Buyer Guide

Affordable Desktop Laser Engraver Cutting Machine

A desktop laser cutting machine, also known as a desktop laser cutter or a benchtop laser cutter, is a compact and versatile tool used for cutting various materials with the precision of a laser beam. It’s designed to be used on a desktop or workbench, making it suitable for small-scale projects and personal use.

Desktop laser cutting machines typically use either CO2 lasers or fiber lasers. CO2 lasers are better suited for cutting non-metal materials like wood, acrylic, and certain plastics, while fiber lasers are more suitable for cutting metals like steel, aluminum, and brass.

The cutting area of a desktop laser cutter is smaller compared to industrial-grade machines. The size varies, but it’s generally in the range of a few square inches to a few square feet. Consider the size of your intended projects and ensure that the cutting area accommodates your needs.

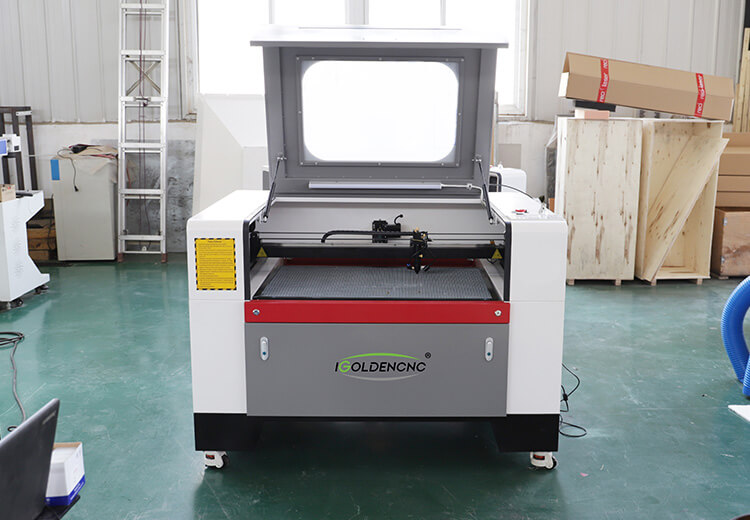

CO2 Desktop Laser Engraving Cutting Machine

Desktop laser engraving cutting machine available in different power levels, typically measured in watts. Higher wattage machines can cut through thicker and harder materials. Precision is measured in terms of the minimum spot size the laser can achieve. A smaller spot size allows for finer details and intricate cuts.

CO2 Desktop laser cutting machine can work with a wide range of materials, including wood, acrylic, leather, fabric, paper, cardboard, certain plastics, and some metals. However, not all machines are compatible with all materials, so make sure to check the specifications of the specific machine you’re considering.

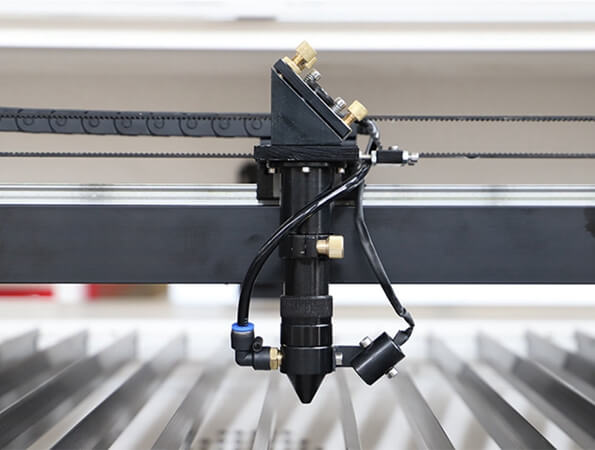

Desktop laser engraving and cutting machine is a device that uses a high-powered laser beam to etch or engrave various materials such as wood, acrylic, leather, and plastics, and even cut through thinner materials. It works by directing the laser beam through a series of mirrors and lenses, which focus the beam to a precise point on the material being engraved or cut. The focused beam vaporizes or melts away the material, creating a desired pattern or shape.

