Buyer Guide

Customized Metal Sheet Fiber Laser Cutting Machine

In the world of metal fabrication, precision and efficiency are paramount. Whether you’re a professional metalworker or a hobbyist looking to explore the possibilities of metal cutting, investing in a customized metal sheet fiber laser cutting machine can revolutionize your craft.These cutting-edge machines utilize advanced laser technology to deliver precise and intricate cuts on various types of metal sheets.

Customized Metal Sheet Fiber Laser Cutting Machine

Customized metal sheet fiber laser cutting machines are designed to meet the specific needs and requirements of metal fabricators. These machines utilize a high-powered fiber laser beam to cut through metal sheets with incredible precision and speed. The laser beam is focused onto the surface of the metal sheet, melting and vaporizing the material along the cutting path. The result is a clean, smooth, and accurate cut that requires minimal post-processing.

The fiber laser cutting machine can do flat plate cutting, can also do inclined angle cutting production and processing, and the edge is neat and smooth. It is suitable for high-precision cutting production and processing such as metal sheets. It is suitable for cutting stainless steel plate, carbon steel, carbon steel, aluminum alloy profile and other metal plate materials and pipe fittings.

Metal Sheet Fiber Laser Cutting Machine Features

- Fiber laser cutting speed is fast, low operation and maintenance cost, and easy to learn.

- The machine adopts the dynamic dragon door structure, gear rack and linear guide, and the transmission is stable, and the precision is high.

- The machine tool and the beam pass high temperature, precision gantry, can maintain high strength, high precision, and long-term work is not deformable.

- X, Y, Z axis use imported servo motors, high precision, high speed, large torque, high inertia, and stable and durable. The high speed and acceleration of the whole machine are guaranteed.

- The special CNC system of Shanghai Bochu fiber laser cutting machine based on Windows operating system is integrated with laser cutting control dedicated function modules, powerful, human-machine interface, simple operation.

- Mobile gantry structural machine tool, the whole outer surrounding structure, can maintain a long time, good stability, safety; automatic switching workbench, equipment can be processed on the side, convenient and fast, good compatibility, strong stability , More convenient maintenance, and more powerful cutting functions.

Configuration Introduction

High-speed exchange table

High-speed parallel exchange table design, dual working table exchange at the same time, stable and reliable transmission mode. Fast, shorten the exchange time, save the loading and unloading auxiliary time. Exchange motor controlled by frequency converter, can finish the table exchange within 15S.

New “core” intelligent system

New generation of CNC system, more flexible in operation. Imported mature system and servo motors, integrated independently developed special laser cutting system. Operation system provides a rich and friendly human-computer interaction interface, which is a bridge for communication and interaction between machines and humans.

Excellent performance

The table is designed with a thin plate tightening mechanism to improve the stability of the plate cutting process. Using deadly guide rails, racks, motors, reducers, etc. as transmission mechanism components, the positioning accuracy of the machine tool is ±0.01mm

Energy saving and environmental protection

High conversion efficiency, less processing waste, automatic collection of smoke and dust, protecting the environment and human health

Auto focus laser cutting head

Automatic focusing

Customized Metal Sheet Fiber Laser Cutting Machines Laser head with auto focus function, can adjust the focus automatically, don’t need to adjust by manual, The software can change different focusing lenses automatically and quickly to meet the cutting of different thickness plates, Simple, convenient, fast and accurate in operation.

Large adjustment range

The accuracy is 0.01mm, suitable for different types of 0-20mm plates.

Long life span

Full-circle water cooling around the focusing component, realizing high-power, small-volume and long-term cutting No heat, no fog, improve the life of laser cutting head.

Aerospace aluminum gantry

The aerospace aluminum is manufactured under aerospace standards. After artificial aging and solution treatment, it is finished. Hardness can reach to T6, and it has the characteristics of good toughness and ductility.

Light in weight, convenient for high-speed movement during processing, and is highly flexible. It can greatly increase the processing speed when the accuracy is met.

Plate welding bed design

The bed adopts an open-web integral profile welding structure that has been verified and verified by CAE analysis. High temperature annealing and natural aging are used to eliminate welding stress, prevent deformation, reduce vibration, and ensure cutting accuracy

Application

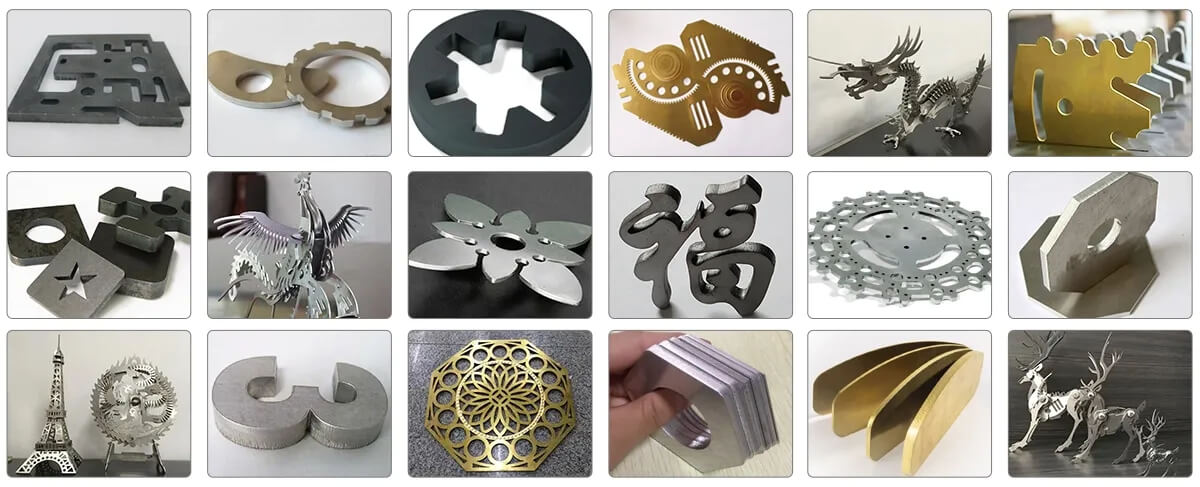

Customized Metal Sheet Fiber Laser Cutting Machines is widely used in: electric electrical, automotive manufacturing, mechanical equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising logo, automotive decoration, precision parts, chassis cabinets, furniture, lighting, process ornaments and other industries.

Choosing a Customized Metal Sheet Fiber Laser Cutting Machine

When selecting a customized metal sheet fiber laser cutting machine, there are several factors to consider:

1. Power and Cutting Capacity

The power of the laser source determines the cutting capacity of the machine. Consider the thickness and type of metal sheets you will be working with and choose a machine that can handle your requirements. Higher power machines can cut through thicker materials but may come at a higher cost.

2. Bed Size and Work Area

The bed size and work area of the machine should accommodate the size of your metal sheets and the complexity of your projects. Ensure that the machine offers enough space for maneuvering and positioning the sheets comfortably.

3. Software and Control System

The software and control system of the machine play a crucial role in its usability and functionality. Look for a machine that offers user-friendly software with intuitive design tools and a control system that allows for easy operation and adjustment.

4. Maintenance and Support

Consider the maintenance requirements of the machine and the availability of technical support. Regular maintenance ensures the longevity and optimal performance of your machine, while reliable technical support can assist you in case of any issues or questions.

5. Budget

Last but not least, consider your budget when choosing a customized metal sheet fiber laser cutting machine. While these machines can be a significant investment, they offer long-term benefits in terms of productivity and quality. Determine your budget range and find a machine that offers the best value for your investment.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.