilities and reliability to ensure that you are getting good value for your money. By considering these technical features, you can make an informed decision when choosing a laser cutter kit & cutting system that will meet your specific needs and requirements.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.