Affordable Laser Cutting Machine

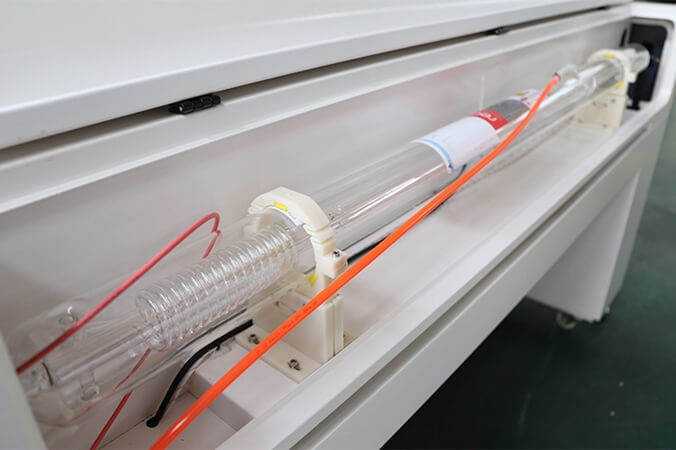

Carbon dioxide laser is a gas molecular laser, the working substance is CO2 gas, auxiliary gases are nitrogen helium, xenon and hydrogen, etc., because the energy conversion efficiency of this laser is as high as 25%, it is often a high-power output laser, carbon dioxide laser wavelength 10.6 microns, is impossible to see infrared light, good stability, widely used.

Using the most advanced DSP control technology in the world, the first industry-leading continuous and fast curve cutting function and the shortest machining path optimization function, greatly improving work efficiency. Automatic light attenuation compensation for the whole process of engraving, to ensure that different areas of cutting to maintain consistency, fast cutting control software design and high-speed motion buffer function, can improve production efficiency.

CO2 lasers are used to engrave text & patterns and cut shapes & contours in clothing, fashion, garment, shoes, bags, toys, embroidery, electronic appliances, molds, models, arts, crafts, advertising, decorations, packaging, and printing.

Here are some key points about Desktop laser engraving cutting machine :

- Laser Source: These machines utilize a CO2 laser tube as the energy source. CO2 lasers produce a high-intensity beam at a wavelength of around 10.6 micrometers, which is well-suited for engraving and cutting a variety of non-metallic materials.

- Engraving: CO2 laser engraving machines use the laser beam to vaporize or remove the surface layer of a material, creating detailed and precise engravings. They can engrave various materials such as wood, acrylic, leather, fabric, paper, glass, stone, and certain plastics.

- Cutting: CO2 laser cutting machines use the laser beam to melt or vaporize the material along a predetermined cutting path. This allows for precise and clean cuts in materials like acrylic, wood, plywood, MDF, rubber, fabric, leather, and certain plastics. However, they are not suitable for cutting metals.

- Working Area and Table: co2 laser engraver come in various sizes, with different working areas to accommodate different material sizes and project requirements. The machine usually has a table or platform where the material is placed for engraving or cutting.

- Precision and Speed: co2 laser engraver offer excellent precision and speed. The focused laser beam allows for intricate and detailed designs, while the high-speed cutting capabilities enable efficient production. The precision and speed can be adjusted based on the material and desired outcome.

- Software and Control: CO2 laser engraving cutting machines are typically controlled by specialized software that allows users to design or import graphics, adjust settings, and create cutting or engraving paths. The software often supports vector-based file formats such as SVG, AI, DXF, and others.

- Material Compatibility: co2 laser engraver can work with a wide range of non-metallic materials. In addition to the materials mentioned earlier, they can also engrave or cut materials like cork, rubber, foam, paperboard, ceramic, and more. However, materials with high reflectivity, such as mirrors or certain metals, are not suitable for CO2 lasers.

