Buyer Guide

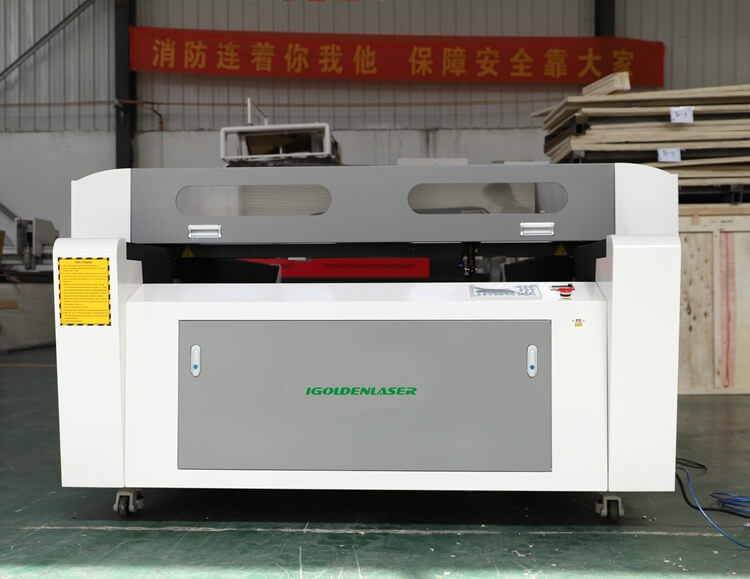

Co2 Wood Laser Cutting Machine

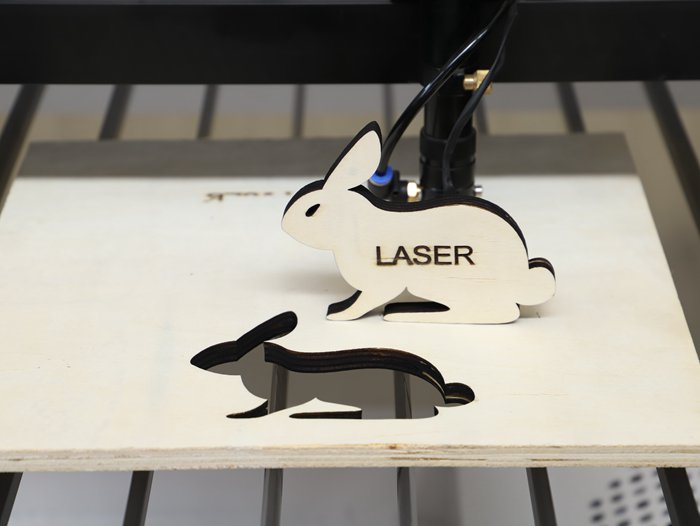

CO2 wood laser cutting machine can quickly cut and shape according to the pattern

Automatic layout function can also greatly improve material utilization

Reduce material waste

Under the high-precision CO2 wood laser cutting machine

Completed dozens of fine wooden parts, with smooth edges and no burrs

Co2 Wood Laser Cutting Machine

- Hardwood: Wood laser cutting has good adaptability to hardwood. Common types of hardwood such as oak, walnut, and cherry wood can be accurately cut by CO2 laser cutting machines. CO2 laser cutting can provide fine cuts and engravings on these hardwoods.

- Softwood: Wood laser cutting is also suitable for softwood, such as pine, spruce, and cedar. Laser cutting can cut softwood quickly and can achieve detailed cuts.

- Plywood: CO2 laser cutting machines are efficient at cutting plywood, a material made from multiple layers of wood veneers glued together. Laser cutting can create complex designs and holes in plywood and is highly adaptable. Commonly used in furniture, construction, and craft manufacturing.

- MDF: Plywood laser cutters are ideal for processing MDF, a high-density board made of wood fiber and synthetic resin. Laser cutting enables smooth cut edges on MDF without the need for further processing.

Large Size CO2 laser cutting machine, the standard worktable size is 1300*2500, equip with 150w/180w/260w/300w laser tube, satified the engraving and cutting requirements of large plate such as S.S sheet, C.S sheet, wood sheet, acrylic sheet and so on.

Advantages of CO2 wood laser cutting machine processing wood products

◆Transportation of catties becomes popular-laser technology for non-contact processing, no tool wear and no damage to materials.

◆Unrestricted and unrestrained-software control, graphics are not restricted, can complete the processing of various complex graphics.

◆Make the best use of the material-the automatic typesetting function can maximize the utilization of materials.

◆Exquisitely crafted-high precision, beautiful cuts, more delicate effects, to meet the production technology needs of wood products.

General purpose laser cutting machine

1. The functional characteristics of general laser cutting machine

◆Integrate carving and cutting

◆High-speed smooth interpolation motion algorithm

◆Real-time dynamic display and tracking of processing trajectory

◆Continuous engraving after power failure, millisecond-level working hours preview

◆Spot size trajectory compensation function

2. Process application of general laser cutting machine

General laser cutting machine is suitable for wood products, paper, leather, cloth, plexiglass, epoxy resin, acrylic, wool, plastic, rubber, bamboo products, clothing fabrics, leather goods, mobile phone accessories, stickers, clothing hot drilling, plastics Non-metallic materials such as nozzles, mobile phone protective films, jade ware, etc.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.