Buyer Guide

Affordable Handheld Metal Laser Welding Machine for Sale

A metal laser welding machine, also known as a laser welder or laser welding system, is a specialized equipment used for precise and efficient welding of metal components. It utilizes laser technology to generate a highly concentrated and intense laser beam that melts and fuses metal materials together.

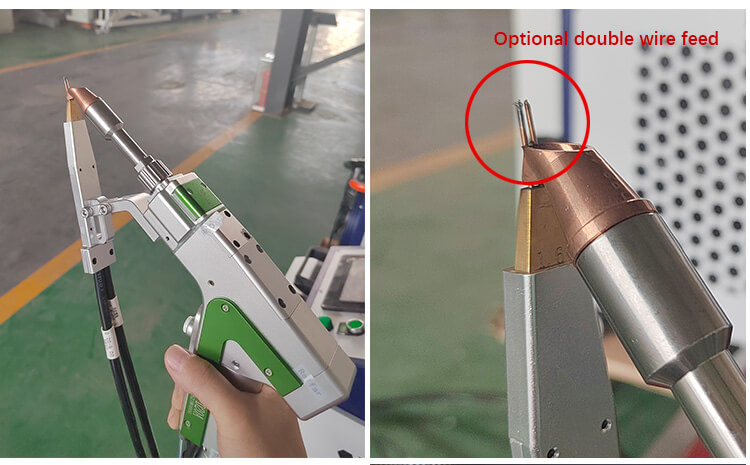

Handheld Metal Laser Welding Machine

Handheld metal laser welding machines are designed to be lightweight and portable, allowing for easy transportation and maneuverability. They typically have a compact size and ergonomic design, enabling operators to access and weld difficult-to-reach areas or perform welding tasks in different locations.

Handheld metal laser welding machines offer the advantages of mobility, accessibility, and versatility in metal welding applications. They provide a convenient solution for on-site repairs, small-scale production, or situations where traditional fixed-position laser welding machines may not be feasible.

Welding head

The laser is eventually fired from the welding head and applied to the material.It consists of nozzle,scale tube, protective glass,focusing lens, reflector,motor,collimator,wire feeding bracket, switch button, waterways,QBH protective sleeve and so on. Nozzle and protective lens are wearing parts. And when workers’ welding, auxiliary gas is often needed to avoid material producing gas that could react with air and to avoid residue and aerosol entering the welding head to damage the components.So we need to prepare extra nozzles and protective lens. How laser welding works?The laser is generated by laser source and is transported to welding head, then it is collected and reflected by reflector and is focused by focusing lens to reach the nozzle and finally fired to the material, after all this happens, the user could conduct welding conveniently and flexibly.

When considering a handheld metal laser welding machine, factors to consider include laser power, portability features, battery life (if applicable), cooling system, ease of use, and the specific welding requirements of your application.

Main body

Displayer is a window for interaction between user and machine. The screen of displayer is touch screen, its functions are machine parameter adjustment and language conversion. Control board equals to computer mainframe. And wire feeder is designed to melt the wire into the welding joint during material processing when the welding joint width over 5 mm.

Water chiller is used to cool laser source and welding head and could only be filled with distilled water and purified water in summer and with antifreeze in winter. And the volume of liquids contained is 15L, the replacement period of liquids is 2-3 months.

Metal Laser Welding Machine for Sale

Ranging from entry-level handheld laser welding guns to automatic laser welding systems with CNC controller, as well as professional 3D laser welding robot. All types of laser beam welders available in IGOLDEN with powers of 1000W, 2000W and 3000W for machinists.

Three-in-one laser welder

The advanced version of laser welder is the three-in-one laser welder, as its name suggests, it has multifunctions of of welding, cleaning and cutting. Its welding function is the same as that of a normal laser welder. And it could be easily to changed into the cutting pattern by the change of nozzle, when it is converted into the pattern of cutting, it could only cut some extra and useless pieces of the material edges with less precision and worse effect than normal fiber laser cutters. If it is applied in cleaning, cleaning head and special focusing lens for laser cleaner should be installed. It is easy and convenient in operation and alteration of patterns.

Metal Laser Welding Machine Features

Laser Source:

Metal laser welding machines use a laser source, typically a solid-state laser, to generate the laser beam. Common types of lasers used include fiber lasers, Nd:YAG lasers, and disk lasers. These lasers provide high power and excellent beam quality for precise and controlled welding.

Welding Process:

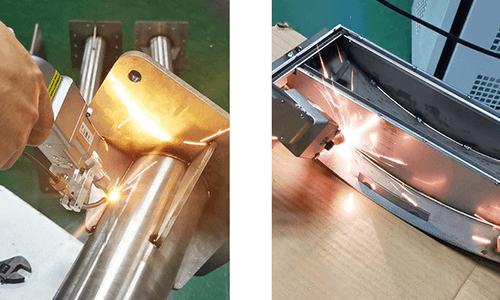

Metal laser welding involves focusing the laser beam onto the joint or area to be welded. The laser beam rapidly heats and melts the metal surfaces, creating a localized molten pool. Upon cooling, the molten metal solidifies, resulting in a strong and durable weld joint. The process can be performed in continuous wave (CW) mode or pulsed mode, depending on the application requirements.

