Uncategorized

Laser Cutting Machine for Jewelry

The jewelry industry of today has accepted personalization as its chief supporter. More individuals are now interested in and attracted towards marking and engraving their pieces of jewelry. Likewise, manufacturers, retailers, and designers of jewelry are now in search of dependable solutions for making cuttings of high precision on precious metals. The use of laser systems with high power cutting, engraving and marking abilities has been adopted as an alternative method to the traditional means of welding, engraving, and cutting of metals.

Jewelry Laser Cutting Machine

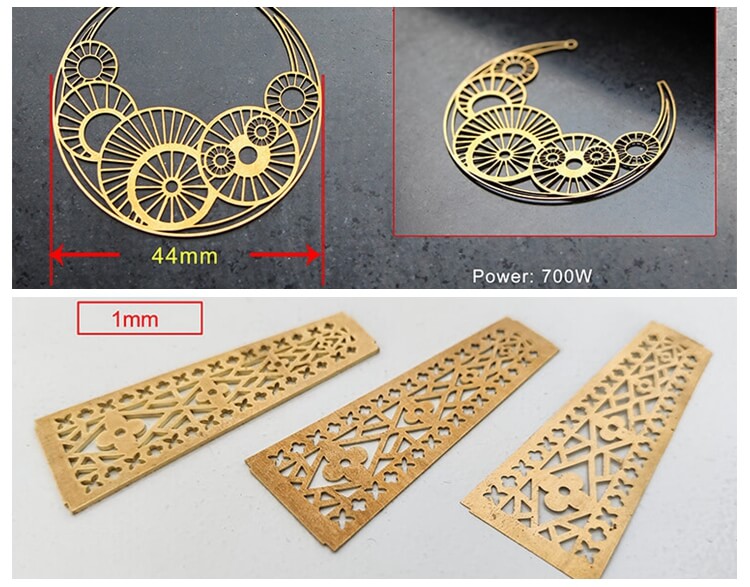

Laser cutting machines for jewelry offer exceptional precision and accuracy, allowing for intricate and detailed cuts. The focused laser beam enables clean and smooth edges without causing damage or distortion to the material. This level of precision is crucial for intricate patterns, filigree work, and delicate jewelry designs.

Laser cutting machines for jewelry offer design flexibility, allowing you to create custom shapes, patterns, and engravings. They can replicate intricate designs consistently, making them suitable for producing multiple pieces with uniform accuracy. The machines are typically computer-controlled, enabling you to import or design digital files for cutting or engraving.

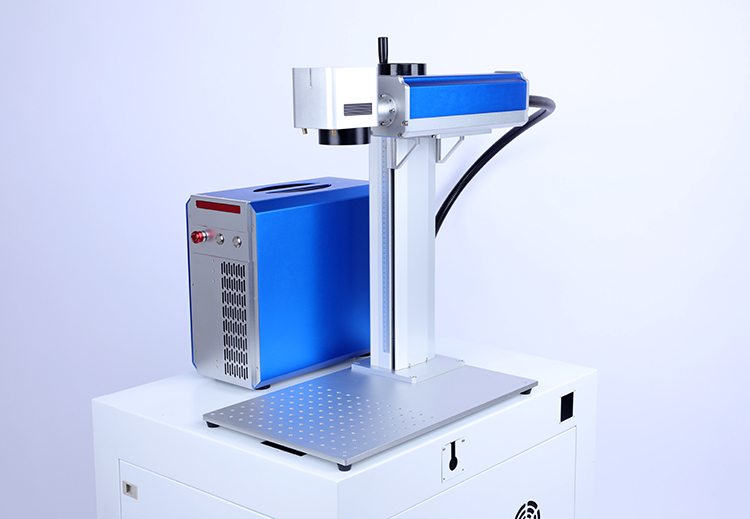

The Laser Cutting and Marking Machine is a high-precision device that utilizes advanced laser technology to perform cutting and marking functions on gold and silver materials. This machine is specifically designed for the jewellery making industry, allowing users to produce intricate and complex designs with ease.

