No products in the cart.

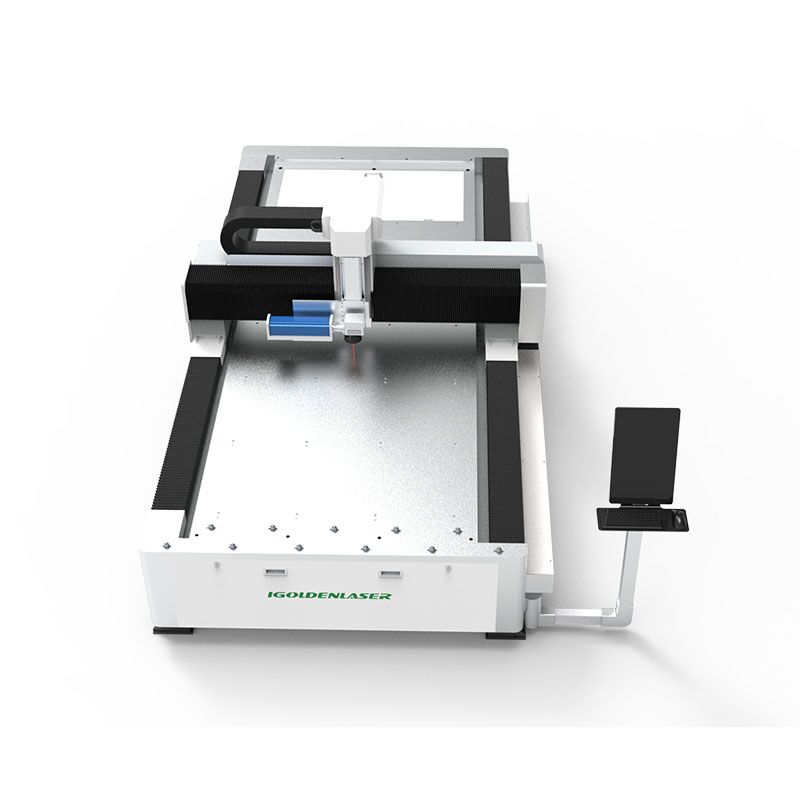

iGR-L(E)

Mirror and Stainless Steel Laser Sandblasting Machine

Laser etching machine is a new type of high speed and high precision laser frosting machine developed for the needs of shading glass, decorative glass, intelligent mirror and other industries. The device can be used for mirror paint and mirror removal, Low E glass film removal, one-time processing to achieve a hiding effect, and laser drilling.

This machine is not only suitable for white glass, colored glass, mirror, but also suitable for most plastics and stainless steel, alumina, copper and other alloy materials surface marking.

The laser glass sandblasting machine can be widely used in architectural decoration, household goods, electronic products, art production and other fields: whether it is a glass screen for high-end home, a bathroom mirror, a smart mirror, a makeup mirror, a glass curtain wall for modern buildings, or a protective glass for precision electronic products, this machine can achieve a perfect surface treatment effect. At the same time, it is also suitable for the personalized customization market to meet consumers’ pursuit of unique design and quality.

Reviews

There are no reviews yet.