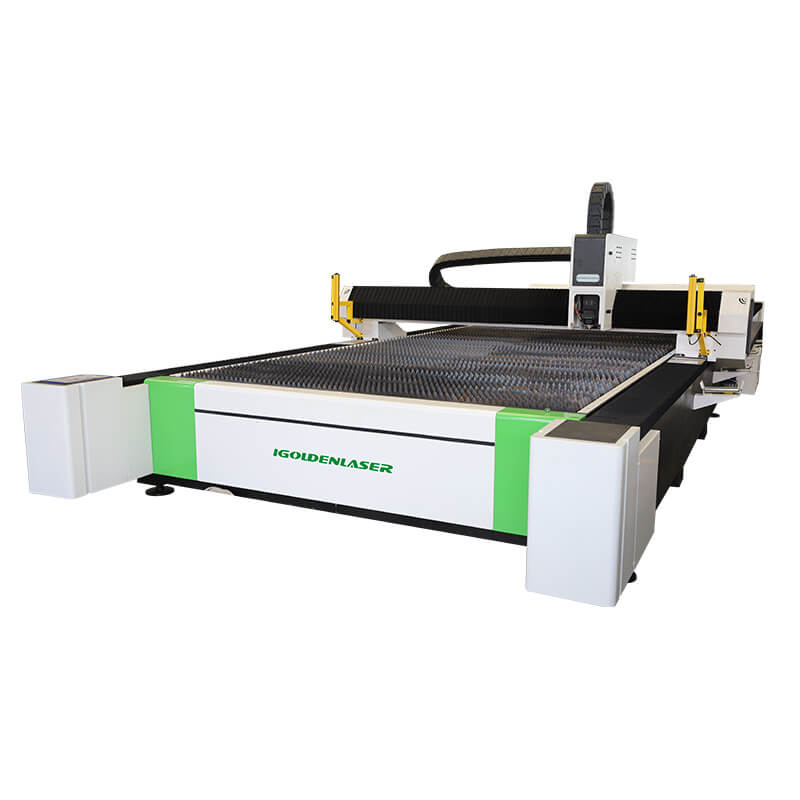

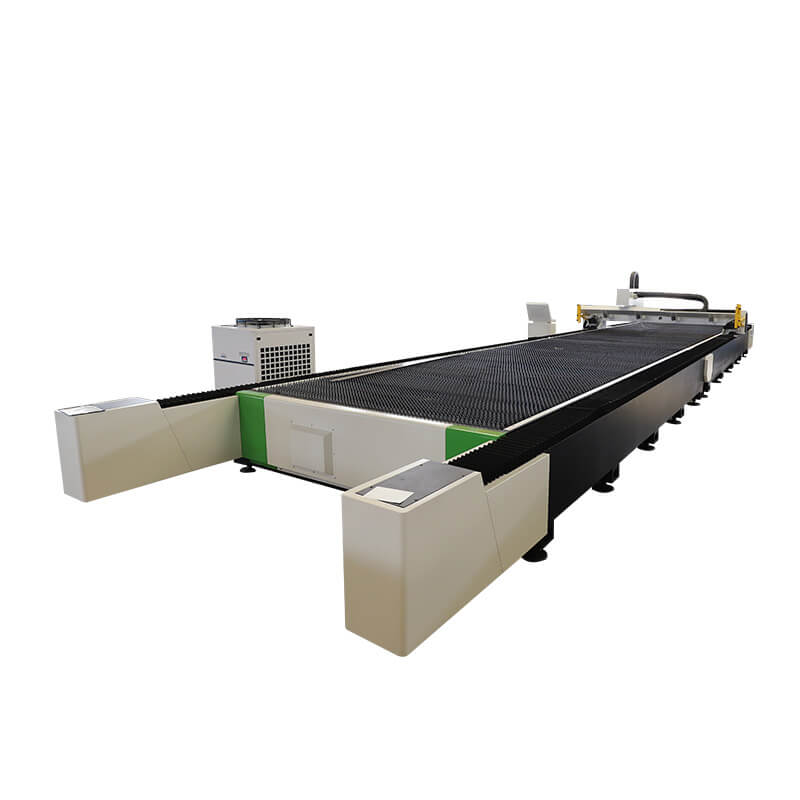

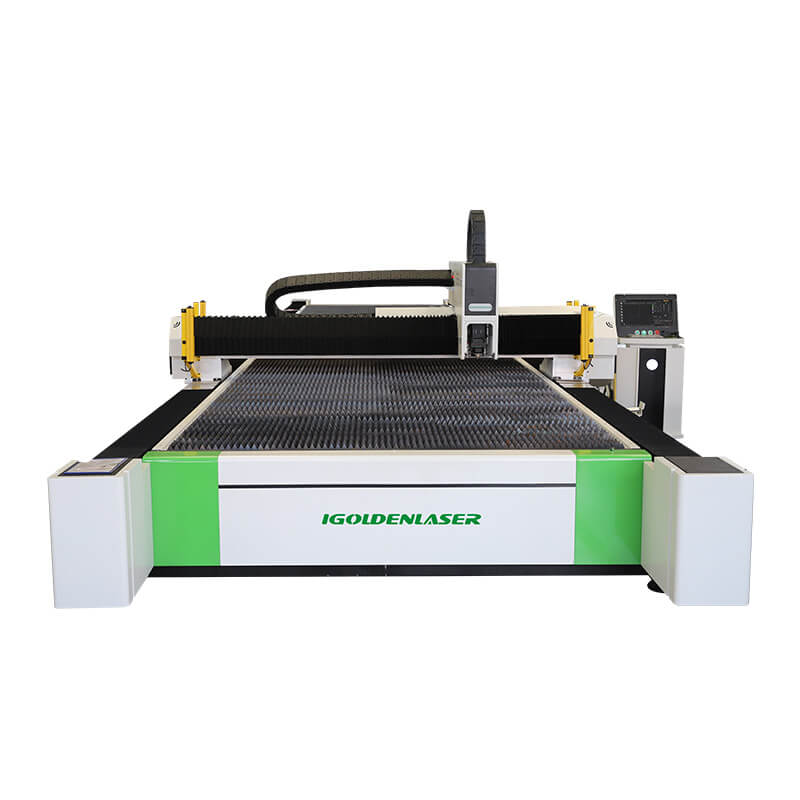

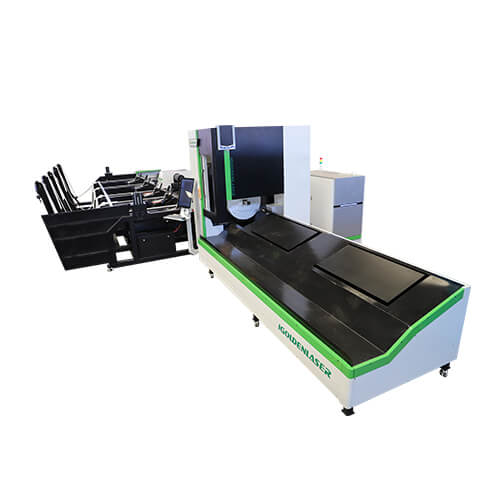

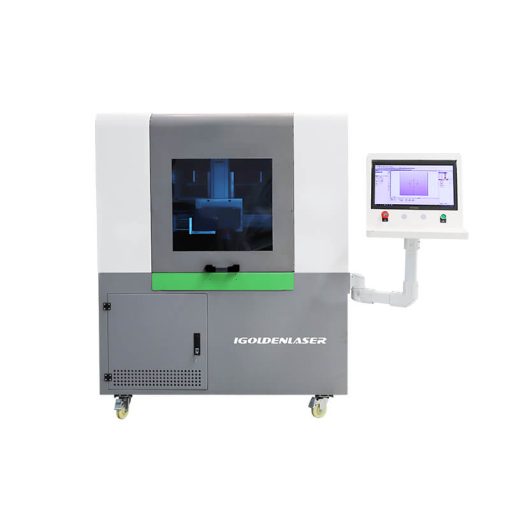

iGR-G(+R) Series

Large Format Flat Laser Cutting Machine

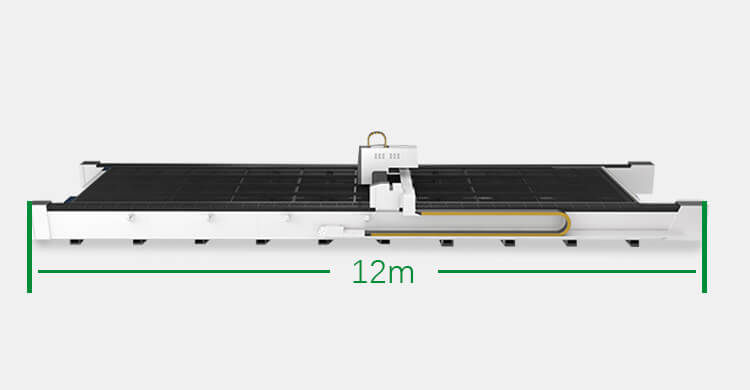

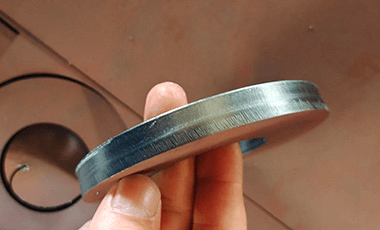

iGOLDENLASER iGR-G(+R) Series Large-area fiber laser cutting machines use a modular design, quickly expand metal cutting regions, and reduce transportation costs. It can realize the timely processing of various graphics and characters and is user-friendly and straightforward. Customized formats are supported.The maximum processing format can reach 2500mm*12000mm, and the maximum thickness of the plate can be cut to 25mm. It can meet the requirements of large-format processing. Customized formats are supported.

