Buyer Guide

Fiber Laser Metal Tube Cutting Machine

A fiber laser tube cutting machine is a type of industrial equipment used for precision cutting of metal tubes and pipes. It utilizes a high-powered fiber laser to generate a focused beam of light that can cut through various materials with great accuracy and speed.

The comprehensive solutions to tube laser cutting machines are here! Almost all tube types and wide applicable tube sizes of Bodor tube laser cutters ensure that you can benefit most from the metal tube laser cutting technologies.

Metal Tube Cutting Machine

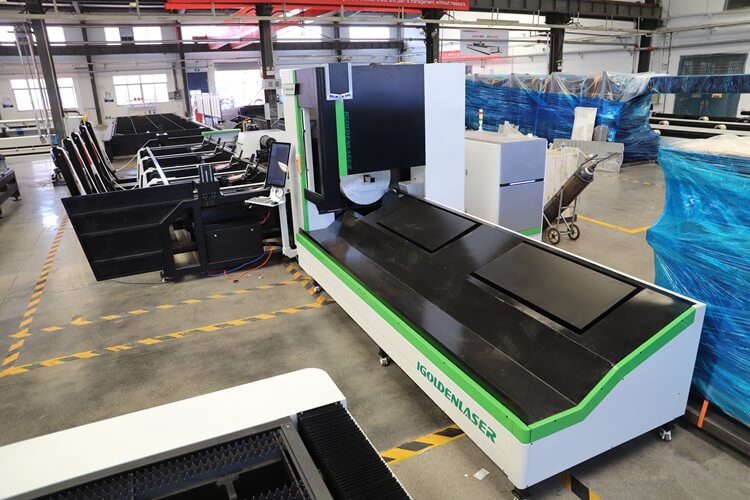

A tube fiber laser cutting machine is a type of laser cutting equipment designed to cut various types of metal tubes and pipes with high precision and speed. The T series has two specifications, 6016 model and 6024 model. The 6016 model can cut round and square tubes with a length of 6 meters and a max. diameter of 100 mm. The 6024 model can cut round and square tubes with a length of 6 meters and a max. diameter of 240 mm. . IGOLDENLASER continuously optimizes the appearance, structure and configuration of the T series according to market customer feedback, and strives to provide each customer with a high-performance, cost-effective laser cutting machine that meets the processing needs.

