Buyer Guide

Laser Cutter and Engraver for Wood Metal

The advent of laser technology has brought about a revolution in various industries, including woodworking and metalworking. Laser cutters and engravers have become indispensable tools for professionals and hobbyists alike, offering unparalleled precision and versatility. This comprehensive guide explores the features, benefits, and applications of laser cutters and engravers for wood and metal, providing valuable insights for those looking to enhance their craft.

Laser Cutter and Engraver for Wood Metal

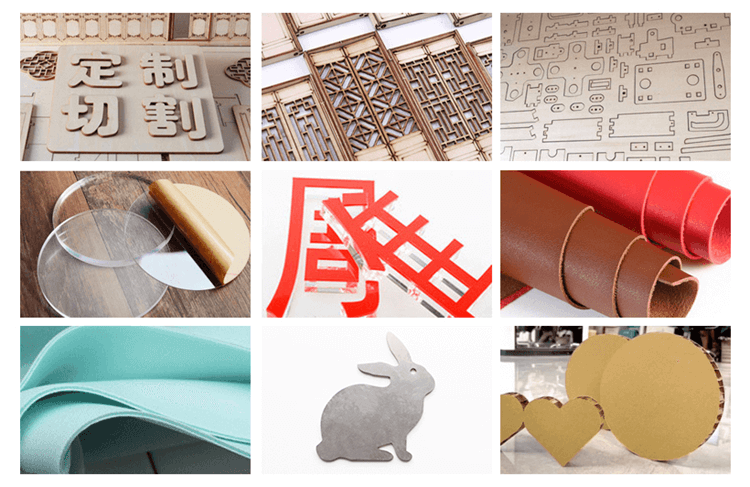

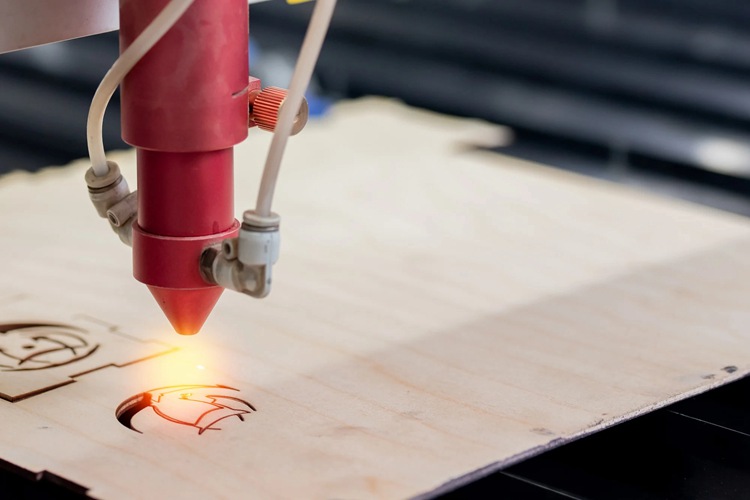

The CO2 laser machine is the general term for laser engraving machines, laser cutting machines, and laser marking machines. The laser machine uses its high-temperature working principle to act on the surface of the processed material, and at the same time draws patterns and texts required by customers based on the graphics input into the machine. This laser cutting machine wood and metal can cut a range of materials, including wood and metal. It has a powerful CO2 laser source and a large work area, making it a popular choice for small businesses that need to work with both materials.

laser engraver for wood

Laser wood cutting is a process that uses a focused beam of light (laser) to cut through wood with high precision. The laser beam vaporizes the wood along the cutting path, resulting in clean and precise cuts. This non-contact method minimizes material waste and allows for intricate designs.

Features Laser Cutter and Engraver

- Dual laser heads: Some mixed laser engraver machines feature dual laser heads that can perform both cutting and engraving functions simultaneously, allowing for faster processing times and improved efficiency.

- Laser power: The laser power of the machine will determine the thickness and type of materials that can be cut or engraved. Look for a machine with a high-powered laser to handle a wide range of materials.