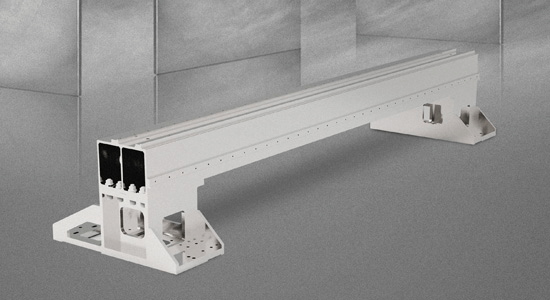

G series large format flat plate laser cutting machine, heavy welding bed, ultra-high load bearing, to ensure maximum operating accuracy; 12m full plate cutting, fearless large plate, ultra-high power, up to 30000W, efficiency doubled, long-term batch stable cutting thickness of 20mm or more thick plate, a wide range of processing materials;

Wixer –

I selected a lot of CNC laser cutting machine suppliers on the Internet, and finally, I chose IGOLDENLASER because it is very professional.

Mexico –

I love it. It’s been amazing so far. Thanks so much to you guys. I haven’t got many amazing pictures yet but will sent over what I have.

Ellie Gallagher –

I like this 12000w CNC laser cutting machine very much. My workers can quickly operate this machine, and the work efficiency of this new machine is twice that of the old machine.

Guthry Gamaleri –

The price of this fiber laser cutting machine is very affordable, thousands of dollars cheaper than my friend’s price, and the processing quality is also very good.

Arbella Gapski –

Machine is running flawlessly. I think I have spoken to at least 5 people here in Australia about the machine and have given them an honest answer on dealing with your business.

Demi –

I was hesitant about the investment, but this laser cutting machine has paid for itself within months. The accuracy is remarkable, and the speed is impressive. It has opened up new avenues for our business, especially in custom fabrication.