Buyer Guide

Glass Cup & Glassware Laser Engraving Machine

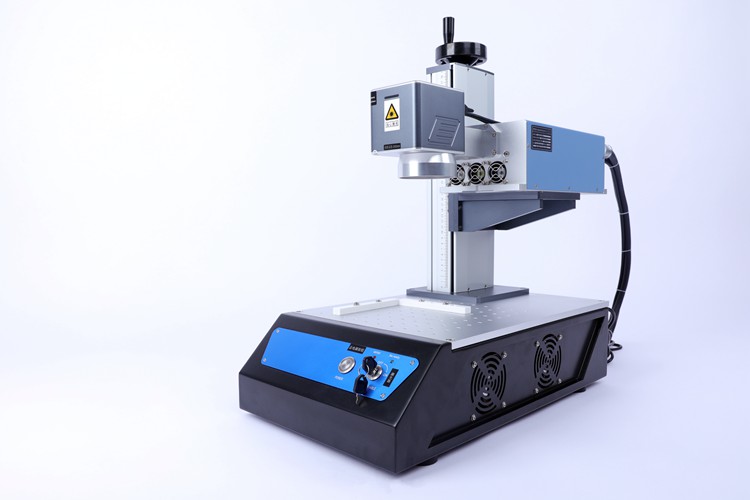

Glass Laser Engraving | Glass Laser Etching Machine For Sale

A glass engraving machine allows creating amazing masterpieces from the usual materials. The machine made by modern technologies. It has a lot of sensors that are responsible for the accuracy of movements during laser engraving. Errors are not possible due to the several levels of protection. The operator only needs to set the correct processing parameters of the machine.

A glass laser engraving machine is a specialized tool used to engrave designs, patterns, or text onto glass surfaces using laser technology. These machines utilize the precision and heat generated by lasers to create precise and detailed engravings on glass materials.

What Are the Benefits of the Glass laser engraving machine?

laser engraving makes more elegant lines; the speed of laser engravings much higher; the material is processed directly; thanks to the presence of a turning device, it is possible to engrave on cylindrical objects (vases, bottles); text and images can be of any complexity. The only limitation is the product surface area.

Glass laser engraving machines offer high precision and the ability to produce intricate and detailed designs on glass surfaces. The laser beam can be controlled to create fine lines, curves, and intricate patterns with high accuracy.

The depth of the engraving on glass can vary depending on the laser power and settings. Surface engraving creates a shallow etching on the surface of the glass, while subsurface engraving creates a 3D effect by engraving within the glass material. The depth achieved in subsurface engraving depends on the laser’s power and the number of passes made over the same area.

Glass laser engraving machines are compatible with various types of glass, including flat glass, curved glass, glass bottles, glassware, and more. However, the specific compatibility may depend on the machine’s design and capabilities. It’s important to check the machine’s specifications and ensure it is suitable for the type and thickness of glass you intend to engrave.

Get in touch with us right away, whether you’re looking for marking your complete production line or seeking customized marking solutions for your unique glass product or industry.

The procedure of glass laser engraving occurs in several stages:

The operator of the machine enters the parameters of the motion of the laser marker into the program.

Put your glass part to our machine work table.

With the help of the laser marking systems glass, elements of the established size are burnt out, which form the necessary pattern.

laser cup engraver

How Does Our Glass Marking & Engraving Solution Work?

The glass is a transparent, solid and homogenous material that is breakable, and marking on it presents a challenge. IGOLDEN’s Sealed CO2 and UV Laser Marking System performs glass etching for traceability and identification. It produces extraordinary marks that take care of the decorative aspect of the material being marked.

In sharp contrast to the traditional etching methods and solid-state laser solutions that are not only expensive but can potentially damage the material, our UV and CO2 Laser Marking Machine is permanent, reliable highly flexible, and easier on the wallet.

This reliable CO2 Laser Marking Technology comes in 20 watts and 30-watt versions. They are designed to meet a host of glass and water bottle etching needs. It is perfect for etching entire production lines with dates, logos, batch numbers product descriptions and more for a wide range of industries from food to chemical manufacturers.

Laser engraving machines emit powerful laser beams, so it is crucial to follow safety guidelines and take appropriate precautions. Ensure that the machine has safety features, such as interlocks, safety enclosures, and laser safety goggles, to protect operators from laser radiation.

Where the Glass Engraving Machine Can Be Used?

The problem of drawing inscriptions appeared with the invention of glass. Since ancient times, engravers have been valued for the ability to make glass markings antiques or glass markings on vases according to customers’ requirements.

In general, a laser etching is a common type of processing of various materials. It can be used on metal, wood, plastic, stone. But a only transparent material makes it possible to leave a mark not only on the external surface but also in the structure itself.

Currently, laser etching with a special machine on the surface of the glass has become in demand. This machine is used both for manufacturing and branding various industrial products. It is also in demand for decorating various souvenirs, for creating unique works of art such as engravings, imperial glass markings etc.

Car glass markings with the help of a laser are the original way to personalize your vehicle. The machine can create amazing pictures with laser marking. They will immediately attract the attention of all road users.

Thus, laser safety glass markings will suite:

- Representatives of a business as a corporate gift;

- Shops, in the assortment of which there are souvenirs and non-standard gifts;

- The agencies organizing solemn events;

- Everyone who like to surround themselves with beautiful things and present non-standard gifts.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.