- Work area: The size of the work area will determine the size of the materials that can be cut or engraved. Consider the types of projects you’ll be working on and choose a machine with a work area that can accommodate your needs.

- Software compatibility: The software that comes with the machine will determine the level of control and precision you have over the engraving and cutting process. Look for a machine that is compatible with popular software programs like CorelDRAW, AutoCAD, or Adobe Illustrator.

- Ease of use: The machine should be easy to use and operate, with intuitive controls and a user-friendly interface. Consider the level of experience you have with laser engraving and cutting, and choose a machine that matches your skill level.

Benefits of Using Laser Wood Cutting

Enhanced Precision

One of the primary advantages of laser wood cutting is the enhanced precision it offers. The focused laser beam ensures that each cut is executed with exact accuracy, resulting in high-quality finished products.

Increased Efficiency

Laser wood cutting can significantly increase efficiency in the cutting process. The automation of tasks reduces the need for manual intervention, allowing for continuous operation and faster project completion.

Versatility

Laser wood cutting machines are incredibly versatile, capable of handling a wide range of wood types and thicknesses. Whether you’re cutting intricate shapes or creating detailed engravings, a laser wood cutter can do it all.

Cost-Effective

Laser wood cutting is a cost-effective solution for both small-scale and large-scale projects. It offers the same level of precision and versatility as traditional methods but with reduced labor costs and material waste.

Applications of Laser Wood Cutting

Custom Furniture

Laser wood cutting is ideal for creating custom furniture pieces. The precision and versatility of these machines allow for the creation of intricate designs and detailed engravings, resulting in unique and high-quality furniture.

Sign Making

The sign-making industry benefits greatly from laser wood cutting. These machines can cut and engrave a variety of wood types, allowing for the creation of detailed and customized signs.

Decorative Items

In the decorative items industry, laser wood cutting is used to create precise and detailed components. The ability to automate tasks such as cutting and engraving ensures that each piece is crafted with exact accuracy.

Model Making

Laser wood cutting is invaluable in model making. It allows for the rapid production of components with high precision, enabling designers and engineers to create detailed and accurate models.

Art and Craft Projects

For hobbyists and artists, laser wood cutting offers the ability to create intricate art and craft projects. From detailed engravings to custom cutouts, these machines provide endless creative possibilities.

Laser Cutter and Engraver for Wood

There are laser CNC machines available that can cut both wood and metal. These machines typically use fiber lasers, which are capable of cutting through a variety of materials with high precision and speed. When it comes to cutting wood, laser CNC machines can produce intricate designs and patterns with ease.

Laser Engraver for Metal

They can cut through a variety of woods, including hardwoods, softwoods, and engineered woods. For metal cutting, laser CNC machines can cut through a range of materials, including steel, aluminum, copper, and brass. They can be used to cut thin sheets of metal quickly and accurately, making them well-suited for applications such as metal fabrication and prototyping.

When selecting a laser CNC machine that can cut both wood and metal, it’s important to consider the power output and cutting capabilities of the machine. The power output will impact the thickness of the materials that can be cut, while the cutting capabilities will determine the level of precision and detail that can be achieved.

Choose CNC Laser Cutter Service or Buy a Laser Machine?

CNC laser cutter service refers to the services that laser machining companies provide to cut and engrave products with various laser machines based on their customers’ requirements.

Choosing the laser cutting service or a laser machine has respective pros and cons, and suitable for different conditions.

Laser cutter service is very convenient for companies that occasionally require a small quantity of laser-cut products. It is not worthwhile for such companies to spend thousands of dollars to buy a laser cutter engraver for merely occasional use. So they can pay the laser cutting service providers the processing fees for laser cut and engraved products. But the laser cutter service quality is not consistent. So you need to spend some time and energy to find a qualified laser cutter service provider.

However, if your company lives on the sales of laser-cut or laser-engraved products, buying a laser machine is your best choice. The excellent flexibility, processing quality, and long service life of laser machine help improve your work efficiency and increase revenue.

Pingback: Laser Wood Engraving Ideas & Projects