No products in the cart.

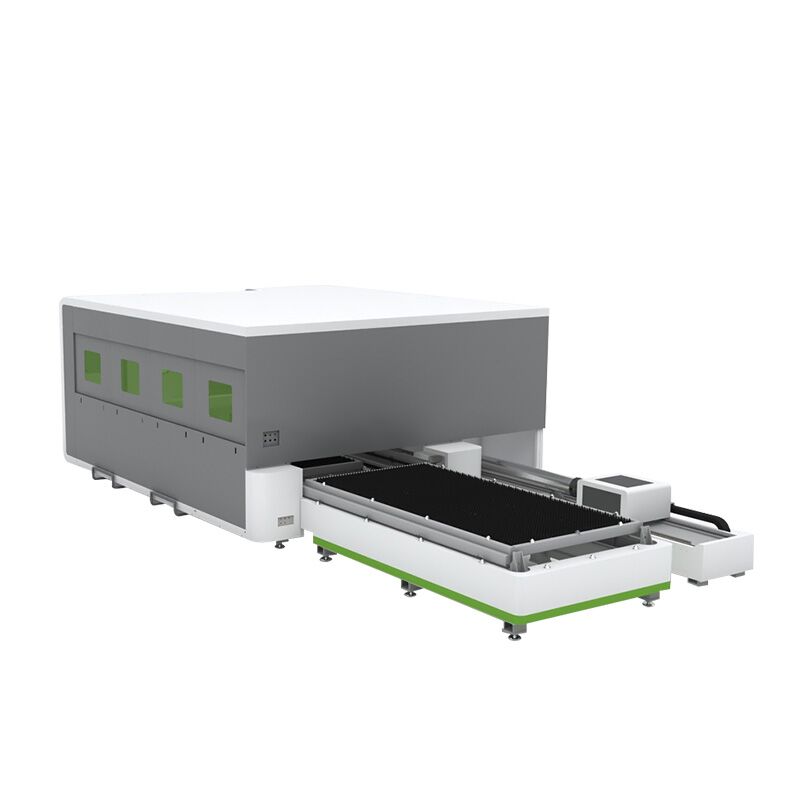

iGR-PH(TP)

Fiber Laser Cutting Machine for Metal

This Fiber laser cutter is a type of automatic industrial laser cutting system with 12000W laser generator and CNC controller for sheet metal fabrication with high speed and high precision. It is a high power laser cutting machine for thicker metal sheets, including carbon steel sheets, stainless steel sheets, aluminum sheets with the maximum thickness of 50mm, and the maximum cutting thickness of non-ferrous metal sheets (such as copper and titanium) is 20mm. The maximum cutting speed for thin metal sheets can be up to 80m/min.

The exchange platform fiber laser CNC sheet metal laser cutting machine adopts totally enclosed laser protective cover, ensuring the safe, stable, efficient and high-precision operation of the sheet metal cutting. Exchange platform helps improve production efficiency greatly.