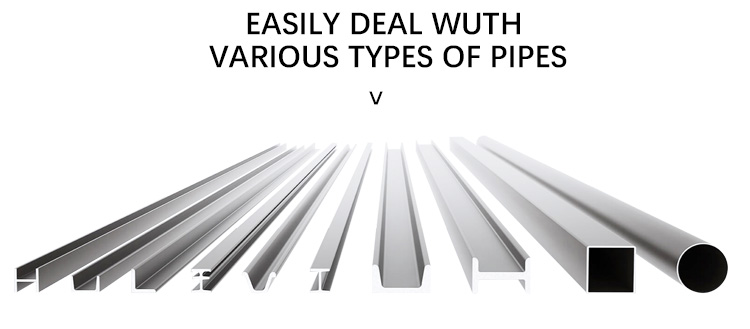

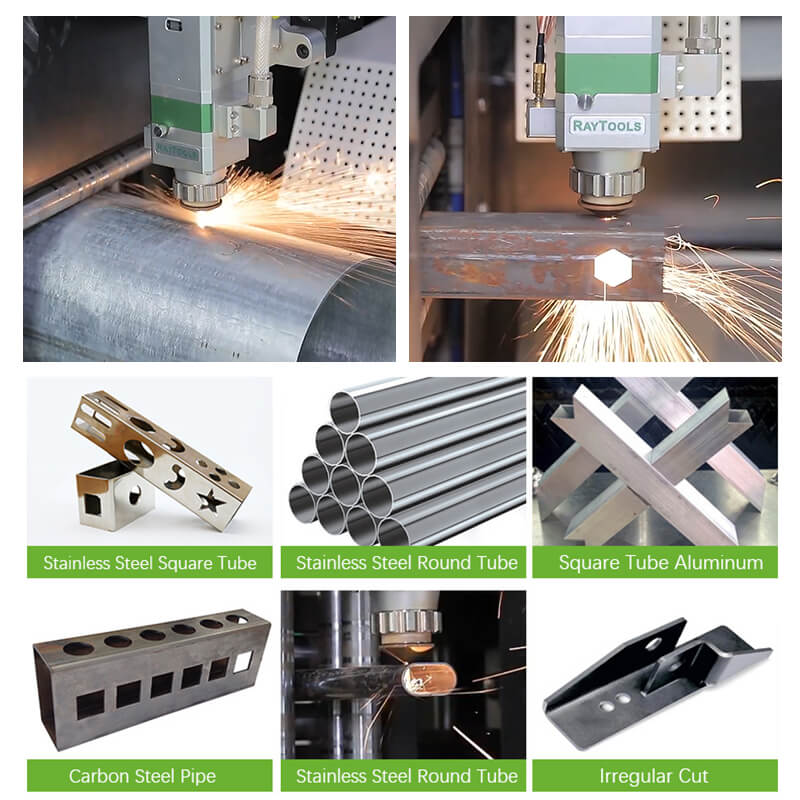

Metal tube laser cutting machine can be used to cut all kinds of metal shapes such as round tubes, square tubes, and special-shaped tubes. The newly upgraded metal pipe laser cutting machine production equipment not only achieves automatic production and processing, but also improves the limitations of traditional laser cutting, saving time and effort, reducing costs, faster and more accurate, and can achieve pipe punching and cutting。

No Waste of Material

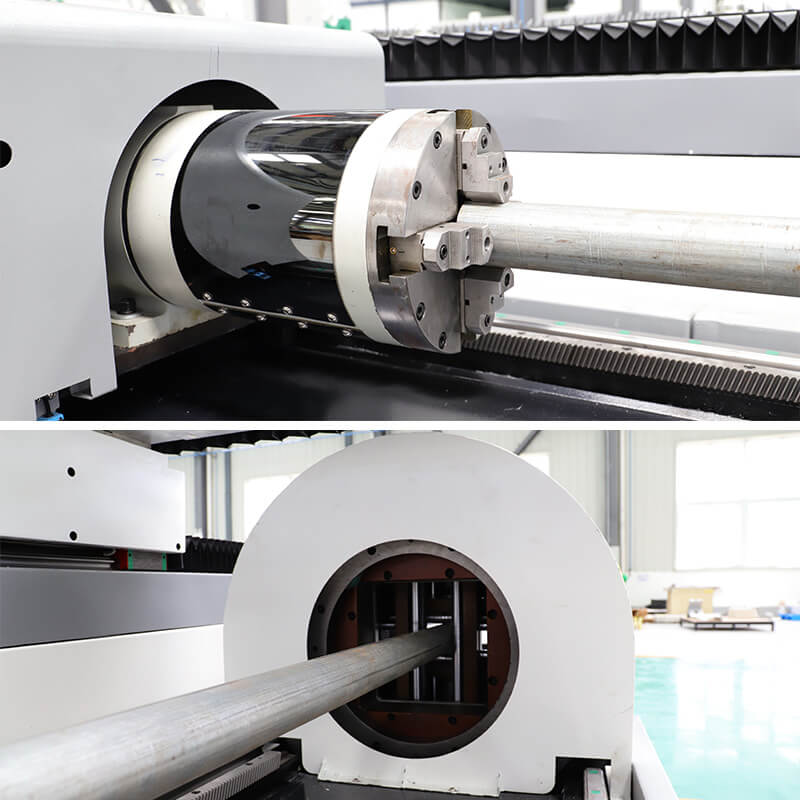

Equipped with four chucks, the cutting cost is saved without wasting materials.

Pneumatic Chuck

Cutting machine clamping becomes convenient, easy and fast, with 3 seconds at the soonest to clamp and high repeat precision.

Specialized Laser Head

The slender nozzle allows the laser tuber cutter to avoid interference and cut various types of tubes, including special-shaped tubes like H-Beam, P-Beam, I-beam, etc.

Tube Laser Cutting Machine Technical Parameters

| Model | iGR-T 6010 | iGR-T 6024 | iGR-T 6024B |

| Round Tube Diameter | 20-100mm | 10-240mm | |

| Square Tube Diameter | 10-100mm | 10-240mm | |

| Tube Length | 6m | ||

| Power | 1000w/ 1500w/ 2000w/ 3000w | ||

| Max. Moving Speed | 80m/min | 120m/min | 98m/min |

| Position Accuracy | ±0.03mm | ||

| Reposition Accuracy | ±0.02mm | ||

| Max. Acceleration | 0.8G | ||

| Max. Load | 180kg | 400kg | 300kg |

| Power Consumption | 12.5kw/ 15.0kw/ 18.0kw/ 22.0kw | ||

| Machine Dimension | 8640*1750*2150mm | 10700*2630*2500mm | 10700*2630*2500mm |

| Machine Weight | 2500kg | 5300kg | 5300Kg |

- Cutting Thickness: Fiber laser cutting machines are capable of cutting various thicknesses of metal tubes. The cutting capacity depends on factors such as the laser power, the material being cut, and the specific machine model. In general, fiber laser tube cutting machines can cut thin to thick-walled tubes, ranging from a few millimeters to several centimeters in thickness.

- 3D Cutting Capability: Some advanced fiber laser tube cutting machines offer 3D cutting capabilities. This means that the machine can cut tubes and pipes with complex shapes and angles, enabling the creation of intricate designs and patterns. 3D cutting is particularly useful in applications where precise and angled cuts are required, such as in the automotive, aerospace, and architectural industries.

