Laser Knowledge

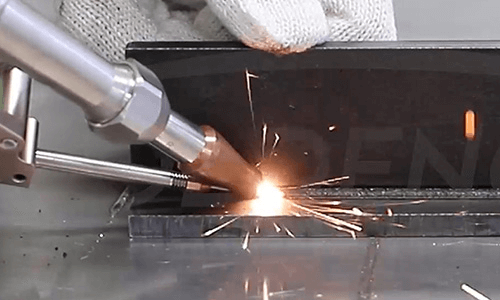

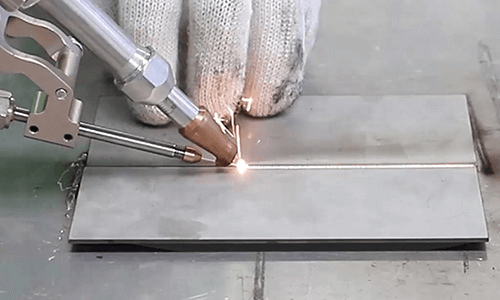

How thick can a handheld laser welder weld?

The thickness that a handheld laser welder can weld depends on several factors, including the power output of the laser, the type of material being welded, and the specific welding parameters used. Generally, handheld laser welders are suitable for welding thin to moderately thick materials.

However, it’s important to note that handheld laser welder may have limitations compared to larger, more powerful laser welding machines. In terms of stainless steel, which is a commonly welded material, a handheld laser welder can typically weld stainless steel thicknesses ranging from a few tenths of a millimeter (0.01 inches) up to a few millimeters (0.1 inches). Thicker sections of stainless steel may require multiple passes or alternative welding methods.

It’s crucial to consult the manufacturer’s specifications and guidelines for the specific handheld laser welder you are considering, as the capabilities and limitations can vary among different models and brands. Additionally, testing and experimentation with sample materials are recommended to determine the optimal settings and achievable weld quality for the desired stainless steel thickness.

Handheld Laser Welder Weld

In recent years, the application of stainless steel sheet is more and more extensive, in mold repair, hardware and crafts spot welding, electronic components, stainless steel sanitary appliances, faucets, mobile phone shell studs, stainless steel elbow joints, clocks, precision mechanical products, etc. Therefore, the packaging and welding of ultra-thin stainless steel products become very important. Then how thick can the hand-held laser welding machine weld (metal laser welding machine)!

The traditional welding method is difficult to ensure the welding forming quality of sheet metal, and laser welding has the advantages that the traditional welding can not compare, which can effectively reduce the welding defects. In the laser welding industry, there are many manufacturers that use laser to weld stainless steel parts, the welding effect of laser welding machine is also very good, and laser welding is also a good choice for stainless steel materials. How thick is the hand-held laser welding machine?

The depth of laser welding is related to the properties of materials, including the thickness of materials. It is impossible to select the same parameters for welding carbon steel and titanium materials. The problem of how thick the laser welding machine can weld is mainly around the steel plates with different thickness of 0.5-3mm and the welding machines with different power of 1000W, 1500W and 2000W.

Laser melting depth data reference

| Material | 1000W | 1500W | 2000W |

| Stainless steel | 0.5-3mm | 0.5-4mm | 0.5-5mm |

| Aluminum | 0.5-2.5mm | 0.5-3mm | 0.5-4mm |

| Brass | 0.5-3mm | 0.5-6mm | 0.5-8mm |

| Carbon steel | 0.5-3mm | 0.5-4mm | 0.5-5mm |

| Galvanized sheet | 0.5-3mm | 0.5-4mm | 0.5-5mm |

Laser Welding Speed

| Collimation focal length:150mm Focus length:250mm Fiber diameter:50μm Protection gas>15L/min | |||

| Material | Output Power | Penetration(mm) | Speed(m/min) |

| Stainless steel | 1000 | 0.5 | 8.5 |

| Stainless steel | 1000 | 3 | 0.85 |

| Stainless steel | 1000 | 2.5 | 2.55 |

| Stainless steel | 1000 | 2 | 3.4 |

| Stainless steel | 1000 | 1.5 | 5.1 |

| Stainless steel | 1000 | 0.5 | 12.75 |

| Carbon steel (low) | 1000 | 2.5 | 0.85 |

| Carbon steel (low) | 1000 | 2 | 2.55 |

| Carbon steel (low) | 1000 | 1.5 | 4.25 |

| Carbon steel (low) | 1000 | 1 | 6.8 |

| Carbon steel (low) | 1000 | 0.5 | 11.05 |

| Aluminium | 1000 | 1 | 3.4 |

| Aluminium | 1000 | 2 | 0.85 |

| Copper | 1000 | 0.3 | 1.7 |

Application and applicable materials of handheld laser welding machine industry:

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.