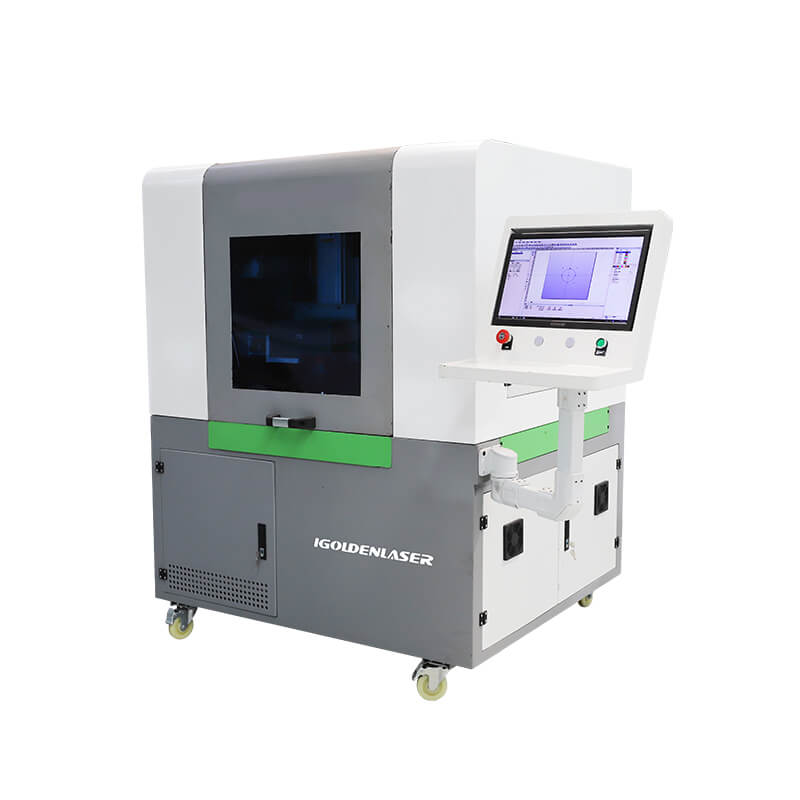

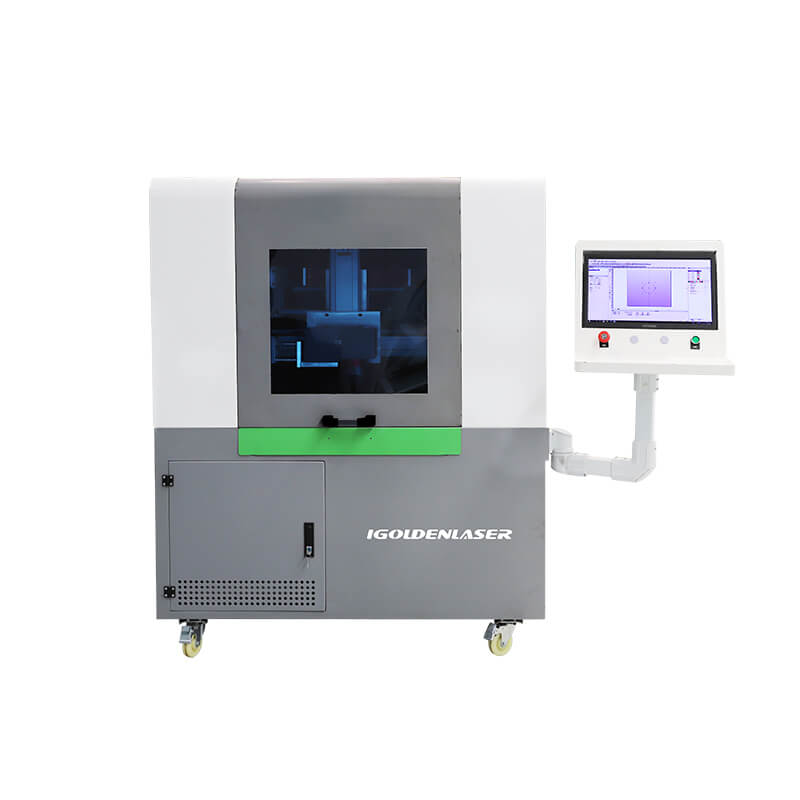

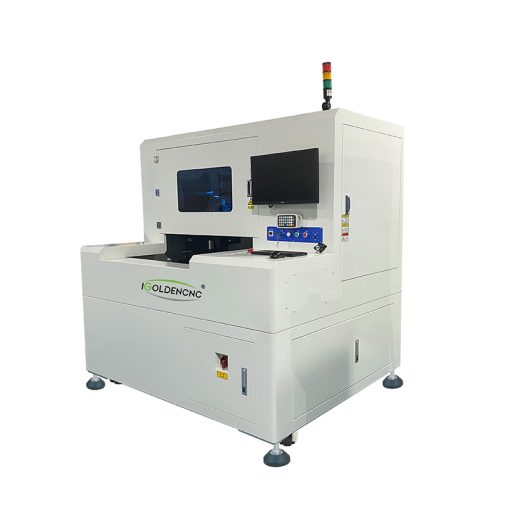

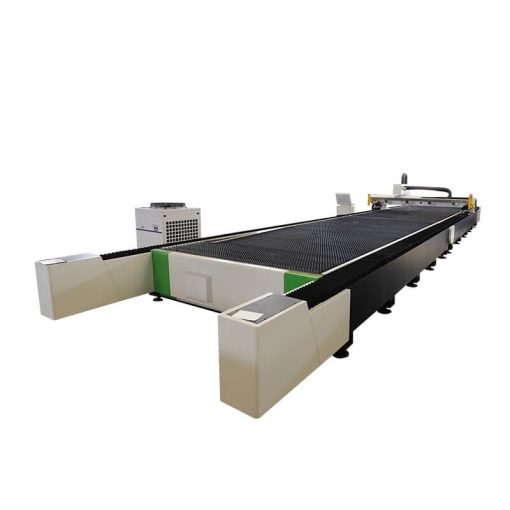

iGR-GC

Laser Automatic Glass Cutting Machine

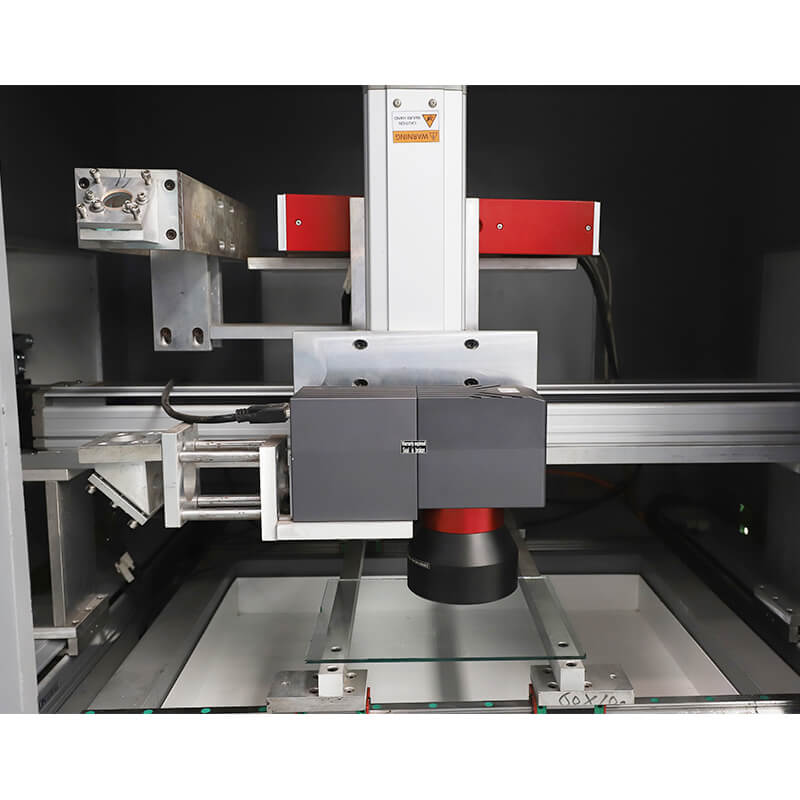

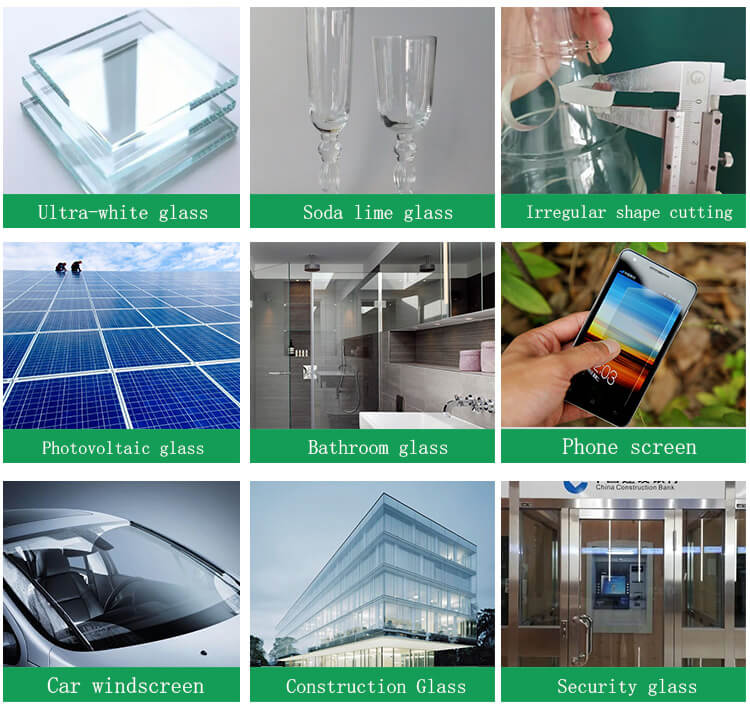

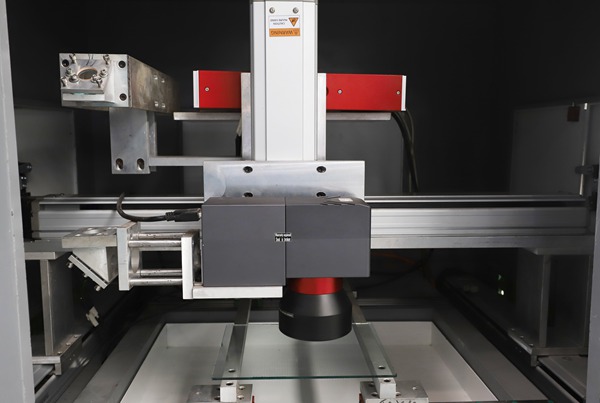

Designed with patented technology, our CNC glass laser cutter is capable of cutting glasses flawlessly. Our cutting machine does not cause much stress on the glass materials. Also, there is no risk of cracks and chips. You will find zero yield loss with the laser-based glass cutter.

High-definition image alignment and professional customized operation software control system make the production efficiency higher, the repeated positioning more accurate, and the operation easier. The equipment has been widely used in instrumentation glass/photovoltaic glass/mobile phone glass/medical instrument/vehicle display/panel display glass and other industries.

Mason –

We’ve been able to expand our product offerings thanks to the versatility of this machine. It cuts through different types of glass with ease and consistency.

Ethan –

The automated features and precision of this laser glass cutting machine have minimized material wastage, optimizing our production process.

Ava –

The laser cutter’s accuracy is unparalleled. We can achieve smooth edges and complex shapes effortlessly, which was challenging with traditional methods.