- Software and Programming: Fiber laser tube cutting machines are usually equipped with user-friendly software interfaces that allow operators to program and control the cutting process. The software enables the design and import of cutting patterns, adjustment of cutting parameters, and simulation of the cutting path. Advanced software packages often include nesting optimization features to maximize material utilization and minimize waste.

- Additional Functions: Depending on the specific machine model, fiber laser tube cutting machines may offer additional functions and features. Some machines are equipped with rotary axis attachments, which allow for the cutting of curved and cylindrical surfaces. Others may have automatic focus adjustment systems to ensure optimal cutting performance across different tube diameters.

IGOLDENLASER,Make Metal Cutting Easier

Multi-industry applications: sheet metal industry, machinery industry, automobile industry, aerospace, cabinet industry, hardware industry, home appliance industry, door and window industry, construction industry, electromechanical industry, furniture industry.

Multi-material application: stainless steel, carbon steel, galvanized sheet, electrolytic sheet, aluminum, titanium, alloy, brass, copper, iron and other rare metal sheets.

Metal Tube Laser Cutting Machine

Laser cutting ensures high precision and accuracy in metal tube cutting. The focused laser beam allows for precise and clean cuts with minimal distortion. The machines can achieve tight tolerances and produce complex shapes, angles, and patterns on the tubes. Metal tube laser cutting machines can handle various tube shapes, including round, square, rectangular, and oval profiles. They can cut straight or angled edges, chamfers, holes, slots, and other geometries as per the design requirements.

Many metal tube laser cutting machines are equipped with automation features to enhance productivity and efficiency. They can be integrated into automated production lines or paired with robotic systems for seamless material handling, loading, and unloading. This reduces manual intervention and allows for continuous and uninterrupted cutting operations.

Metal tube laser cutting machines come with user-friendly software interfaces that allow operators to program and control the cutting process. The software enables the import of CAD files, design modifications, nesting optimization, and simulation of the cutting path. This facilitates efficient material utilization and reduces waste.

Features of Fiber Laser Tube Cutting Machine

- Fiber laser technology offers several advantages over other cutting methods. It provides a concentrated, high-energy laser beam that can easily cut through a wide range of materials, including steel, stainless steel, aluminum, brass, and copper.

- Fiber laser tube cutting machines provide exceptional cutting precision and accuracy. The focused laser beam enables the machine to achieve tight tolerances and produce clean, smooth cuts with minimal distortion.

- These machines are capable of cutting tubes and pipes of different shapes and sizes, including round, square, rectangular, and oval profiles. They can handle a variety of applications, such as cutting holes, slots, notches, and complex patterns on the tubes.

- Fiber laser cutting machines are known for their high cutting speeds, which significantly increase productivity in comparison to traditional cutting methods. They can rapidly cut through tubes and pipes, reducing production time and increasing overall efficiency.

- Many modern fiber laser tube cutting machines come with advanced automation features. They can be integrated into automated production lines, allowing for continuous and uninterrupted cutting operations. Automatic loading and unloading systems further enhance productivity and reduce manual labor.

- Fiber laser technology has fewer moving parts compared to other cutting methods, resulting in reduced maintenance requirements. Additionally, fiber lasers have a long operational life, providing a reliable and cost-effective cutting solution.

- Fiber lasers are highly energy-efficient, consuming less power compared to traditional CO2 lasers. This not only reduces operational costs but also contributes to environmental sustainability.

Fiber Laser Tube Cutting Machine stands out as a versatile, precise, and efficient solution for tube and pipe cutting requirements in industrial manufacturing. Its advanced features and capabilities make it an indispensable tool for enhancing productivity and competitiveness in modern manufacturing environments.

Tube Laser Cutting Machine Price

The price of a tube cutting laser machine can vary significantly depending on several factors, including the machine’s specifications, capabilities, brand, and the region where it is purchased. Additionally, prices can change over time due to market conditions and technological advancements. It’s always recommended to consult with equipment suppliers or manufacturers for accurate and up-to-date pricing information.

Generally, metal tube laser cutting machine is considered a significant investment due to their advanced technology and precision capabilities. They are typically more expensive than traditional cutting machines. The price range for a tube laser cutting machine can start from tens of thousands of dollars for smaller entry-level models and can go up to several hundred thousand dollars for larger, high-powered, and fully automated systems. It’s important to consider the specific requirements of your application and production needs when evaluating the cost of a tube laser cutting machine.

Factors such as the maximum tube diameter and length, laser power, automation features, software capabilities, and after-sales support should be taken into account to determine the appropriate machine for your business. Additionally, it’s advisable to consider the long-term return on investment (ROI) and the potential productivity gains and cost savings that the machine can offer.

Pingback: Tube Laser Cutting Machine for Stainless Steel - iGOLDENLASER