Non-contact Welding:

Laser welding is a non-contact welding process, meaning the laser beam does not physically touch the workpiece. This eliminates the need for mechanical force or contact between the welding tool and the material, reducing the risk of contamination or damage to the welded parts.

Materials:

Metal laser welding machines can be used to weld a wide range of metals and alloys, including stainless steel, carbon steel, aluminum, titanium, copper, brass, and various other alloys. They are particularly effective for welding thin sheets or components with high precision and minimal distortion.

Speed and Efficiency:

Laser welding is a fast and efficient welding method. The concentrated energy of the laser beam results in rapid heating and cooling rates, allowing for high welding speeds. This contributes to increased productivity and reduced production time compared to traditional welding techniques.

Precision and Control:

Metal laser welding machines offer high precision and control over the welding process. The laser beam can be accurately focused and directed to the desired welding area, allowing for precise positioning and control of the heat input. This enables the welding of intricate or complex geometries with minimal damage to the surrounding material.

Versatility:

Metal laser welding machines are versatile and can be used for various welding applications. They can perform spot welding, seam welding, overlap welding, and even 3D welding of complex components. Laser welding can also be combined with other processes, such as laser cutting or laser marking, to create integrated manufacturing solutions.

Automation and Integration:

Metal laser welding machines can be integrated into automated production lines or robotic systems for increased productivity and consistency. They can be equipped with vision systems and sensors to aid in precise positioning and quality control.

Metal Laser Welding Machine Advantages

The laser welder has varieties of advantages and they will be explained in detail. Laser welder could be used in a wide range , it works well no matter in outdoor or from long distance. And the machine can be used flexibly and conveniently in various working occasions. Besides, there are many welding methods offered for users to choose, stitch welding, butt welding, vertical welding, flat fillet weld, inside corner weld and outside corner weld, and it has free switching of welding and cutting, users only need to change a welding nozzle to a cutting nozzle. The welding effect is good because of small heat affected zone, hard to deform and blacken, welding deeply, full melting, compact and firm structure, high weld strength.

There is no need to polish welding joint for it adopts continuous welding, the surface of welded part is smooth and well-done with no perlage and few subsequent polishing procedure. Little consumable material needed in welding process to save the costs of material. This machine is equipped with safety alarms. The nozzle works only when it touches metals and automatically stops outputting laser once the working parts moved from the platform, and the tact switch has the function of temperature sensing. Therefore, this machine has a high safety level. Last but not the least, laser welder is labor-saving for it could be operated by workers who only have short-term training. In a nutshell, the laser-welder is friendly to both owner and user with advantages of time saving, labor saving and cost saving.

How does laser welding work?

Welding by laser beam is basically very simple: Two precisely cut sheets are held together. The laser melts the edges of the sheet metal. The melt flows into each other – and the joint is complete.

Quality assurance in laser beam welding

Laser beam welding is a non-contact joining process. It is always carried out automatically. Modern laser beam welding systems are equipped with an integrated measuring system, which independently checks the dimensions of the manufactured component. This makes these systems particularly precise, which is the basis for guaranteeing constant quality.

Costs for a laser beam welding system

The costs are still the biggest disadvantage of these innovative processes. It depends strongly on what and which material is to be processed with the laser welding system. Even simple micro systems used, for example, for engraving wedding rings can cost several thousand euros. Brand-new high-performance plants rarely cost less than 100,000 euros, rather more. These expenses are offset by excellent manufacturing quality and high productivity. In fact, laser welding is usually carried out at a much higher speed than conventional electric or inert gas welding processes.

What speed is possible with laser welding?

In addition to precision and low heat input, the working speed is one of the outstanding properties of laser welding. Under ideal conditions, a long, straight endless seam can be welded at a speed of up to 60 m/minute. Since the intensity of the laser beam can be varied, the impact of the material used is less decisive for the working speed of a laser welding system. Even thick sheets can be precisely joined in a matter of seconds.

Types of laser welding

Laser welding is a versatile, low cost way of achieving high quality spot welds for different materials and thicknesses. It results across a wide range of materials. There are three common types, including CO2, YAG and fiber laser welders. There are high-power welders for large-format and thick sheets, and low-power welders for small-size parts. There are welders for metals and non-metallic materials such as plastics and ceramics.

Different methods can be classified as follows:

• Welds between slices. Including butt welds, end welds, center penetration fusion welds, and center perforation fusion welds.

• Wire and wire welds. Including wire-to-wire butt welds, cross welds, parallel lap welds, and T-type welds.

• Welds of metal wires and block components. It can successfully realize the connection between the metal wire and the block element, and the size of the block element can be arbitrary. Attention should be paid to the geometric dimensions of the wire-like components during welding.

• Welds of different metals. Welds different types of metals must solve the range of weldability parameters. The welding between different materials is only possible with certain material combinations.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.