No products in the cart.

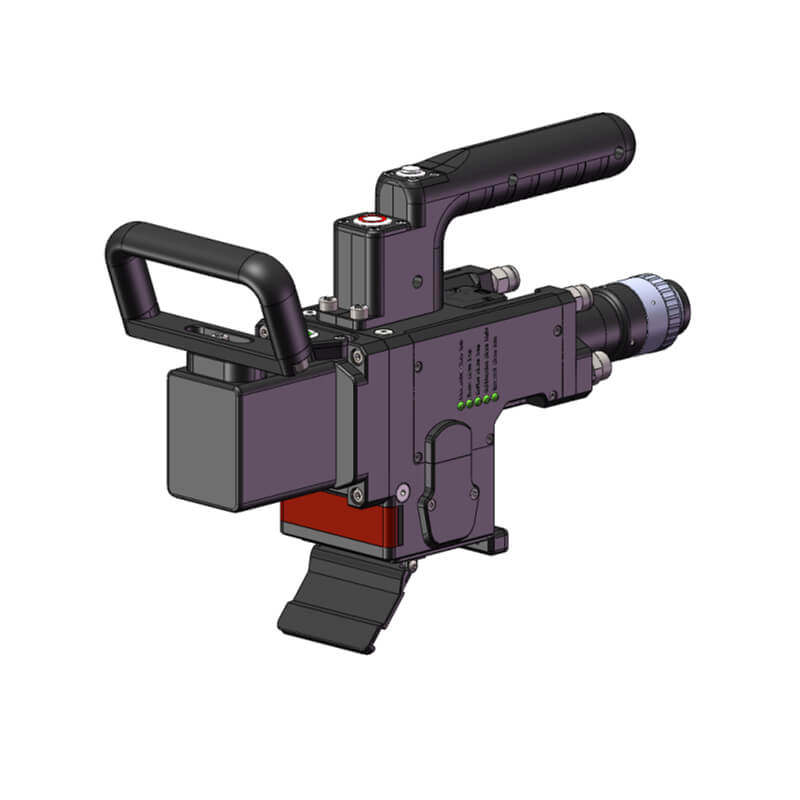

IGCL -6000w

Laser Rust Removal Machine

We’re excited to announce the upcoming launch of what could be the first 6000W laser cleaning machine on the market. This powerhouse is designed for maximum efficiency and precision, revolutionizing how industries like metalworking and fabrication handle surface cleaning, rust removal, and maintenance. Whether you’re cleaning rust from large metal surfaces or maintaining industrial equipment, this machine brings unmatched performance to your workspace.

The laser cleaning machine is suitable to clean not only organic pollutants, but also inorganic substances, including metal rust, metal particles, dust, etc. It can achieve the processing effects of rust removal, paint removal, oil removal, cultural relic repair, glue removal, coating removal, and plating removal. Moreover, It is suitable for cleaning processes, such as rust, thin paint layer, shallow oil stain or technical, derusting of metal polished surface, pre-heating process treatment of sheet metal parts, and other processes.

Reviews

There are no reviews yet.