Laser Knowledge

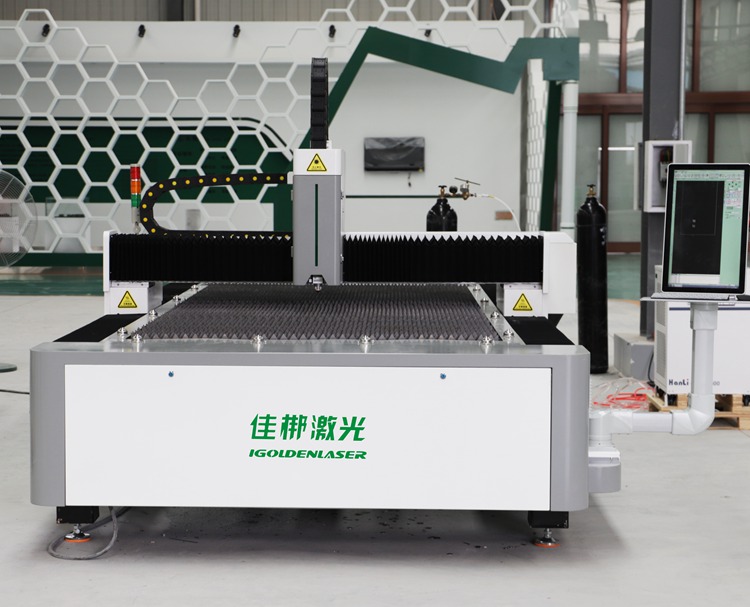

How to choose the suitable fiber laser cutting machine?

In recent years, laser cutting technology has been more and more widely applied in sheet , handicrafts and other processing industries. Fiber laser cutting machine technology has been quite mature, cutting industry features a very large market share. But there are still tons of users about the way to choose an appropriate fiber laser cutting machine, and there are all types of problems.

Here i will be able to introduce the way to choose a fiber laser cutting machine correctly, which may be considered from the subsequent aspects.

1. the wants for the materials and business processed by the enterprise

First of all, we should always consider the scope of our business, the thickness of the cutting material, which material must be cut, then determine the dimensions of the equipment that must be purchased and therefore the size of the worktable. at the present , the facility of the laser cutting machine on the market is between 500W-6000W, and therefore the size of the manufacturers of the worktable are often consistent with the customer. Demand to customize.

2. The initial choice of the manufacturer

After we confirm the demand, we will attend the market to know or to ascertain the performance and basic parameters of the machine. Select variety of strong and price preferential manufacturers for early communication and sample, and later we will perform field inspection, the worth of the machine, machine training, payment methods, after-sales service then on more detailed discussion.

3. the dimensions of laser power

When we choose the performance of laser cutting machine, we should always give full consideration to our surroundings . the dimensions of the laser power is extremely important, for instance , we frequently cut the metal sheet below 6mm, then we elect 100W-2000W laser cutting machine to satisfy the demand of production. If we cut quite 6mm material, we’d like to think about a bigger power machine, which is extremely helpful to the value control of enterprises.

4. The core a part of the laser cutting machine

We also got to pay great attention when choosing some important parts of laser cutting machines. especially , the laser generator, laser cutting head, servo motor, guide rail, cistern , etc., we’ve to differentiate whether it’s made in China or imported. of these components directly affect the cutting speed and accuracy of laser cutting machine.

5. Equipment quality and use stability also are important indicators.

Now the research and development cycle of the merchandise is brief , the renewal and replacement are becoming faster and faster. the variability of products, the sample trial production and therefore the production are more. the way to guarantee the customer order, maintain the reputation of the enterprise, and enhance the competitiveness of the enterprise is additionally the arduous task for every operator. Therefore, the choice and buy of stable processing equipment is that the premise and basis, as far as possible to settle on the brand with high market share, perfect after-sales service system, many after-sales service outlets and long market inspection. we will not covet cheap products and buy poor quality products without after-sales service, which can have an enormous impact on the assembly of enterprises.

6. After-sale service

The after-sales service of every manufacturer varies greatly, and therefore the warranty time is uneven. In after-sales service, we should always not only provide customers with effective daily maintenance programs, but even have knowledgeable training system to assist customers start as soon as possible.

No matter how good a laser cutting machine is doing, the user will encounter a spread of problems within the process of using it. When it meets the matter that the customer can’t solve, it’s vital for the manufacturer to supply a timely solution. it’s also a crucial consideration once we prefer to choose the laser cutting machine.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.