The laser beam emitted by the machine provides clean and precise cuts with no burrs or rough edges, ensuring that each piece has a smooth and professional finish. Its user-friendly control panel and customizable settings provide operators with flexibility and ease of use, enabling them to achieve consistent and high-quality results. This Jewellery Laser Cutting & Marking Machine is an ideal solution for businesses and individuals looking to increase productivity, efficiency, and quality in their jewellery production processes.

Jewelry designers and manufacturers are continually looking for reliable solutions for producing precision cutting of precious metals. Fiber laser cutting with high power levels, improved maintenance and better functionality is emerging as a top choice for jewelry cutting applications, particularly applications where superior edge quality, tight dimensional tolerances and high production is required.

With the jewelry laser cutting system, you can:(Necklace) Interlocking Monograms;(Necklace) Circle Monograms;(Necklace) Name Necklaces;(Earrings) Complex Custom Designs;(Necklace) Pendants & Charms;(Necklace) Intricate Patterns;(Pendants and bracelets) Custom One-Of-A-Kind Parts

Laser systems are capable of cutting, engraving and marking several metals, including gold silver and others. With our laser systems, a variety of materials of various thickness can be worked on to create complex shapes. They maximize precisions, cut flexible and offer a cost-effective, high accuracy cutting, engraving and marking solutions. It is also an avenue for jewelry designers to achieve maximum freedom to create fantastic shapes, far better than what the traditional cutting methods offer.

Jewelry laser cutting machines can work with a variety of jewelry materials. They can cut and engrave metals such as gold, silver, platinum, stainless steel, and titanium. Additionally, they can handle non-metallic materials like gemstones, acrylic, wood, leather, and more. The machine’s capabilities and power will determine the range of materials it can effectively process.

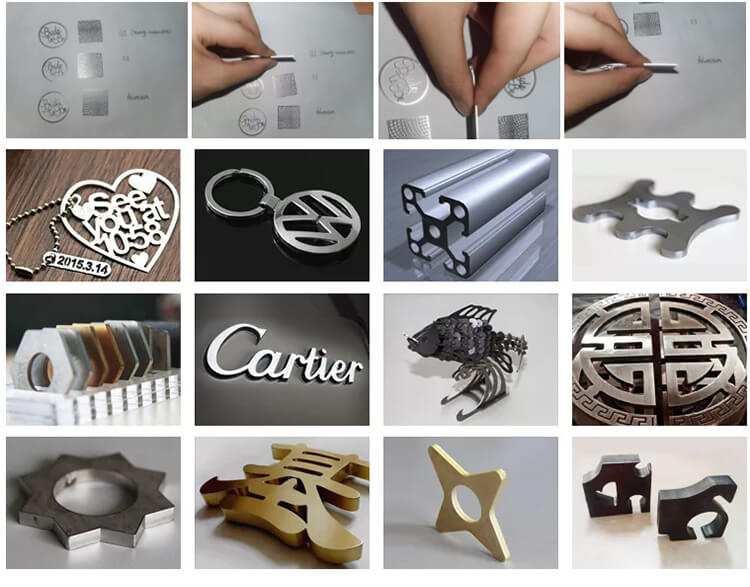

Mini Compact Precision Laser Metal Jewelry Cutter Applications

Laser metal jewelry cutter is used in metal jewelry industry, such as rings, earrings, necklaces, bracelets, brooches, pendants, cufflinks and other personal ornaments made of stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating zinc plate, gold, silver, copper, colored stainless steel and some precious metals.

Mini Compact Precision Laser Cutter for Metal Jewelry Projects of Silver, Gold, Copper, Stainless Steel

Fiber Laser Cut Metal Jewelry Projects.

Jewelry Laser Engraving Machine

A jewelry laser engraving machine is a specialized device used to etch or engrave designs, patterns, or text onto various types of jewelry using laser technology. These machines use a highly focused laser beam to remove material from the surface of the jewelry, creating precise and detailed engravings.

Jewelry often requires intricate and precise engravings, and laser machines excel in providing that level of detail. Look for a machine with high resolution and accuracy to achieve fine and intricate designs.

Jewelry engraving machines typically use either fiber lasers or CO2 lasers. Fiber lasers are commonly used for marking and engraving metals like gold, silver, and stainless steel, while CO2 lasers are more suitable for engraving non-metallic materials such as wood, acrylic, or glass.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.