- Safety Features: Safety is an important aspect when using 40w co2 laser engraver. They usually feature protective enclosures with safety interlocks to prevent accidental exposure to the laser beam. Additional safety measures may include laser power control, ventilation systems to remove fumes, and warning indicators.

iGOLDENCNC is the world-leading laser equipment manufacturer and service provider with a worldwide sales and service network and a broad network. Product resources guarantee that we can provide the most advanced laser technology and professional customer service. Over the past three years, we have provided a variety of cutting solutions for a wide range of industries, 2 years warranty is the best guarantee.

A CO2 laser cutting machine is an automated smart cutting tool kit that uses a glass laser tube to produce light beam, and works with a numerical control system to irradiate the beam to the surface of the object, and at the same time release high energy to melt and evaporate the surface of the object, thereby realizing the plan of cutting and engraving. The beam is a column of very high intensity light, of a single wavelength, or color. In the case of a typical carbon dioxide laser, that wavelength is in the Infra-Red part of the light spectrum, so it is invisible to the human eye.

The beam is only about 3/4 of an inch in diameter as it travels from the resonator, which creates the beam, through the machine’s beam path. It may be bounced in different directions by a number of mirrors, or “beam benders”, before it is finally focused onto the plate. The focused beam goes through the bore of a nozzle right before it hits the plate. Also flowing through that nozzle bore is a compressed gas, such as Oxygen or Nitrogen. Generally speaking, higher power is used for cutting, lower power is used for engraving. The power is adjustable during operation. Turn it down for engraving and turn it up for cutting. The level of power will also affect the depth of engraving and the thickness of cutting.

Desktop fiber Laser Cutting Machine

Desktop fiber laser cutting machin iGR-F

This desktop laser cutter is an ideal entry level laser cutting machine for you to process the metal materials. With easy operation and simple maintenance, this machine can provide users powerful cutting ability and efficiency.In the cutting process of fiber laser for general metal materials, due to the fast cutting speed, the thermal deformation of the parts is small, and the dimensional accuracy of the cut parts mainly depends on the mechanical accuracy and control accuracy of the worktable of the laser cutting machine. In the fibre laser cutting process, the high-precision cutting device and control technology are used, and the dimensional accuracy can reach the highest level.

Desktop Laser Cutting Machine Features

1. Intelligent automatic focusing laser head Automatic focusing mode of the laser head reduces human interference with a focusing speed of 10m/min and repeated positioning accuracy of 50um.

2. Aviation aluminum beam Aviation aluminum is corrosion resistant, lightweight and highly rigid, guaranteeing high speed laser cutting. Besides, it also guarantee the excellent cutting precision due to the perfect dynamic performance such as anti-twisting, anti-tilting and anti-deformation.

3. High quality thick wall carbon steel plate welding bed High strength machine bed is more stable and durable. After 600℃ stress relief annealing treatment, the machine bed has strong structural rigidity. The overall mechanical structure of the machine has small deformation, low vibration, ensure cutting accuracy.

4. Integrated large volume dust removal system The dust removal system can remove all the smoke generated from the cutting process with large air volume. This helps protect the operator’s health and the working environment.

5. Automatic lubrication system Automatic lubrication method saves more human labor, reduces maintenance time, and greatly improves work efficiency.

Desktop laser cutter Price and Budget

Desktop laser cutters come in a wide range of prices, depending on their capabilities and features. Consider your budget and the level of functionality you require for your specific projects.

Affordable Laser Cutting Machine Buyer’s Guide

When buying a laser cutter, it’s important to focus on technical features to ensure that the machine meets your needs. Key technical features to consider include power, cutting area, resolution, and software compatibility. Laser power determines the type and thickness of materials the cutter can handle, while the cutting area refers to the size of the working area. Resolution determines the level of detail and precision the cutter can achieve. It’s also important to ensure that the cutter is compatible with the software you plan to use. Price is another important factor to consider when buying a laser cutting machine. The cost can vary depending on its technical specifications and the brand. It’s important to balance cost with the machine’s capabilities and reliability to ensure that you are getting good value for your money. By considering these technical features, you can make an informed decision when choosing a laser cutter kit & cutting system that will meet your specific needs and requirements.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.