Buyer Guide

Industrial Textile Fabric Leather Rubber Laser Cutting Machine

A textile fabric, leather, and rubber laser cutting machine is a specialized equipment used for precision cutting and engraving of various materials in the textile, leather, and rubber industries. It utilizes laser technology to deliver high-speed, accurate, and clean cuts or engravings. Here are some key features and benefits of laser cutting machines for these materials:

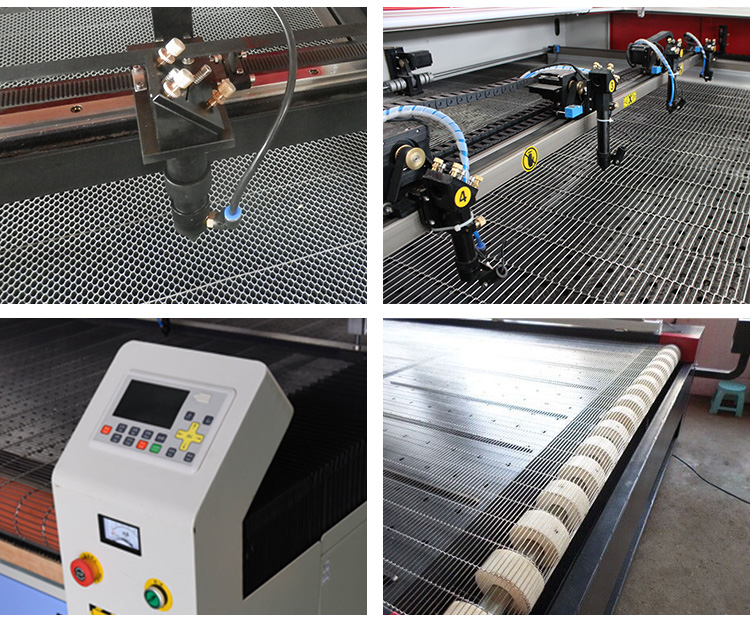

CO2 fabric laser cutter

The CO2 fabric laser cutter is designed for wide textile rolls and soft materials automatically and continuously cutting. Driven by gear and rack with servo motor control, the laser cutting machine offers high precision and cut quality at the highest cutting speed and acceleration. The laser cutter machine is available with a laser power from 150 watt to 800 watt. The large format cutting table can be applied to most of the typical fabric rolls.

Rubber Laser Cutting Machine

CO2 laser cutting has a better cutting effect on rubber sheets, and is especially suitable for making seals, seals, and rubber parts. Laser cutting produces smooth, fine cuts, making rubber products widely used in industrial and printing industries.

With the option of the auto-feeder, roll materials are fed to the cutting table directly and cut continuously. The machine is with vacuum suction underneath the conveyor working table, which ensures the materials to be flat on the table. Different vision systems can be equipped with this laser machine for diversified application such as dye sublimation printed textile cutting. And mark pen or ink-jet print head option is available to make marks for sewing or other purpose.

- This series CO2 flatbed laser cutting machine is designed for wide textile rolls and soft materials automatically and continuously cutting.

- Driven by gear and rack with servo motor, the laser cutter offers the highest cutting speed and acceleration.

- The software package and extra options come with the laser cutting system is provided to achieve digital and intelligent processing.

Industrial Fabric Laser Cutter Projects

Laser fabric cutting systems can cut any computer-designed shape. Due to the combination of laser and computer technology, the user can realize the laser cut output as long as the design on the computer, and the working can be changed at any time, and the product can be cut while designing.

Laser fabric cutting systems break the traditional manual and electric shears, which are slow and difficult to typesetting, and fully solves the problem of inefficiency and waste of materials. The cutting speed is fast and the operation is simple. You only need to input the graphics and dimensions to be cut into the computer, and the machine The whole piece of material will be cut into the finished product you need, without tools or molds, using lasers to achieve non-contact processing, which is simple and fast.

Features of Co2 Laser Cutting Machine

- This laser cutting machine delivers fast and extremely accurate processing thanks to its high-quality components. Very dependable and maintenance free.

- High precision grade gear and rack driving system. With high-powered CO2 laser tube, cutting speed up to 1,200mm/s, acceleration up to 8,000mm/s2, and can maintain long-term stability.

- This laser machine comes with conveyor system. The machine feeds the material automatically in a continuous cycle in synchronism with the conveyor bed eliminating downtime completely to achieve the maximum productivity possible. In addition, the vacuum conveyor worktable has the function of negative pressure adsorption to ensure the flatness of the fabric during laser cutting.

- Automatic feeder with deviation correction function (optional) to ensure accurate feeding.

- The unique manual and automatic interactive nesting software function can improve the fabric utilization to the extreme.

