Laser Knowledge

How Much Does a Laser Welder Cost

Laser technology has revolutionized the field of welding, providing precise and efficient solutions to various industries. The emergence of laser welding machines has replaced traditional welding technology, providing better control, speed and quality. Among them, handheld metal laser welding machines are popular for their versatility and ease of use. If you are considering investing in a laser welding machine, it is crucial to understand the cost factors involved. In this article, we will explore the various aspects that determine the price of a laser welder.

How Much Does a Laser Welder Cost

When it comes to pricing, the market offers a variety of options. A basic handheld metal laser welder costs around $5,000, while more advanced models with additional features and higher power output can cost up to $25,000. Variations in cost are attributed to several factors, including laser power, wavelength, cooling systems and the machine’s automation capabilities. Laser power is a key determinant of laser welding machine price. Higher power output enables faster and deeper welds, increasing efficiency. However, this also increases the cost of the machine. For most handheld metal laser welding machines, the power output range is 1000W to 3000W, and the price increases accordingly. Therefore, it is crucial to evaluate your welding needs and select a machine with the appropriate power output.

Laser Welder Price

| Laser welder | Power | Price |

| Fiber Laser Welding Machine | 1000w | $5,000 |

| Laser Welding Gun | 1500w | $6,000 |

| Handheld Laser Welding Machine | 2kw | $9,500 |

| Handheld Laser Welder | 3kw | $12,000 |

| Multi-Function 3 in 1 | 1000w | $6,000 |

| Multi-Function 4 in 1 | 2000w | $9,000 |

| Multi-Function 5 in 1 | 3000w | $13,000 |

| Robot Laser Welding Machine | 1000w | $20,000 |

This Multi-Function 3 in 1 laser welder is low cost. It is a machine specially researched for small businesses. The low price can ensure that all small businesses can afford it. It can easily weld smooth seams and supports various functions such as spot, full, and continuous welding. If you want to buy a laser welder for your business production, choose this 3 in 1 is fully able to meet your various needs.

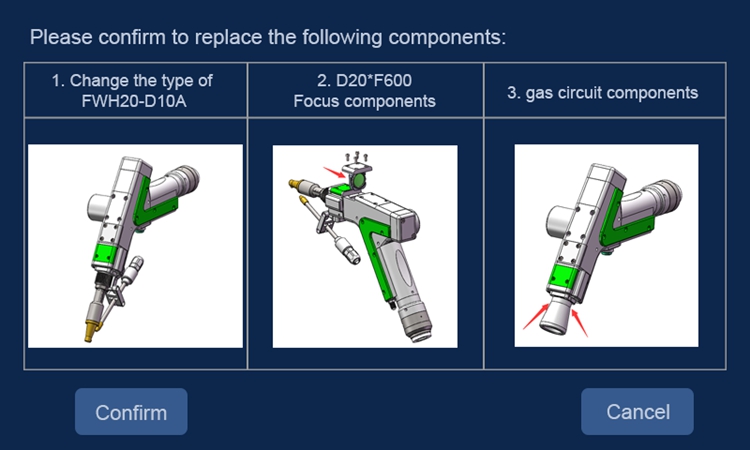

Multifunction laser welding, cleaning, cutting machine is composed of fiber laser generator, handheld laser gun, water chiller, and 5 in 1 control system, which is used for laser welding, cleaning and handheld cutting. Each handheld laser gun is portable, convenient, and easy to use.When you need to handle different processes, you can quickly change nozzles, lenses, and control systems. 5-in-1 Handheld Laser Welding Cleaning and Cutting Machine can not only cut and weld metal but also clean rust, paint, resin, coating, oil, and stains.To provide a more efficient and flexible solution for the market, the system comes with a process parameter library for common materials and thicknesses.For different application scenarios, it can easily and quickly replace the corresponding nozzle of the gun head, plug and play, so that the cumbersome processing becomes simple and the processing efficiency is higher.

The cost of a handheld laser welder machine can vary significantly depending on factors such as the manufacturer, specifications, features, and the intended application. Handheld laser welders are available at different price points, ranging from a few thousand dollars to tens of thousands of dollars. For specific and up-to-date pricing information, it is recommended to contact manufacturers or suppliers directly, as prices can change based on market conditions and technological advancements.

Factors Influencing Laser Welding Costs

Laser welder cost is also closely related to after-sales service, welding effect, and brand. It is very expensive if you want a machine with high speed, high power, and good welding results. In choosing a laser welder, you should pick the most important parameters based on your budget.

Laser power is a key determinant of laser welding machine price. Higher power output enables faster and deeper welds, increasing efficiency. However, this also increases the cost of the machine. For most handheld metal laser welding machines, the power output range is 1000W to 3000W, and the price increases accordingly. Therefore, it is crucial to evaluate your welding needs and select a machine with the appropriate power output.

Another factor that affects cost is the cooling system. Laser welding machines generate heat during operation, and an efficient cooling system is critical to preventing overheating and maintaining performance. More advanced cooling systems, such as water or air cooling, will increase the overall cost of the machine.

Wavelength selection also affects the cost of the laser welder. Different wavelengths are suitable for welding specific materials, such as carbon steel, stainless steel or aluminum. Machines with multiple wavelength options tend to be more expensive due to the additional components required for flexibility.

Automation capabilities are also a consideration when considering the cost of a laser welder. Some machines offer automation features such as robotic integration, automatic positioning and programming options, making them suitable for high-volume production. However, these advanced features come with a hefty price tag.

Laser Welder Advantages

1. After focusing laser, the power density is high. After the high-power low-order mode laser is focused, the focal spot diameter is very small.

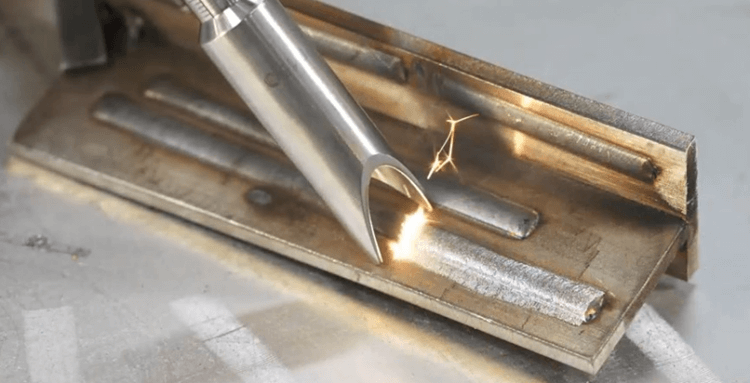

2. The laser welding speed is fast, the depth is large, and the deformation is small. Due to the high power density, small holes are formed in the metal material during the laser welding process, and the laser energy is transmitted to the deep part of the workpiece through the small holes, and there is less lateral diffusion. The speed is fast, and the welding area per unit time is large.

3. The welding depth-to-width ratio is large, the specific energy is small, the heat-affected zone is small, and the welding deformation is small. It is especially suitable for the welding of precision and heat-sensitive parts, which can avoid post-weld orthopedic and secondary processing.

4. It can be welded at room temperature or under special conditions, and the welding equipment is simple.

5. It can weld refractory materials, such as titanium, quartz, etc., and can weld materials of different materials, such as copper and tantalum, two metals with completely different properties are welded together, and the effect is good.

6. Micro-welding can be carried out. After the laser beam is focused, a small spot can be obtained, and it can be precisely positioned, which can be applied to the assembly welding of micro and small components in mass automatic production. Not only the production efficiency is greatly improved, but also the heat-affected zone is small and the solder joint is free of pollution, which greatly improves the quality of welding

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.