Laser Knowledge

How to Use Laser Cutting Machine

Whether you’re a beginner or an experienced user, operating a laser cutting machine requires proper setup, safety precautions, and knowledge of materials. Here’s a complete guide to using a laser cutter effectively.

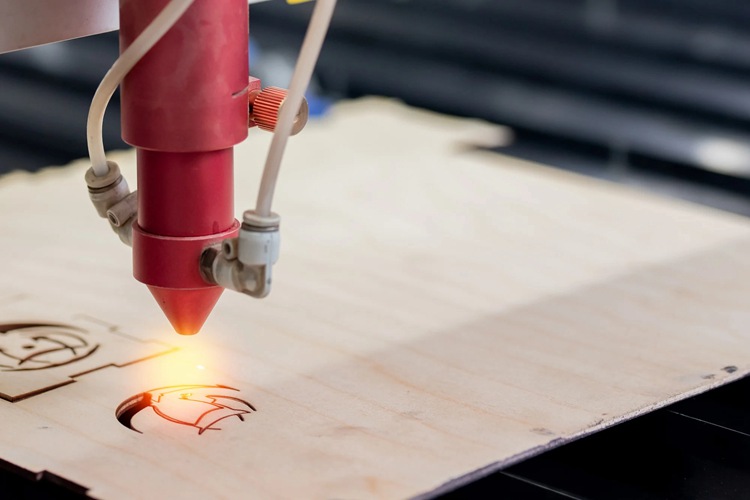

Using a laser cutting machine involves a series of careful steps to ensure safe operation and accurate cutting. Laser cutting is a highly precise method used to cut a variety of materials, including metals, plastics, wood, and fabrics.

How to Use Laser Cutting Machine

1. Understand the Types of Laser Cutting Machines

Before operating a laser cutting machine, familiarize yourself with its different types, including:

- CO2 Laser Cutters: Suitable for cutting non-metal materials like wood, acrylic, and some plastics.

- Fiber Laser Cutters: Ideal for cutting metals, including steel, aluminum, and brass.

- Nd:YAG Laser Cutters: Typically used for metal cutting in industrial applications.

2. Safety Precautions

Safety should always be the top priority when using laser cutting machines. Follow these safety guidelines:

- Wear Protective Gear: Always wear safety glasses, gloves, and appropriate clothing. Ensure that your clothing is not loose to avoid any accidents.

- Fire Safety Measures: Keep fire extinguishers nearby, as laser cutting can produce sparks that may ignite flammable materials.

- Ventilation: Ensure that the workspace is well-ventilated or use a fume extraction system to avoid inhaling harmful fumes produced during the cutting process.

- Familiarize Yourself with Emergency Controls: Know how to quickly shut down the machine in case of an emergency.

3. Prepare Your Material

- Select the Material: Choose the appropriate material you wish to cut (wood, acrylic, metal, etc.). Ensure that it is compatible with the laser cutting machine being used.

- Measure and Cut to Size: Measure your material accurately and, if necessary, cut it to the desired dimensions before placing it in the machine.

4. Design Your Project

- Create a Design: Use CAD (Computer-Aided Design) software to create the design you wish to cut. Most laser cutting machines accept common file formats such as DXF, AI, SVG, and PDF.

- Adjust Settings Based on Material: Configure appropriate settings, such as speed, power, and frequency, based on the material and thickness. This may require consulting the machine’s manual or manufacturer’s guidelines.

5. Set Up the Laser Cutting Machine

- Power On the Machine: Turn on the laser cutting machine and all necessary peripherals.

- Load the Design File: Import your design file into the laser cutting machine’s software and ensure that it is properly positioned within the workspace.

- Position the Material: Place the material onto the cutting bed, ensuring that it is flat and securely positioned. If required, use clamps or weights to hold the material in place.

6. Focus the Laser

- Focus the Lens: Adjust the laser’s focus according to the material thickness. Many machines come with autofocus features, but manual adjustments may be necessary for certain applications.

7. Perform a Test Cut

- Conduct a Test Cut: Before cutting the actual material, perform a test cut on a scrap piece of the same material. This step helps you verify the settings and make adjustments if needed.

- Evaluate the Test Cut: Check the test cut for accuracy and quality. If the cut is not satisfactory, adjust the machine settings as necessary.

8. Start the Cutting Process

- Begin Cutting: Once everything is set and tested, start the cutting process. Monitor the machine closely to ensure everything runs smoothly.

- Never Leave the Machine Unattended: Stay near the machine during operation to handle any potential issues that may arise.

9. Handling the Finished Piece

- Collect Your Cut Pieces: Once the cutting is complete, carefully remove the cut pieces from the machine using appropriate tools to avoid burns or injury. Be cautious of sharp edges.

- Inspect the Cuts: Check the quality of the cuts and ensure they meet your design specifications.

10. Clean Up After Cutting

- Turn off the Machine: Once you’re done, power off the laser cutting machine and any associated equipment.

- Clean the Workspace: Remove any debris, leftover material, and dust from the cutting area, and keep the machine and work area tidy.

- Perform Maintenance Checks: Regularly check the laser cutting machine for any maintenance needs and clean the optics and lenses according to the manufacturer’s guidelines.

Conclusion

Using a laser cutting machine effectively combines technical knowledge, safety awareness, and practical skills. By following the outlined steps, you can operate the machine safely and achieve high-quality cuts. Always refer to the specific manufacturer’s instructions for your laser cutter, as different machines may have unique features and requirements. With practice and patience, you’ll become proficient in using this powerful tool for various cutting applications.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.