- Along with the exhaust system, the laser head and the exhaust system synchronize; good exhaust effect, to ensure that dust dose not pollute the materials.

- It is possible to complete entire format cutting of the extra-long layout with a single layout length that exceeds the cut format. • The laser cutting system is modular in design as per customers’ processing demands.

Clean edges – Lint-free cuts

The laser automatic seals the cutting edges and thus, prevents fraying. Compared to mechanical cutting, laser cutting saves many working steps in further processing.

Continuous cutting from roll

Laser cutting textiles and fabrics directly from the roll thanks to the conveyor system and automatic feeder. Capable of ultra-long format processing.

Laser cutting of extremely fine details

Laser is ideally suitable for cutting absolutely incredibly complicated internal shapes and designs, even cut extremely small holes (laser perforation).

Industrial Laser Fabric Cutting Machine Applications

Laser fabric cutter is suitable for cutting all kinds of nylon cloth, polyester cloth, canvas, waterproof cloth, microfiber dust-free cloth and other fabrics, especially suitable for cutting larger size products, such as sports goods, leisure travel goods, etc. It can also be used for processing veneer cut flowers, leather products, acrylic products, etc. The basic principle of the laser fabric cutting system is to use a laser beam with high intensity and concentrated direction as a cutting tool, and use the laser beam to melt the fiber material to realize the cutting operation.

The precision of the laser fabric cutting system is very high, and the cutting error generally does not exceed ±0.01mm, which can reduce the gap between adjacent garment pieces to approximately zero after discharging.

Applicable Industries

Fabric and clothes industry, shoe industry, home textile, embroidery, toy, leather, luggage, outdoors, sports, car seat, etc.

Applicable Materials

Genuine leather, artifical leather, soft leather, decorative leather, packaging leather, pure cotton, real silk, chemical fiber, denim, textile, non-woven materials.

Typical Cases

Clothing, footwear, toy, luggage, wild camp, car seat cut, car chair affixed cloth embroidery, special-shaped trademarks, airbags, garment leather patterns or designs hollow cutting.

Contactless laser processing.

No fabric distortion No tool wear.

Consistently high cutting quality.

High precision and accuracy repeatability.

Simple production via a PC design program.

High flexibility in cutting sizes and shapes.

without tool preparation or tool changes

Choosing the best industrial fabric cutting machine for your workshop will depend on your specific needs. You must take following factors into consideration to make the right choice, such as factory business model, cutting fabric types, daily production, purchasing budget, factory space, operator skill requirement, if need dies or nesting software, cut pattern quality, material wastage, consumables and electricity consumption of each machine, etc.

What Is Textile Fabric Leather Rubber Laser Cutting Machine?

Fabric laser cutting machine is a type of CO2 laser cutting system with automatic feeder and roller for all types of fabrics (silk fabrics, pure cotton fabrics, decorative fabrics, polyester fabrics, chemical fiber fabrics, pure linen fabrics), felts, grey fabrics, dust-free cloth, non-woven fabrics, patch embroidery, leather (leather, artificial leather, decorative leather) , Packaging leather, soft leather) and other clothing accessories and leather materials cutting or engraving.

Laser fabric cutting machine is mainly used in clothing industry, shoe industry, home textile industry, embroidery industry, trademark industry, cloth toy industry, leather industry, luggage industry, umbrella industry, medical industry, purification industry, aviation industry, and warp knitting industry. Industrial fabric laser cutting machine is also known as industrial laser fabric cutting machine, industrial fabric laser cutter, industrial laser fabric cutter, commercial fabric cutting machine, industrial garment laser cutting machine, industrial laser garment cutting machine, industrial garment laser cutter, industrial laser garment cutter, industrial textile laser cutting machine, industrial laser textile cutting machine, industrial textile laser cutter, industrial laser textile cutter, industrial laser cloth cutting machine. It is an industrial CNC laser cutting system with CO2 laser tube for fabric cutting with high speed and high quality.

What Is Multi-Layer Fabric Cutting Machine?

The multi-layer fabric cutting method is exactly how it sounds. Before being feed into the cutter, fabrics are spread on the table by hand or by auto fabric spreader layer by layer. Then with the assistance of the nesting software system, this computerized cutting machine cuts fabric layers as per the command given in the computer system.

What Is Co2 Laser Cutter?

A CO2 laser cutter uses gas to power up and generates light when electricity runs through a gas-filled tube. Since CO2 laser beams are usually easily absorbed by fabrics, that would lead to a part of the fabric heating up and getting vaporized. The CO2 laser cutter can be used on different fabric types, including jeans, fleece, lace, silk, cotton, Alcantara, softshell, polyester, linen, and felt. We have a very detailed introduction of the Co2 laser cutting machine cutting textiles and fabrics in this article. You can understand more.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.