No products in the cart.

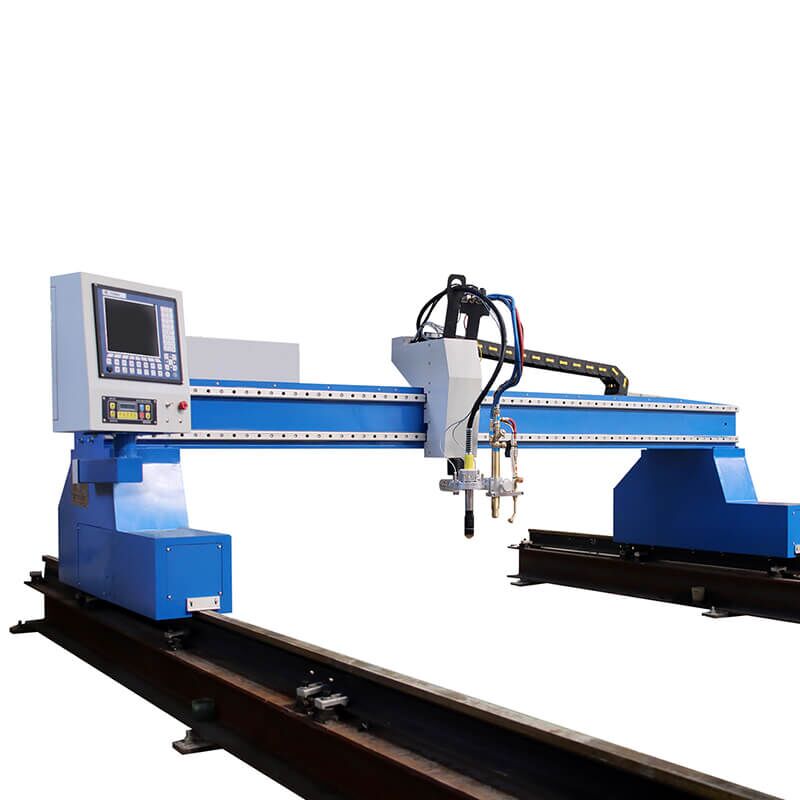

iGP-G

Gantry CNC Plasma Flame Cutting Machine

The whole machine is made of national standard 6mm steel plate by tailor-welding, and the structure of the whole machine is reasonably designed in accordance with the golden ratio. Grounding and anti-electromagnetic interference performance, different numbers of plasma flame cutting heads can be configured according to different requirements of customers to meet the requirements of different customers.

Gantry Pipe and Plateintersection cutting machine can achieve two kinds of tube and plate cutting method, can greatly save customers cost. The machine can cut a plurality of cylinder with different direction, different diameter of intersecting line hole, meet the vertical axis and axis condition branch director and no eccentric. The machine can also cut cylinder intersection line at the end of branch pipe, meet the pipe axis and the eccentric and no eccentric director axis intersecting condition.

Gantry cnc plasma cutting machine is specially designed for sheet metal fabrication, it is characterized of high automation and efficiency, easy operation and long service time.

Reviews

There are no reviews yet.