Buyer Guide

Fiber Laser Cutting Machine for Cut Metal Signs

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

A fiber laser cutting machine is an automatic precision metal cutting system that uses a CNC controller to drive a 1064nm laser beam to cut along the tool path generated by the CAD/CAM software to get clean and smooth metal cuts, which is a fine cutting tool for sheet metals, metal tubes, bars and straps with the ability to cut both flat and beveled metal shapes and profiles. Featuring a robotic arm, it can even perform personalized 3D metal cutting. Fiber lasers can cut metals from 1mm to 200mm with powers ranging from 1,000W to 60,000W at a maximum speed of over 120m/min.

Laser Cut Metal Signs

Laser cutting allows for extremely accurate cuts and intricate designs, resulting in high-quality metal signs with fine details and clean edges.Laser cutting produces precise cuts with minimal heat-affected zones, resulting in clean and smooth edges. This eliminates the need for additional finishing processes in many cases.Laser cutting is a fast and efficient method, allowing for quick production of metal signs. It is ideal for both small-scale and large-scale manufacturing, making it suitable for various projects.

Speed & Thickness

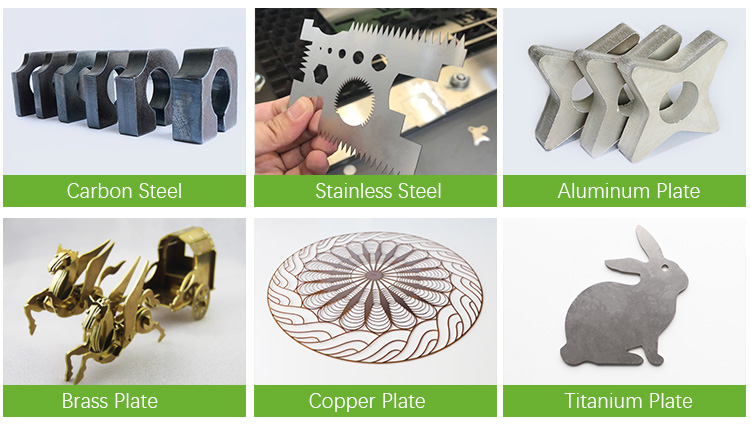

How thick of metal can a fiber laser cut through? What is the maximum speed? A fiber laser cutter comes with the ability to cut various thicknesses of different types of metals and alloys, working with gases such as oxygen, nitrogen or air to get clean and smooth cuts. Every brand of laser generator features with its own unique pros and cons to cut metals. In the case of the same generator, different powers will result in different maximum metal cutting thicknesses and speeds. Laser generators from different brands also vary in the accuracy and quality of their cuts. In comparison, the precision of IPG fiber laser is better than that of Raycus, MAX and RECI, and the speed is faster, but the price is also higher.

Custom Laser Cut Metal Signs

A fiber laser cutting machine is a type of laser cutting equipment specifically designed for cutting metal materials. It utilizes a fiber laser source to generate a highly concentrated beam of light that can cut through various types of metals with high precision and speed.

Working Principle

A fiber laser cutter uses a generator with the CNC control system to dope the pump material into the optical fiber, and the laser of a specific wavelength emitted by the semiconductor laser is coupled to make the optical fiber generate beam. Then, the machine converges the beam into a small diameter spot to form a beam of high energy density and extremely bright light, which acts on the metal to be cut, which causes the temperature of the metal at the irradiation point to be sharp it rises and reaches the vaporization temperature instantaneously, causing evaporation and forming holes. And the machine uses this as the starting point, according to the shape requirements of the part to be cut, the beam and the part are moved relative to each other according to a certain trajectory to form a slit. At the same time, the auxiliary gas blowing device is used to remove the slag.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.